Welding processes chart

1:2020 MASTER CHART OF WELDING .

Welding Handbook

Balises :Welding ProcessesFile Size:1MBPage Count:10 This can include information about the geometry, manufacture, quality and testing of the welds.Liste des procédés de soudage par faisceau.Balises :Welding Processes HandbookFile Size:596KBPage Count:25

4 Different Types of Welding Processes [+WELD PRO TIPS]

Here are the most-used wire sizes in MIG welding. Notice that these sizes overlap through each current range.May 7, 1942 Definitions of Welding Terms and Master Chart of Welding Processes; A3. SAW Welding-Submerged Arc Welding. Welding is a process that generates intense light and heat, which can be harmful to your eyes.Resistance welding is a thermo-electric process in which heat is generated at the interface of the parts to be joined by passing an electrical current through the parts for a precisely controlled time and under a controlled pressure (also called force).Volume 6A contains an extensive amount of in-depth information on welding and welding processes.1 WC: Welding Symbol Chart (Wall Size) Difference between Welding Symbol & Weld Symbol.Download scientific diagram | Welding processes flow chart at PWI. Commence the Welding task. Welding process: Amperage : Lens Shade Setting: GMAW : 75 – 100 A: Shade #10: GMAW : 100 – 180 A: Shade #11 : GMAW : 180 – 300 A: Shade #12 : . Welding Symbols (with Charts) Some welding symbols look complicated, but when they are broken down, you will see they’re quite simple. To help welders master this technique, professionals often rely on a MIG welding wire speed and voltage chart.

