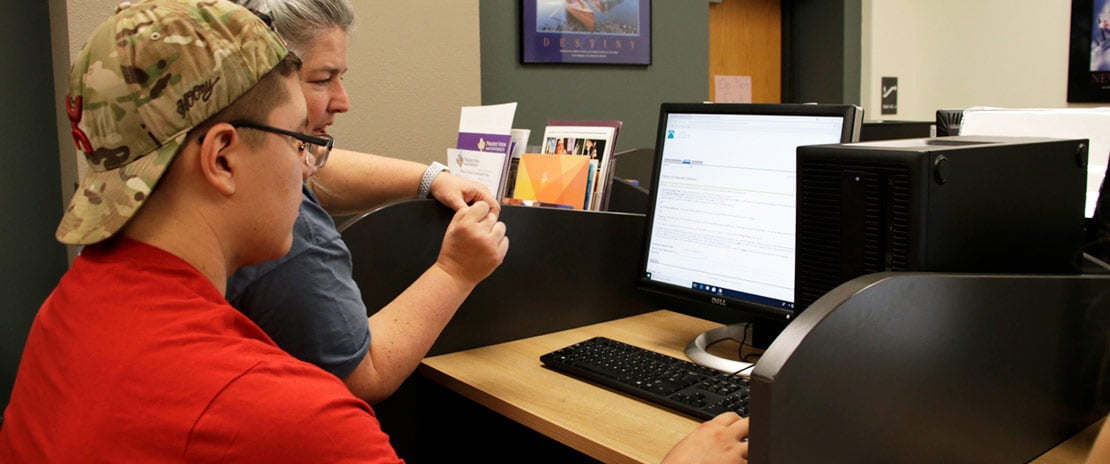

Types of mechanical seal

Mechanical Seal: Principle, Types, Diagram, Functions, Applications. Mechanical Seal Types. Various Types of Mechanical Seals for Centrifugal Pumps.MECHANICAL COMPONENTS.

