Vial filling equipment

Pharmaceutical manufacturers have been trusting Syntegon for more than 60 years to process their vials reliably, safely, and efficiently. After the piercing, the stopper mechanically recloses .Meet the Microcell™ Vial Filler. Capping with standard and Lyo rubber stoppers.

Filling of vials in bulk.

Vial filling machines and processing solutions • Pharma • IMA Group

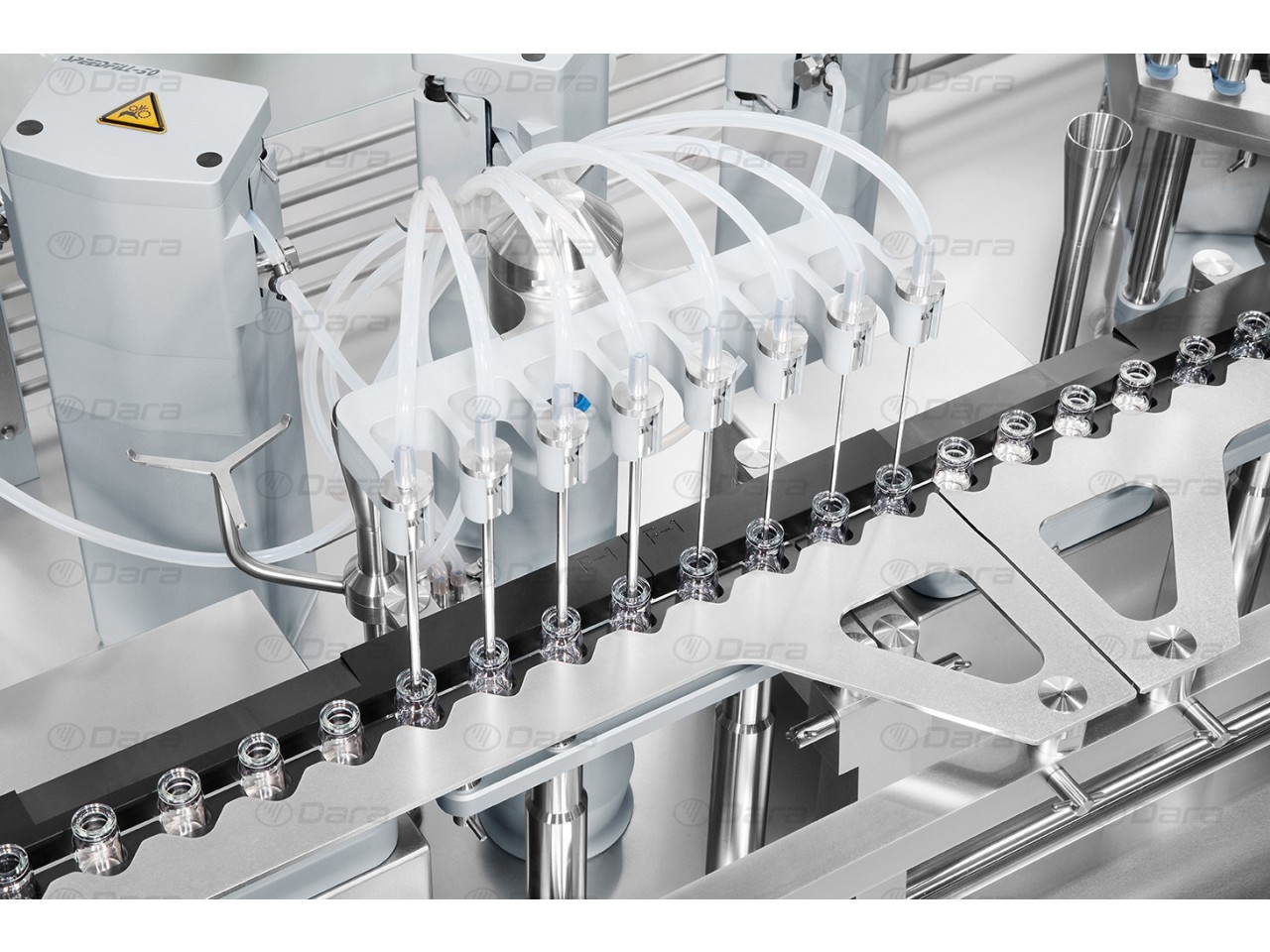

Our vial filling machines offer flexible solutions for packaging valuable liquid and powder . Connect With Us. Maximum of 12 open vials involved in filling and stop pering operations at the same time throughout the machine (1 vial (RVFM1), 4 vials (RVFM2), 12 vials (RVFM5).Normal filling and vacuum filling possible.Specialist in pure, clean and sterile applications.Dara Pharma offers compact machines for automatic filling and closure of vials, bottles, cartridges and syringes in glass or plastic, for liquid, semi-solid and powder products, in sterile areas or clean rooms. The GMP compliant system has been designed by aseptic fill/finish experts Flexicon Liquid Filling and containment experts Franz Ziel. Vatva GIDC, Ahmedabad, Gujarat GST No.

Vials Filling and Capping.The Crystal ® M1 is a manual equipment that can fill up to 180 AT-Closed Vial ® per hour.

Pharma vial filling

Syntegon offers internal and external cleaning machines for vials and other containers. Available with Syntegon peristaltic pump technology. 100% In-Process Control weight checking and inline inspection of vials, stopper insertion, and complete crimping. Vial transport with anthropomorphic vaporized H 2 O 2 compatible STAUBLI robot. Subscribe to our newsletter to stay up-to-date with the latest company news. Vial filling machines are cGMP compliant for use in cleanrooms.Most of Universal’s semi-automatic filling equipment requires only a compressed air supply.

OPTIMA

Filling Machines

Laxmi Pharma Equipment.The right system for any bulk vial filling process. Output: Up to 120 vpm with double index configuration Up to 90 vpm with single index configuration.

Liquid Filling Machine Manufacturer

Automating the filling process keeps decontamination and changeover times between products low – as little as 15 minutes with Aseptic Filling Workcells from Cytiva. Learn more about their proven .The VERSA™ 110 Vial Filling system is an automated liquid handling workstation designed to meet or exceed these requirements.Vial filling machine and containment solution to fast track your cell, gene and biological therapies. Using the M1 Filling