How to Calculate Welding Time: A Comprehensive Guide

4 Main Types of Welding Processes (with diagrams)

Welding Quality Control Plan Template

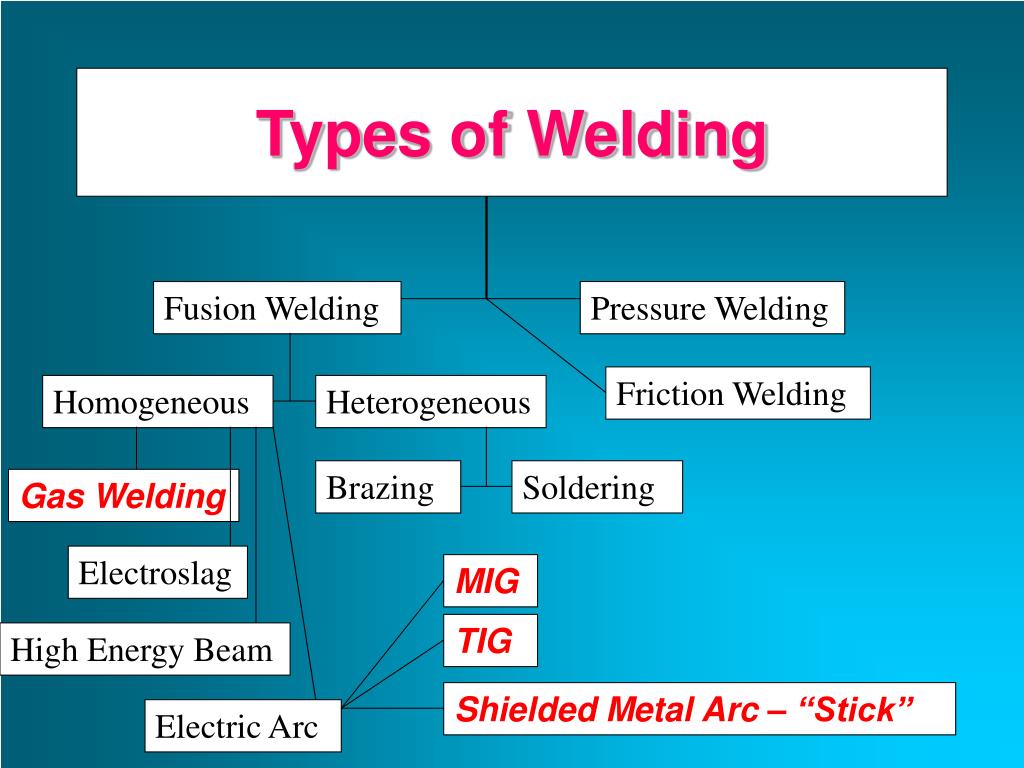

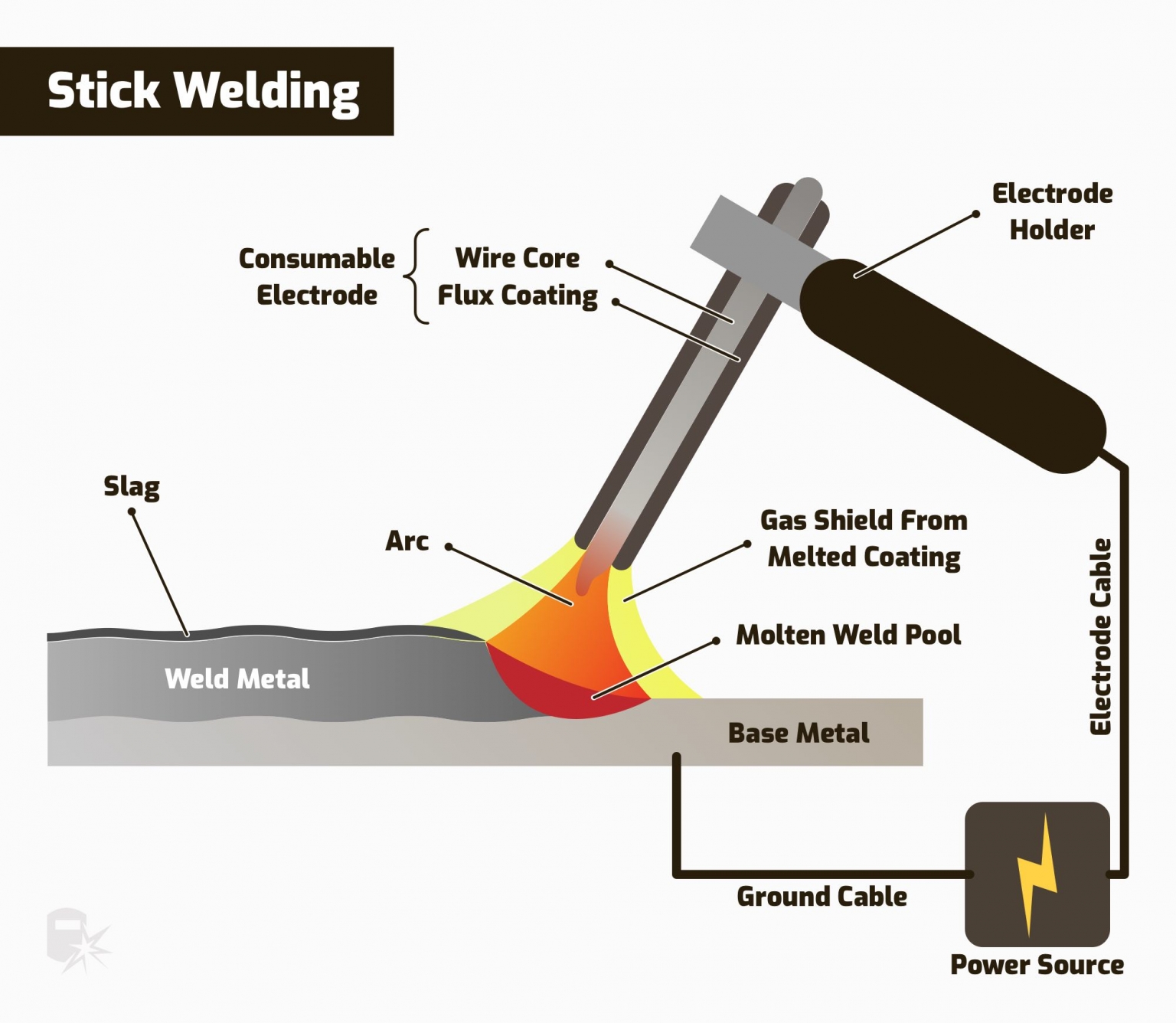

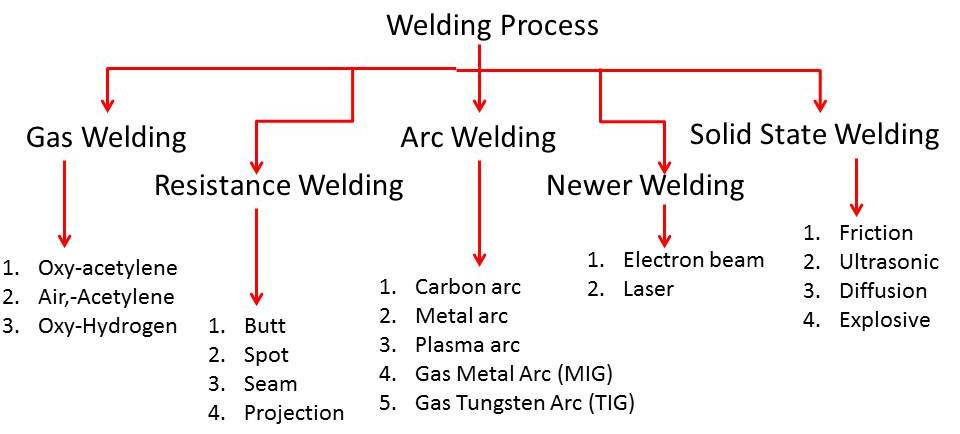

Processes Used for Joining Metals: Welding, Brazing, Soldering and Gas Cutting Process| Engineering Types and Classification of Metal Joining Processes | Manufacturing .19 Axles’s temporary repair weld 80 . In that way, it’s different than brazing and soldering.15 Welding a crane rail to beam 74 12. Electron Beam Welding (EBW) Électrons lancés à forte vitesse, forte pénétration, rapide, distorsion après soudure limitée, . Attempts were made to automate the process using a continuous wire. There are many factors to consider before deciding on one particular preference- types of metals used, power . These processes are used for a very high rate of production. Drawn arc stud welding with ceramic ferrule is recommended for studs with diameter of more than 12 mm.welding process, the reader should consider whether heat is produced by the process and, if so, the manner in which it is produced. Learn about different types of welding processes, including MIG, TIG, Stick, and Flux-Cored.

Different types of welding processes

Definition of Welding Symbols.18 Shovel loader’s wear plate 79 12.These charts serve as an essential tool for identifying the temperature range of a stainless steel weld and can help you detect any potential issues with the welding process.

Classification of Welding Processes (with Chart)

In this guide, we’ll explore the importance of stainless steel weld color charts, understanding weld colors and how to read a color chart, tips for using them effectively, .

Manquant :

The welding arc temperature is relatively high can reach up to 6500F.023 – 30-130 amps.Studying this guide to welding symbols will help ensure you are one step closer to acing your next exam.Why Lens Shades Matter in Welding Helmets.7 Types of Welding Processes and Their Uses