A Comprehensive Guide to Mechanical Seals

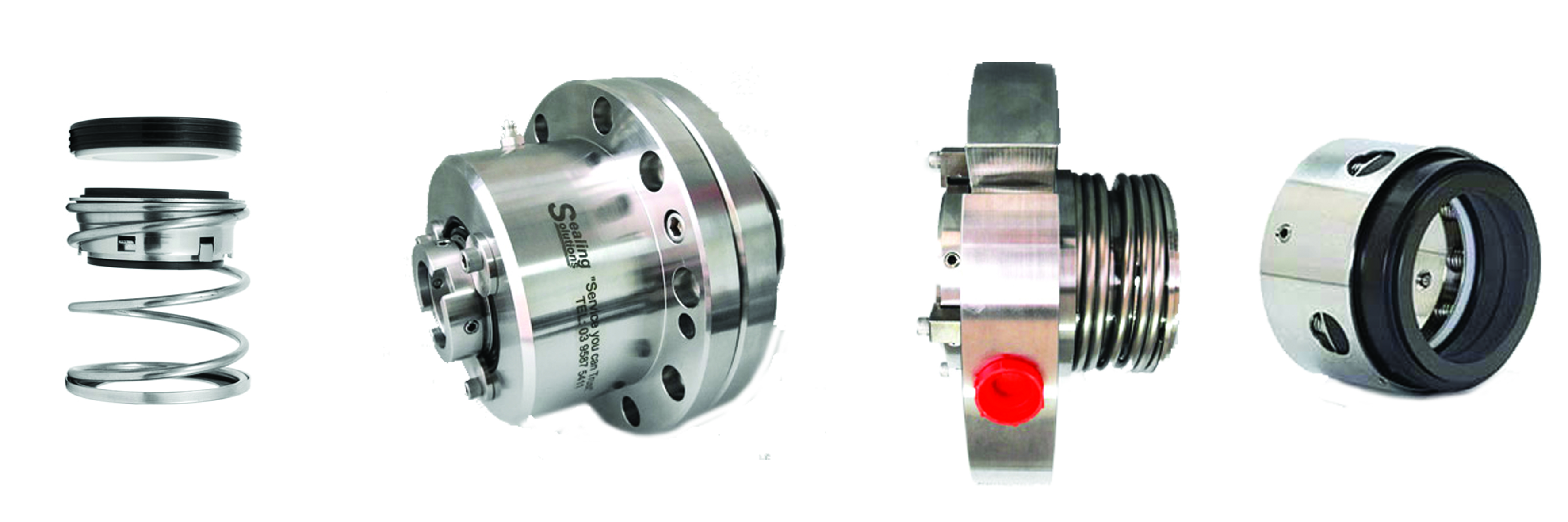

Understanding the advantages and limitations of each technology can greatly reduce . a) Cartridge Seals: .) and stationary parts (casing, stuffing box). 12 Types of Mechanical Seals for Pumps Let’s look at the 12 main mechanical seal types you can .Straight-Through Labyrinth Seals. Balanced seals. Mechanical Seal Basics. Metallic bellows mechanical seals consist of a flexible metal element that is typically made from stainless steel or other corrosion-resistant alloys. They play a vital role in maintaining the integrity and efficiency of industrial machinery by sealing fluid passages and preventing leakage of liquids or . Unbalanced seals may also exhibit less product leakage due to tighter control of the mask, but the result will exhibit a much lower mean time between failures.As mechanical seals act as pivotal enablers in containing and preventing leaks in several types of machinery used underwater – from oil drilling rigs to submarines -, their failure due to high pressures could not only result in substantial financial losses but also considerable environmental harm. Drawbacks of Pusher Type Mechanical Seal.Unbalanced mechanical seal types are often used as a more economical alternative to more complex balanced seals.

Non-pusher seals.

The 4 most common mechanical seal types and variations

Additionally, mechanical seals can reduce product waste, wear, and maintenance requirements, which can make these sealing options more cost-effective and efficient.

UNDERSTANDING MECHANICAL SEALS

basic four components (Images courtesy of. Shaft Seals For most pumps a decisive element for the quality of the pump during its lifetime is a good .

Seal (mechanical)

Although these devices use similar terminology, industrial standards classify them in a category separate from that of the seals generally referred to and employed in industrial and commercial applications—i. From options like mechanical seals, lip seals, packing seals to labyrinth seals – each type brings unique strengths that fit specific applications and operational contexts. These include the type of seal, the specific application, the operating conditions, and how well the seal and the equipment are maintained. Conventional seals. By understanding these common types of double mechanical seals, you will be able to select the most appropriate sealing solution for your application. In this case, an appropriate barrier fluid must provide sufficient lubrication and cooling between . Single Mechanical Seals.Types of mechanical seals. They are self-aligning, an attribute that makes them highly versatile and effective in accommodating significant shaft misalignment and movement. There are three main types of mechanical seals available depending on the needs of a particular application. These fluids serve to create a conducive environment for the seal, optimizing its functionality and lifespan.Types of Labyrinth Seals 1. An stable and complete .

Shaft Seals: A Comprehensive Guide

Here are some of the most common types: Single spring seals.Gas-lubricated double mechanical seals are particularly suitable for applications where zero leakage is of vital importance or when dealing with hazardous chemicals.Learn how mechanical seals work by sealing process fluids in or out with rotating and stationary faces. The ratio between the forces which are closing the . Under ideal conditions, a mechanical seal could last several years.The lifespan of a mechanical seal can vary greatly depending on several factors. These include: Cartridge.Its design incorporates a series of annular rings, which create a complex path—the “labyrinth”—for the fluid or gas to navigate . The most common design types are Rubber Diaphragm, Rubber . in a pumping system), containing pressure, or excluding contamination.Mechanical seals usually don’t require maintenance, have a simple and cost-effective design, and improve the pump’s lifespan.

Introduction to Mechanical Seals

In last month’s article, we discussed the four basic components found in every mechanical seal, as well as reviewed the different . Let’s know the highlights of various types of seals and their benefits and limitations. Mechanical Seal. Each type has its unique features and applications, ensuring reliable performance in various industrial settings.

How many types of mechanical seals are there?

All types of mechanical seals generate heat from friction between the moving surfaces, and a cooling fluid — called a flush — circulates around the seal to remove the heat. LEARN MORE ABOUT DYNAMIC SEALS. A Glimpse of Pusher Vs Non-Pusher Type Mechanical Seal.

Understanding Mechanical Seals: A Must-Read Guide

Through the gap, the pressurized fluid in the casing might seep into the surroundings.There are several types of mechanical seals, including single-spring, multi-spring, cartridge, and bellows seals, as well as specialized variants like mechanical oil seals and various shaft seal types.This mechanical seal is a cartridge type.

They make the seal suitable for a particular application.

What is a Mechanical seal?