Station, the AT-Closed Vial ® are individually filled through the stopper, laser re-sealed and capped, while being manually transferred between the process stations within the critical area. The system has been designed for use in sterile and nonsterile filling applications for the pharmaceutical, diagnostic and biotechnology sectors. And from the production of ready-to-use packaging containers (RTU) to technologies for downstream processing. The Crystal ® XL1 is an automated equipment, capable of 100% IPC, which can fill up to 675 AT-Closed Vial ® per hour.Sterility matters across the entire aseptic process – before, during and after sterile filling. A mass-flow sensor operating according to the Coriolis principle in each filling section ensures 100% in-process control and precise filling operations. Cartridge filling.ROTA: Pioneer in Fill-Finish solutions More than 100 years ago ROTA started with the development of a 1st simple ampoule filling and closing machine. Learn about the features, benefits, and applications of their vial . Stay In The Know.

Vial Filling Machine for Pharmaceutical Production

Vial filling machine designed for campaign production with containment technology. Tacoma, WA 98409.

Intelligent equipment for sterile filling of vials in bulk

Click Here To Sign Up.

Vials Filling, Capping & Sealing Machines

We are a manufacturer of aseptic vial filling machines & systems that ensure a sterile environment. This machine achieves a fill accuracy of better than ± . 24AABFL4855F1ZH. Vial filling machine designed for campaign production with containment technology.Flexicon offers a range of liquid filling and capping systems that grow with your business. By partnering with Optima, you also benefit from technologies, leaps in innovation, and tried-and-tested platforms .

Vials & Bottles.

How to fill sterile vials. In addition, an automated vial filler must offer an acceptable confidence value (CV) to meet or exceed tight regulatory standards and satisfy .Filling Equipment Company, Inc. Optimal accessibility.

Vial filling and closing line

These machines are complex systems that must be designed, . Flexicon’s portfolio ranges from stand-alone units for hand filling, through semi-automatic systems, to fully automatic filling, stoppering and capping machines. We provide you with comprehensive advice: from small-scale to high-performance systems for the aseptic and aseptically toxic filling of pharmaceuticals.

Filling of vials in bulk » Syntegon

After that, check the weight variation of filled vials for minimum 20 vials.

