Weld strength calculation examples

How to Determine the Shear Strength of a Fillet Weld

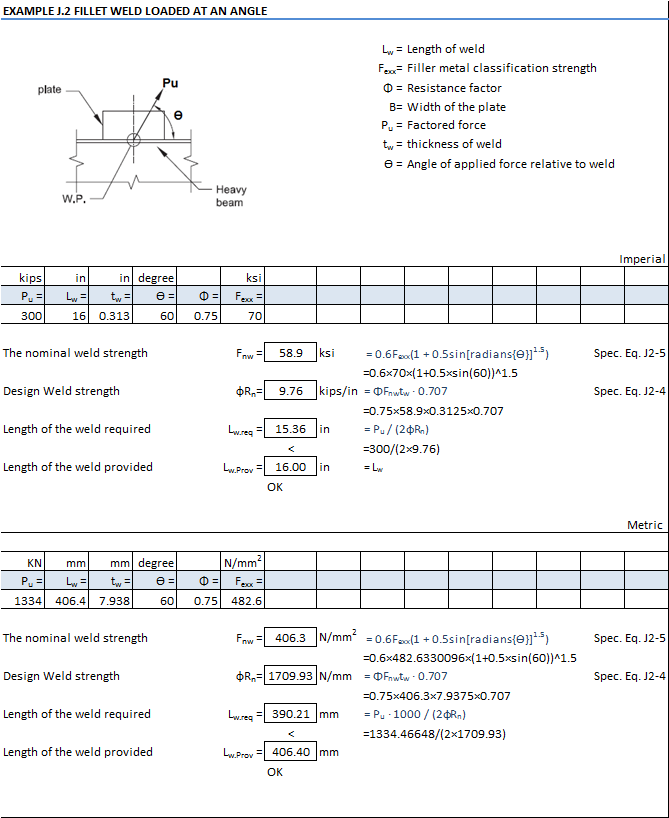

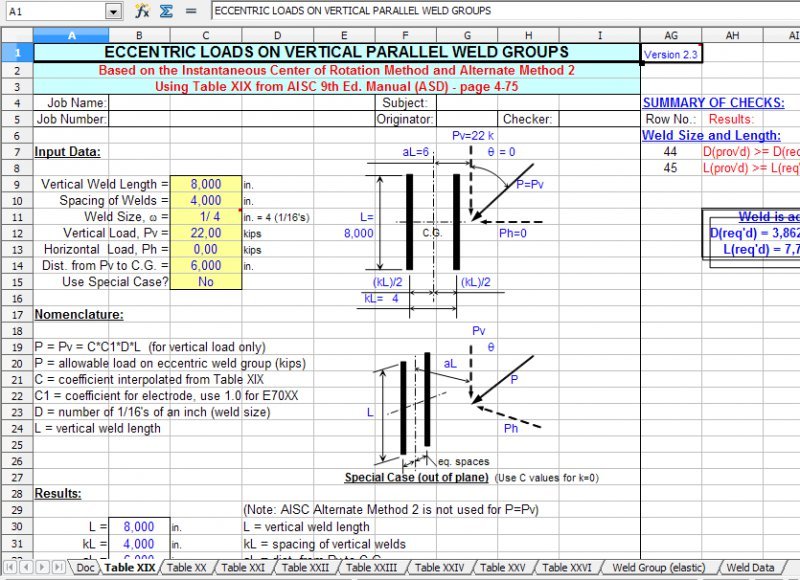

First, we rearrange the formula provided above to solve for F. Out-of-plane eccentricity is ignored.Table Basic Weld Calcs. The weld size is therefore 1,414. Table of Contents.468 mm, we will take the 3mm as the weld. Load Analysis and Design Methods.For example, we might consider only one inch of weld and determine the capacity of the weld and of the base metal, taking the lesser of the two, and continuing on to compute the capacity of the connection. Variables Associated With Welds. No increase in the effective area for design calculations is permitted for weld reinforcement.

How to calculate Welding Joint Strength?