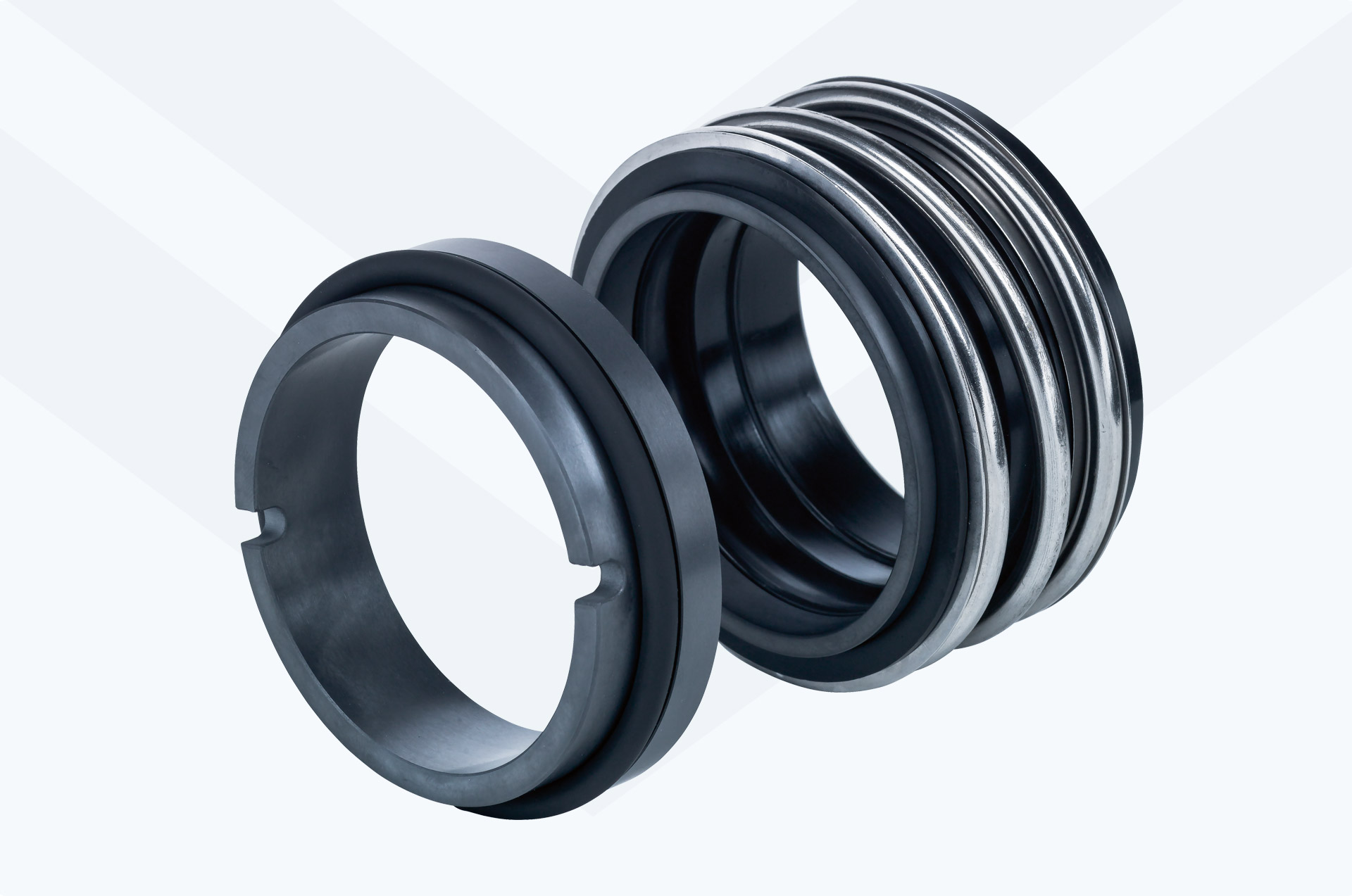

A single mechanical seal consists of two sealing faces, one stationary and one rotating. This essential tool gained popularity in the 1950s and was used .Seal types: Induction sealing or cap sealing; Adhesive, sealant; Bodok seal, a specialized gas sealing washer for medical applications; Bonded seal, also known as ., mechanical seals. A space between rotatory and stationary elements is required to avoid mechanical component wear and tear. Explore how these . For double mechanical . The fluids of the pump remain good for the existence of this device.

