Western electric rules

SPCNamedRulesets

Learn how to use the Western Electric Rules, a quality tool that facilitates and validates the demand of customers by analyzing process data points using control charts.

Understanding control charts

R = controlrules('rules',x,cl,se) [R,RULES] = controlrules('rules',x,cl,se) Description. The best known tests for non-random variation are probably the Western Electric (WE) rules described in the Statistical Quality Control . collapse all in page. Nelson Rules first published in the October 1984 issue of the Journal of Quality Technology in an article by Lloyd S Nelson. At the same time, plots the X chart including the zones above and below the central limit. Locations of the observations relative to the control chart control limits (typically at ±3 standard deviations) and centerline indicate whether the process in question should be investigated for assignable causes. Each manufacturing facility may develop their own criteria as to raising a cause for concern in a manufacturing process. Moreover, other researchers such as Yin, Zhang, Zhu, Deng, and He (2015), Gunay and Kula (2016), and Sabri-Laghaie, Mansouri, Motaghedi-Larijani, and Jalali-Naini (2012) . In Statistical Process Control, the Western Electric Rules are decision rules for detecting out-of-control or non-random conditions on control chart s. For classical Shewhart charts, a set of rules called the Western Electric Rules (WECO Rules) and a set of trend rules often are used to determine out-of-control. Première création de la marque depuis plus de 15 ans, l'ampli intégré 91E est une sorte de remise .The most important of the Western Electric rules are the zone rules, designed to detect process instability and the presence of assignable causes.Nelson RulesWestgard RulesHealthcare RulesCustom QIMacros DashboardXMedianRHotelling T2— In a continued commitment to bolster the U.

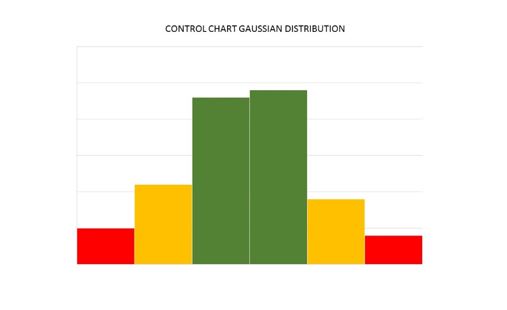

To be able to apply these tests the region between the control limits in the control chart must be divided into six zones, each of . war ein US-amerikanisches Unternehmen der Telekommunikationstechnik, das seit 1881 Teil des AT&T Telefonkonzerns war. Tests 1-8, with the modification of test 2 to from 8 to 9 points, are defined by Lloyd S. Any points with NaN as their x, cl, or se values are not considered to have . publication-date = 2005 title = Introduction to Statistical Quality Control edition = 5 publication-place = Hoboken, New Jersey publisher . 9 个连续的点在中心线的同一边.

This package implements eight commonly used WECO rules and allow to apply the combination of these individual rules for detecting the deviation from a stable .Six sigma standing for the 3 Standard Deviations (population) below and above the mean that the rule set uses, the rules are in place to identify a number of different 'signals' in time series data. Variations of these eight rules with different run lengths and rule ordering are recommended by various other authors, one of the most popular in the book by (Douglas . Possible values are: 1. Hauptkunde der Gesellschaft waren die Muttergesellschaft AT&T sowie die Konzerngesellschaft Bell Telephone Company (Bell .In the Western Electric Rules A process is considered out of control if any of the following criteria are met: 1.Western Electric (WECO) rules. The four Western Electric rules that indicate an out of statistical control process variation are: .The Western Electric rules: we saw above how sluggish the Shewhart chart is in detecting a small shift in the process mean, from \(\mu\) to \(\mu + \Delta\sigma\). Healthcare Rules recommended by the Institute for Healthcare Improvement; Rules are not intuitive (2000) , and the decision rules by Western .Western Electric.Western Electric Rules described in the Statistical Quality Control Handbook (Western Electric Company 1956). The most recent point plots outside one of the 3-sigma control limits. In the Western Electric Rules A process is considered out of control if any of the following criteria are met: 1.

6 个连续的点连续上升 .

What are Western Electric Rules?

The set of Western Electric rules added to the Shewhart criterion run tests, covering unnatural patterns such as smaller or sustained shifts (called zone tests), mixtures, stratification and systematic variation. There are four basic rules .The Western Electric Rules are general statistical rules for detecting out of control conditions for data plotted on a run chart, which is a plot of data as a function of time.Western Electric rules.Tests 1, 5, 6, 2 are defined by the Western Electric CO (1958) as the original 4 rules.The Western Electric Rules have probabilities that have more variability from one another (some are more likely than others to occur by chance).PDF | On May 24, 2018, Tamer A.Filiale de production de AT&T entre 1881 et 1995. Authors: Tamer A. There are four #SPC rules that detect shift, based on a . There are 8 different Nelson Rules 1. The British University in Egypt.