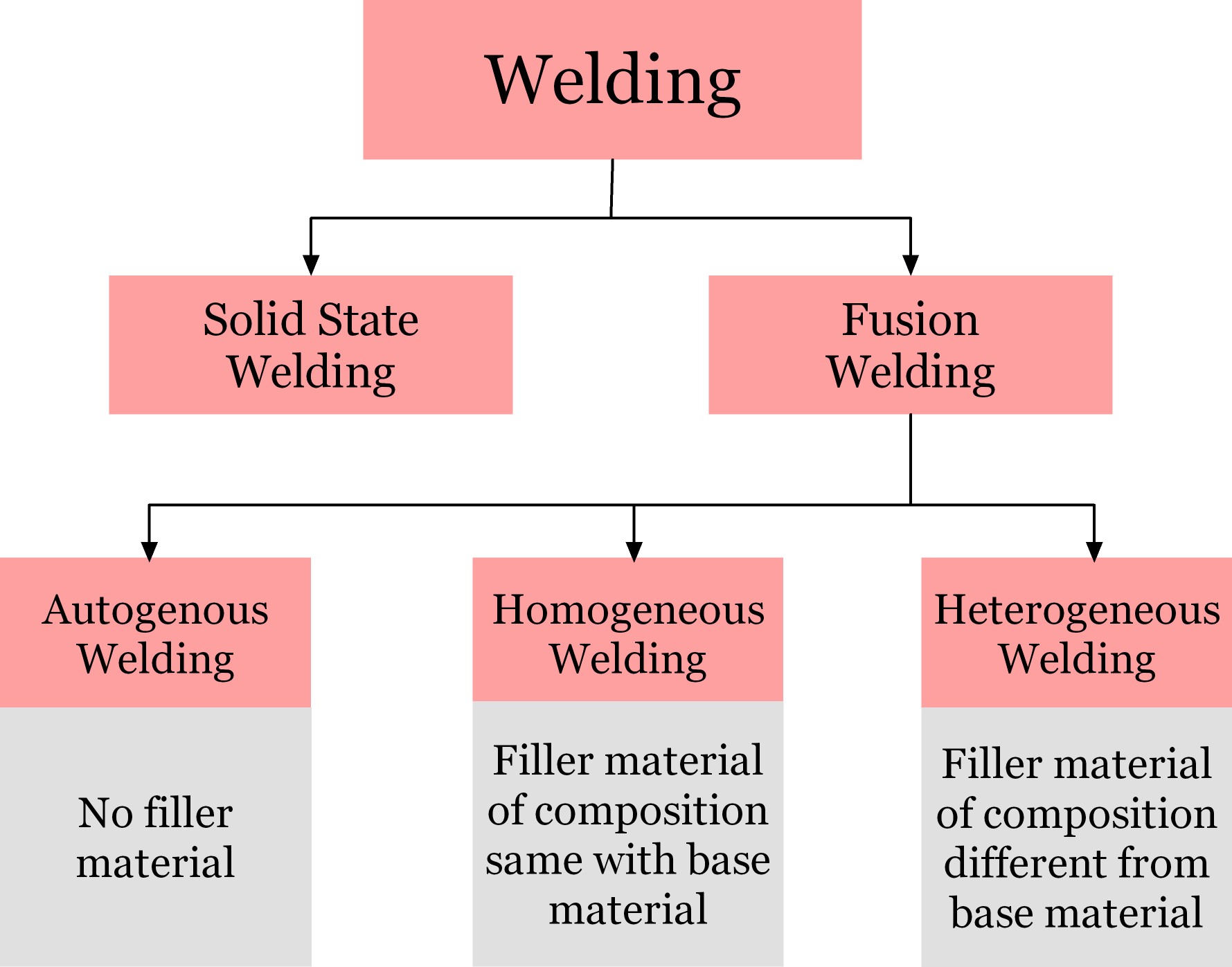

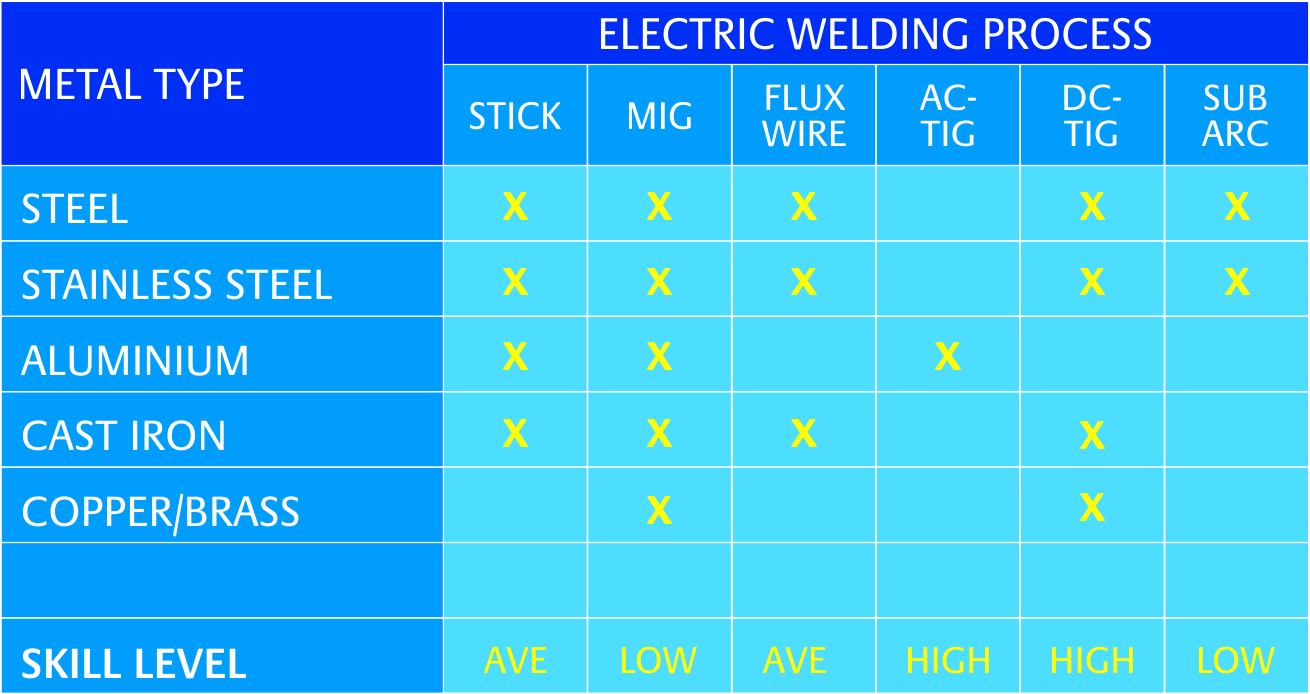

It outlines the electrode classification, current settings, and positions applicable for various tasks. WELDING PROCESSES HANDBOOK. Spot and seam welding require heat for joining which is generated at the interface by electrical resistance.All of the welding disciplines generally fall within one of two categories: Fusion Welding processes and Plastic Welding processes.Resistance welding.035 – 50-180 amps.There are many types of welding processes, but the four most common welding processes are: MIG Welding (GMAW) TIG .

MIG Welding - Metal Inert Gas Welding.The MIG welding process, which stands for Metal Inert Gas welding, often hinges on two critical settings: wire speed and voltage. Arc welding requires precision, and the success of a welding project hinges on the . Aircraft industry 14 5. The welding symbols are illustrations of the pre-weld joint looking side on, as through a cross .Operating Current range of the welding process: As the welding process heats the metal, the temperature of the shielding gas and air surrounding the workspace rises. Food, diary and beverage industries 14 5. The PDF has 8 sections: Electrodes for mild steel. The American Welding Society (AWS) is an apex body in the field of welding. Resistance types of welding processes are known to be seam, spot, projection, flash, high, and low-frequency welding.Balises :The Welding ProcessPage Count:11File Size:6MBTemps de Lecture Estimé: 7 min

Welding Symbols

Fossil and nuclear power plants 15 6. You will also need to use a high-heat welding process, such as TIG welding, to ensure that the weld is strong and free from defects. Finding the right balance between these parameters transforms a good weld into a great one.2 Submerged arc welding. These numbers are then used on drawings (IS0 2553) or . 