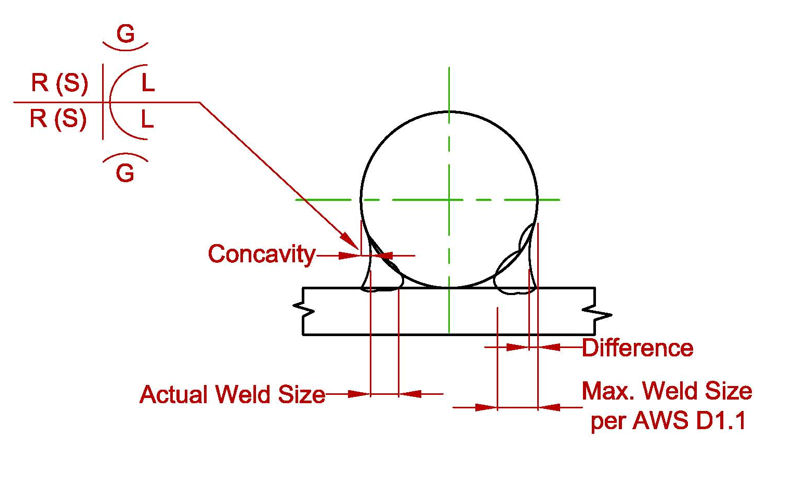

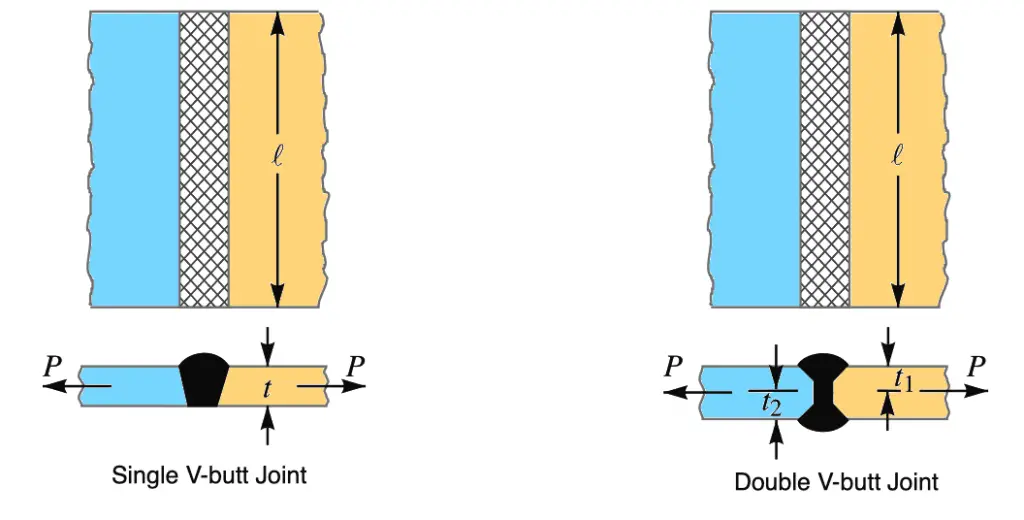

Fillet welds are one of the most common types of welds. Similarly, the strength of double butt joint welding is: P = (t_1 + t_2) l \sigma_\mathrm {t} P = (t1 + t2)lσt.2 weld-strength-calculation-examples Process Vessels Subject to Explosion Risk British Materials Handling Board.A fillet weld is the most common weld type in steel building construction. (For example, to determine the load a weld joint can carry ) I believe the below example would help all of you about its know how. So, from the fillet weld size calculation example we found that the required minimum weld.

The strength of stainless steel fillet welds using GMAW

RE: Aluminum Fillet Weld Design . A Partial Penetration Butt Weld is a type of welding joint where the fusion between the two pieces of metal being joined does not go all the way through the thickness of the material. where l is the length of the weld joint.

The maximum stress is similar but greatest at z .