Mechanical seals according to EN 12756 (code system) For single mechanical seals there is a distinction drawn between standard (N) and short (K) types. Single spring seals are the most common type of mechanical seal and consist of a single elastomeric bellow that provides the sealing . These seals are frequently used in water . However, in harsh operating conditions – .Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal.Mechanical seal types vary in design, setup, and how they disperse the hydraulic forces acting at their faces. Revising or adding the correct seal plan can often significantly extend seal .

This section will focus on the most common bellows mechanical seal types: metallic, elastomeric, and PTFE (Polytetrafluoroethylene) bellows.

Lubricating film Process pressure Atmospheric pressure .Discover everything you need to know about mechanical seals – from their functions and types to applications, temperature ranges, and common materials. Unbalanced seals are not recommended for high pressure . Unbalanced seals. Lubricating film Lubricating film (≈1µm) Lubricating film too thick Lubricating film too thin . Elastomer bellows seals, also known as rubber bellows seals, provide a cost-effective solution for a variety of applications.Critiques : 5

Types of Mechanical and Industrial Seals

These seals are located in the asset’s stuffing box or seal chamber. Metallic Bellows Mechanical Seals. The seals are installed in pumps in a wide .Temps de Lecture Estimé: 10 min

The Fundamentals of Mechanical Seals

Find out the factors that . Chesterton Company) The components of a mechanical seal .Mechanical Seal.types of mechanical seals, showing the same.

Mechanical seal technology and selection

An end-face mechanical seal is a device on a rotating shaft used to keep contaminants out and fluids in.This section will discuss various seal types and provide guidance on selecting the appropriate barrier fluids for each. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result can exhibit much lower mean time between failure. The flush provides constant lubrication when the product flow is not sufficient; the fluid flow is intermittent (e.Mechanical seals differ from other types of seals in that they involve rotating and stationary components, as well as a spring.(3) Pay attention to whether there are abnormal phenomena during machine operation, such as vibration or bearing damage, which will affect the use of the . A straight-through labyrinth seal is a type of non-contact seal that is commonly employed within various industrial components to prevent leakage. When it comes to ensuring the efficient and reliable operation of rotary equipment, mechanical seals play an indispensable role. The common types are: Cartridge; Conventional; Pusher; Non-pusher; Balanced and Unbalanced. Cartridge seals. It prevents the fluid moved through an asset, most often a centrifugal pump, from leaking. The design, arrangement and . Mechanical seals are usually end-face seals or rotating-face seals, but in some designs they can be circumferential or even a hybrid of lip-type seals.

How to Choose the Barrier Fluid for Mechanical Seal

Different seal types within these groups are described with their respective design, materials and applications.In mechanical seals, in addition to the closing force generated by the springs or bellow, an hydrostatic force generated by the fluid pressure acts on the seal ring.When to use different seal material types 5. They may use heat exchangers, separators, flushing or quenching, and many other mechanisms, depending on the type of seal and operating environment.December 9, 2023.Mechanical seals come in various types, each designed to meet specific operational requirements and conditions. Dynamic Seals Information. Buffer fluid is located between two tandem mechanical seals in what’s known as a double seal arrangement.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the . The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.Seal piping plans are designed to provide a clean cool environment for the mechanical seal and the seal chamber. Understanding how they work will help the professionals to select the appropriate type and their correct application. Elastomer Bellows Seals. Here are some of the most common types: Single .A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc. Unbalanced seals are not recommended for high . Common seal flush plans . As previously discussed the fluid pressure also penetrates between the seal faces, producing a lubrication film and generating an opening force.Mechanical Seal Types: There are multiple designs available for mechanical seal configurations. A centrifugal pump is a combination of rotary (shaft, impeller, sleeve. Dynamic seals . Furthermore, these seals have a critical role in .Seal faces can be lubricated by the process fluid or, with double mechanical seals, by a proper auxiliary fluid (see chapter relevant to configurations).

Pump Seals: Most Common Styles

Show all Dynamic Seals Manufacturers.

Back to Basics: Mechanical Seals

The most common seal types include the following: Balanced seals.Buffer fluid and barrier fluid are two types of isolating liquids used in conjunction with a mechanical seal.

Mechanical seals are precision-engineered devices designed to prevent leakage between two surfaces in relative motion, typically in rotating equipment such as pumps, compressors, and mixers.

Industrial shaft seals

Seals act as the interface between moving and stationary components.Examples of o-rings and radial shaft seals—Image Credit: Mechanical Research & Design, Inc.