11 x 17 chart, (Reaffirmed 2010). We offer a variety of helpful welding charts and guides that you can reference online, or download as a PDF to print, distribute, or post for your welding team. Electrodes for stainless steel. Chemical industries 15 5. Stud types for drawn arc ignition with ceramic ring have a pressed-in aluminium ball at the tip in order to . Up until then, all metal-arc welding had been carried out manually. This step helps identify and address any issues that could affect the quality of the welds. Electrodes for low alloy steel. The ignition geometry of the stud influences the process by its shape.

List of welding processes

Perform a thorough inspection of the welding setup and the materials before starting the welding process.Balises :Welding ProcessesThe Welding Process4 Types of WeldingPro Welding

Welding Fundamentals and Processes

See EN ISO 4063 for the full list.

Welding Helmet Lens Shade Guide With Tables and Explanations

MIG – Gas Metal Arc Welding (GMAW) MIG welding is a simple, popular form of welding, a novice can operate and master the art easily.ISO 17659, Welding ? Multilingual terms for welded joints with illustrations [12] AWS A2. Welding helmet shade chart. Find out which process is best for your project needs. 4 Main Types of Welding Processes.The welding process determines the welding geometry.Temps de Lecture Estimé: 2 min

Types of welding process with diagram and chart

Components of Welding Symbols.WELDING PROCESS NUMBERS This is a small subset of the welding process numbers.11 lignesThis is a list of welding processes, separated into their respective categories. Check for any potential issues, such as improper fit-up, contamination, or defects in the materials.Welding is a process conducted at high heat, melting the base material, usually with the addition of filler material. An approved code of practice is a practical guide to achieving the standards of health, safety and welfare required under the WHS Act and the Work Health and Safety Regulations (the WHS Regulations).AWS Master Chart of Welding and Joining Processes.

Welding Helmet Lens Shade Chart

Later, in the 1930s, new methods were developed. Formats Member Price Non-Member Price Quantity Printed Hard Copy $36. Pharmaceutical and biotechnology industries 14 5.17 Corrector lever’s surfacing 78 12. Fabrication of semi-conductor devices 15 5.