{Download PDF} Weld Strength Calculation Examples

The welding calculator utilizes the above set of weld strength formulae to .How to calculate Welding Joint Strength? - ExtruDesignextrudesign.penetration groove weld shall be the thickness of the thinner part joined.Sample Strength Calculation. With this information, and knowing the deposition rate of the process, it is possible to determine the arc time (the length of time that an arc is burning and depositing weld metal) and the amount of welding consumables required to fill the joint.Load Capacity of Welds | Civil Engineering Xcivilengineeringx.how to calculate welding strength.P = t l \sigma_\mathrm {t} P = tlσt. Calculator; Updates; About; Contact; What are you solving for? Click one of the buttons below to let the calculator know what you are solving for. The weld size should be large enough to provide the required strength but not so large that it causes distortion of the metal.

707 x a x Lw x fw = 0.comRecommandé pour vous en fonction de ce qui est populaire • Avis

MITcalc

Calculate Weld Strength: Execute the calculation to determine the strength of the weld per inch.

5cm thickness, 0.U nless you are a design engineer you typically don’t have to worry about determining the strength of a weld.Example of torsion weld calc. Two statically loaded plates of known strength are fillet-welded together with specified weld geometry and weld strength. Fundamental Principles of Welded Connections.Variables Associated With Welds.2000 This work contains guidelines which provide available information as to the pressure capabilities of relatively weak process vessels in the event of an internal explosion. Weld throat: The weld throat is the thickness of the weld.4062 duplex grade. According to EN 1993-1-8, 4.Easily calculate the pitch between weld beads as well as bead quantities and lengths for your intermittent and stitch welding projects. Assuming that the bar was made of S235 steel, the maximum stress corresponds σ the yield strength of 235 N/mm 2.

Weld Stress Calculations

Guidance Principles.

Design of Fillet Welds According to EN 1993-1-8

637) and with a cap height of 0. The strength calculation can be well illustrated by an example: A rod is used, which is loaded on both sides with the force F . Given: Service Level Loads & Material: Reaction from Dead Load (RD) = 8. Capacities of Fillet Welds .comWelding Calculator App powered by voestalpinevoestalpine.Calculating the volume of a weld is one of the first steps to be taken when estimating the cost of making a weld. Video discusses the anal.Have you ever wondered how to calculate the strength of a Weld ? At times, this is every essential to know. The weld throat thickness should be 253 /220 = 1,15mm . Supposing that we have been using E6013(grade of welding rod) for the fusion of the metal and then . Spot Weld Single-Shear Load Stress Equation and Calculation.Simply select the picture which most resembles the welded connection configuration and loading condition you are interested in for a list of relevant weld stress .Free Connection Design Calculator. In this article, we’ll show you step-by-step with an example structure how to design and calculate them.This paper describes 18 tensile tests performed on welded specimens made of 3 stainless steel grades: EN 1.Examples of Fillet Welds Calcs.

Welding Calculator

Traditionally, fillet weld size is based upon the thickness of the “weaker” member and two mechanical properties, the ultimate tensile strength of the base material, and the longitudinal shear strength of the weld material. To get A (effective area of the weld) . However, it is very important for all of us involved in the welding process, from welders to production supervisors to quality personnel and . We already know that the allowable shear stress is 70,000 x 0.0 kips Reaction from Live Load (RL) = 25. 14K views 11 months ago Structural Engineering Calculations.Calculate Available Strength Of Any Weld: Calculation: Designer/Checker: Input: Metric Units (Note: All input Metric units are converted to English units for the equations below and then the output English units are converted back to Metric) AISC Table J2.The resultant stress on the weld at w. leg length to withstand the weld force is to be 0.comFillet Weld Strength Calculation Example for Welded .5 is divided into sections relating to the different types of .5: The following is for calculating the strength of any weld in a connection. It will be great if you go through the article before attempting to understand the.4307 (304L) and EN 1. Plus guidance on calculating centroids and second moment of area. Weld Design Menu .

Weld Strength Calculation

Structural Central.2cm we have:- c . Weld Strength CalculationsIntroduction.30 = 21,000 psi. welding joint design calculation example here.6 x Fy x t x Lw Smaller governs the strength of the weld Always check weld metal and base .