4110 S Washington St.Pharmaceutical vial filling machines perform a critical function in the pharmaceutical production chain: liquid filling into vials and bottles.BAUSCH offers flexible solutions for packaging liquid and powder pharmaceutical products in vials and bottles.

Sterile Linear Vial Filling Machines & Packaging Equipment

Benefits: Highly compact. Collect filled 20 vials from the equipment, measure gross weight & tare weight of vials . Washing, Sterilizing, Filling and Closing of Vials in Bulk. dosing volume based on a water based product. This aseptic equipment is based on a modular design, this being one of its distinctive features at a technological level, since this allows it to be . 120 vpm (double index) Up to 75 vpm: Vial transport system . manufactures packaging machines, filling machines and bottle capping machines that set the standard for the packaging equipment industry. GENiSYS C is an advanced, yet compact, filling and closing system for automated processing of vials, syringes and cartridges.Dosing via a peristaltic, rotary piston, or pumps. Technologies for filling, statistical or 100% weight check, capping and aluminium seals . Our modalities of focus: The offering is agnostic and appropriate for small molecules, biologics, viral vectors, mRNA, and other . We custom design and manufacture fill-finish equipment that precisely packages liquids and powders into vials, syringes, bottles, nests, ampoules, IV bags, and other containers. Easy format changeover. The Apollo II Dimmable Liquid Viewer provides a simple method for the detection of visible particles in transparent glass ampoules, vials, and bottles. The Crystal ® L1 is a semi-automated equipment that can fill up to 500 AT-Closed Vial ® per hour. Apollo II Dimmable Liquid Viewer. Up to 75 vpm: Output with 100% IPC: Max.The very compact and versatile design of IMA Life injectable vial filling machines, allows for suitable integration under isolator or different containment solutions . To prepare the batch, the bulk product is connected to the AT-Filling Kit™, the dosing system and laser control unit are calibrated.

Microcell vial filler

They offer efficient, high-precision filling for various vial sizes.25: 500: Filling accuracy with volumetrics pumps: ± 0,5% on nom.Benefit from industry expertise with OPTIMA – times 9. We have installed more than 1,500 vial filling machines all over the world.Bausch+Ströbel offers state-of-the-art vial processing systems for various applications, such as vials to infusion bottles, with high filling precision, gentle container transport and reliability.

View Product >. We believe that many years of experience and expert knowledge about your industry are essential to collectively create the best solutions for your individual requirements. Machine finder.Functioning principle. Le changement de produits se fait rapidement et sans outils, . Automating the process improves accuracy, versatility and reliability. Pharmaceutical vial filling machines ensure volumetric consistency, reduce product loss, and feature built in quality control in the form of volume checking.

Aseptic Filling Solutions

Vial filling machine manufacturers produce vial filling machines for use in several industries. Today, the machines .

Aseptic Fill-Finish Packaging Machines

Vial Filling Machines. Both the Microcell™ Vial Filler and SA25 Aseptic Filling Workcell can fill nested, pre-sterilized ISO vials from 2R to 50R.

Vial Filling Machines

Aseptic Small Batch Filling & Closing Machine

Liquid vial filling is a delicate process.Filling volume: 0. Home; Profile .Vials / Bottles. Syringe filling. Syringe Assembly Machines.During running, Check the Equipment speed synchronization with respect to powder filling assembly speed simultaneously ensure all the vials are being pass with filled powder.Cozzoli offers a wide range of automatic vial filling machines for the pharmaceutical industry.

Their user-friendly design and durable build make them vital for streamlined, quality-focused pharmaceutical production. Sign Up For Our Newsletter.Cellefill is a turnkey, small batch, vial filling machine with an integrated containment solution.Vials Filling, Capping & Sealing Machines. Both Automatic and Semi-Automatic filling machines are suitable for filling almost any liquid, from free flowing fragrances to drinks, through to viscous syrups and adhesives and even liquids containing particles such as food products.Cet équipement peut effectuer des remplissages de 0,1 à 250 ml et atteindre un rendement de 6 000 unités par heure. The vial filling machines are renowned in the pharmaceutical industry for their precision and reliability. Equipment can be combined with laminar flow units, RABS, and isolators.5% with speeds up to 120 bpm and can be customized to meet your needs.