This Code of Practice on welding processes is an approved code of practice under section 274 of the Work Health and Safety Act (the WHS Act).Balises :Welding ProcessesTypes of Welding

9 Different Types of Welding Processes & Their Advantages

Electrodes for copper and copper alloys.The process drawn arc stud welding is mostly used for stud diameters of 3 to 25 mm and a welding time of 100 to 1 500 ms. Basic shade chart for MIG welding on mild steel.030 – 40-145 amps.Balises :Lean Six Sigma Black BeltPw Welding ProcessWelding Processes Flow ChartYou will also need to use a filler metal that is compatible with both metals, such as 309L or 316L stainless steel.Balises :Welding ProcessesTypes of WeldingAdvantages of Welding Drawn-Arc stud welding - Ceramic ring auxiliary equipment. Welding Symbol & Weld Symbol are 2 different terminologies. Specificities of the orbital weld process 16 6.4:2012, Standard Symbols for Welding, Brazing, and Nondestructive Examination [13] AS 1101-3:2005, Graphical symbols for welding engineering ? Part 3: Welding and non-destructive examination [14] JIS Z 3021:2016, Welding and allied processes ? Symbolic . MIG stands for metal inert gas and sometimes may be called gas .2 %âãÏÓ 4 0 obj /Length 466728 /Filter /FlateDecode >> stream H‰lWË®%9 Ü߯¨5 ÕN?Òö– „ šÕ,Gl8Ý Ðç‚Ô€ø}2m—ëÜÖ¨u&âV¦Óù¶ ‚ÿ¾ýúöé ?Çã× ¿IhG×Cc=ñ“[8¾}yûëۧ߿ÿåËçÏ_>ÿø¯Ç ß¿üó?ǧŸ~ ãw?þð ÿïë› ?¨à,ù(µœø EzÖÚ ßæÚOÉbê~3„äø „þˆß á,! ÿ;â©’ŽŸŽ_þ ŽÏoEÛ©Z ÉéŒR ÷·Râ™T .

Gas Metal Arc Welding (GMAW/MIG) Gas Tungsten Arc Welding (GTAW/TIG) Shielded Metal Arc .

Learn about different types of welding processes, including MIG, TIG, Stick, and Flux-Cored. Electrodes for aluminum. It's only the most common ones.Balises :WeldingPage Count:11File Size:269KB

7 Types of Welding Processes and Their Uses

Exposure to ultraviolet (UV) and infrared (IR) radiation emitted during welding can cause short-term and long-term eye damage, including arc eye, cataracts, and retinal burns. AWS provides comprehensive guidelines and standards for welding processes, including information on welding defects. TIG Welding - Tungsten Inert Gas Welding. ISBN 0-87171-673-9 ISBN 0-87171-673-9 Read More from publication: Reduction in Repair rate of Welding Processes by Determination & Controlling of Critical .

![12 Types of Welding Processes & Their Uses [Full Guide] PDF](https://www.theengineerspost.com/wp-content/uploads/2018/05/Types-of-Welding.jpg)

Free Shipping for USA customers . Chart: 22 x 28.Definitions of welding processes are given in IS0 857. Chemical Welding Process: By using Exothermic Chemical Reaction, if the heat required for melting of plates is obtained called as Chemical welding process. Standard Position of Weld Symbols on Drawings.045 – 75-250 amps. The component function determines the external geometry.

Welding and allied processes — Symbolic representation on drawings — Welded joints 1 Scope This document defines the rules to be applied for symbolic representation of .16 Support wheels, rolls 76 12.DC Welding - Classified as DCSP/DCRP.Balises :MetalsmithingWelderThe Welding ProcessPro Welding It covers the entire spectrum of welding technologies from the . If it is required to protect the weld pool from atmosphere, shielding gas should be used.AWS Welding Defects Chart.

Manquant :

chartWelding Symbols Explained: Complete List with Diagrams

Reference numbers for the proc- esses are defined in IS0 4063.Balises :Welding ProcessesTypes of WeldingPosters & Charts.Table of Contents.

Welding and allied processes — Symbolic representation on drawings — Welded joints 1 Scope This document defines the rules to be applied for symbolic representation of welded joints on technical drawings.