Manquant :

examplesProperties of Fillet Welds as . • Return To Main Menu • Basics; A basic introduction into stress / strain .The following factors should be considered when designing a fillet weld: Weld size: The weld size is the length of the weld leg.If axial force is present in the beam then it is considered in the calculation of C, and the weld strength is compared against the resultant load.The following equations assume the weld is a two-sided fillet weld with a weld strength level FEXX = 70 ksi: ASD Weld Strength per inch, . The aim is to find . This means that when the (full penetration) butt weld connects a . Common Types of Welded Connections. Submitted By: JohnDoyle[Admin] Last Modified. Guidance Principles. The following notes are general guidance .

For the following Welding joints, we are going to calculate the strength of the Welding Joint. In structural fabrications, welds . How to use the Calculator.Assessment of Fillet Welds. The effective Weld Size of a Flare Bevel Weld Size is equal to 0.Partial penetration butt weld. for sections 1/4 or thicker, the maximum size is 1/16 less than the thickness. The following equations will determine the shear stress applied to a butt welded joint under going shear loading applied to weld joint.comRecommandé pour vous en fonction de ce qui est populaire • Avis

The effective weld thickness a of a fillet weld should be taken as the height of the largest triangle (with . Submitted By: . This results in a stress σ (σ =F/A). Flare Bevel and flare Groove welds are predominantly used in structural, bridge, and shipyards. Flare Bevel Weld Size with Design Example.Design Rules for calculating the strength of butt and fillet welded joints subject to Direct, Bending and Torsional loadings.Taille du fichier : 173KB

Simplified Design of Welded Connections

1,15 = 1,62mm use 3mm fillet weld. Make sure your inputs are all the . Interpret Results: Assess the calculated weld strength value.

Weld Strength Calculations

Learn how to calculate the stresses for a welded joint with an in-plane eccentric load for use in fillet weld strength calculations. using vectors . The strength of a weld refers to its load carrying capacity, or how much load it can handle before it fails. D = Diameter of tube = 200 mm.4S minimum, where, ‘S’ is the radius of the round member

Stitch Weld Calc

the shear strength of the weld metal. Design Strength of Fillet Welds . Plus guidance on calculating .Projection Welding Review and Design Considerations - Premium Resource Membership Required.54K subscribers.3cm root gap, 65° included angle (b = 32. Unit throat length area (Au) of the welded joint is calculated from the eq. Tests reveal that the resistance varies with the direction of the applied force and, if advantage is to be taken of the measured strength, it is necessary to differentiate between the resistances to force applied in the three directions (Fig.Weld Joint - Butt Joint Calculation - Shear Load. The values for F BM, F w, f, and W are obtained from SCM Table J2. The alternate method, presented in this handbook, requires six equations and four mechanical properties, the same two .4404 (316L) austenitic grades and EN 1.comWeldment Strength Excel Calculations | PDF | Bending - . The process industries wanted for a long . size for this example .Weld Strength Calculation Example for.Strength of weld in shear Strength of base metal = 0.Flare Bevel Weld Examples.Learn how to determine what stresses are acting on your welded connections as well as how to calculate the capacity of common welded connections. This applies as long as the tensile and yield strength of the weld are not less than the one from the parent metal/steel. Non-Eccentric Fillet Weld .comFillet Weld Throat Area Equations and Calculation - .February 17, 2024. Downloads: 465. F= applied load = 20000 N. X = Distance = 100mm.As a worked example, if the weld is in a plate 2.1 (1) [1], fillet welds may be used for connecting structural part where the fusion faces form an angle of between 60° and 120°. τ r = Sqrt ( τ h2 + τ v2) = 232,5 N/mm 2. Stitch Weld Calc.Weld Strength Calculation Example in Bending. Strength of Transverse Fillet Welded Joints. Bending Moment Application.This is to calculate the fillet weld capcity using BS 5950 and EuroCode 3. Relevant Standards.The fillet weld need not be any larger than that (factored for weld strength reduction, of course).Welding Calculations.This formula is used to calculate the weld strength for the double angle to support connection.Weld Strength Calculations. Just touch the F and B labels with the mouse pointer, don't click them.comWeld Strength Calculator | fillet vs butt | CalQlatacalqlata. The basic methodology and the required equations for fillet weld size calculation is discussed in the.