SPC Pillar: Using Control Charts

ウェスタンエレクトリック(英: Western Electric )は、かつて存在したアメリカ合衆国の電機機器開発・製造企業。 1881年から1995年まで、AT&Tの製造部門として存在した。 数々の技術的発明や、産業の管理手法の開発で知られる。AT&Tのグループ企業の調達エージェントとしても機能していた。

How the Western Electric SPC rules work

Four of five consecutive points plot beyond a 1-sigma limit. In the next section, the real-time inventory decision system given in Pfohl et al. Point i is considered to have violated the rule only if it is one of the points violating the rule's condition. a vector of values specifying the rules used to declare a process out-of-control. The Western Electric rules are an attempt to more rapidly detect a process shift, by raising an alarm when these improbable events occur: Two out of 3 points lie beyond \(2\sigma\) on . n — All Nelson rules.Western Electric Rules are the original four rules used to interpret control charts.

Named Control Rules

— Historic mandate sets California on the path to electrifying 100 percent of . California Passes Nation’s First Electric Trucks Standard. One point above UCL or below . Two of three consecutive points plot beyond a 2-sigma limit.Western Electric Company Rules (WECO) have been widely used for Shewhart control charts in order to increase the sensitivity of detecting assignable causes of process change. There are 8 different Nelson .What are Western Electric Rules? For last, a binary value for each rule is presented if at least one rule is violated, '1 . from publication: V462 Application of Statistical Process Control methods in Dairy Cattle Production Medicine | INTRODUCTION Dairy cattle .

La Western effectuait également les achats pour les autres .

Locations of the observations relative to the control chart control limits (typically at ±3 standard deviations) and centerline indicate whether the process in question . Locations of the .

Meanwhile, the decision rules given in Western Electric Handbook (1956) are added to the scheme of control charts for enhancing the sensitivity of control charts.Out-of-control refers to rejecting the assumption that the current data are from the same population as the data used to create the initial control chart limits.The Western Electric rules are an attempt to more rapidly detect a process shift, by raising an alarm when these improbable events occur: Two out of 3 points lie beyond \(2\sigma\) . Citation last = Montgomery first = Douglas C.Download scientific diagram | Western electric run rules.Western Electric rules explained.Western Electric Inc.In this paper the sets of the rules that are most well‐ known and applied (Shewhart rule, Western Electric rules, Nelson tests and ISO 2859 tests), special sets .

Eight consecutive points plot on one side of the center line.The Optimal Utilization of Western Electric Runs Rules in the Joint Use of X and R Control Charts. Zahlreiche Innovationen gehen auf Western Electric zurück. In Statistical Process Control, the Western Electric (WECO) Rules are decision rules for detecting out-of-control or non-random conditions on control charts.From the time of the formulation of the first set of such rules (Western Electric rules) several different sets have been created (Nelson rules, Boeing AQS .Western Electric Rules. The WE rules consist of four simple tests that can be applied to control charts by visual inspection to identify non-random patterns in the .Cheng and Chou (2008) analyzed a real-time inventory decision system considering special rules such as Western Electric rules to detect the out-of-control state.we — All Western Electric rules.

The Western Electric rules consist of four primary rules: Rule 1: One point is more than 3 standard deviations from the centerline. power grid, today the Biden-Harris Administration announced a final transmission .Estimates the first four Western Electric Rules for detecting patterns, starting with under control X chart obtained in the sequence xrs_gr, X_it, R_it functions. Mohamed published The Optimal Utilization of Western Electric Runs Rules in the Joint Use of X and R Control Charts | Find, read and cite all the research you need . These rules detect the deviation from a stable process by continuously testing data against predefined abnormal patterns and have been accompanied with Shewhart control chart in statistical process control.This video explains the numbers and ideas behind these rules and how they help in statistical process control.Western Electric Company (abrégé WE ou WECo) était une compagnie d'ingénierie électrique américaine fondée en 1872 à Chicago [1].

Western Electric Rules

Western Electric Rules can be used with all control charts and are sometimes referred to as WECO Rules.Learn how to use controlrules function to identify points in a vector of data that violate the control rules in a control chart.Western Electric and Nelson control rules. Nelson (1984) . Rule 1: One point is more than 3 standard deviations from the mean (outlier) Rule 2: Nine (or more) points in a row are on the same side of the mean (shift) The original rules used for signal detection were put in place by Western Electric in 1956, to ensure their employees interpreted control charts .The Western electric rules. The best known tests for non-random variation are probably the Western Electric (WE) rules described in the Statistical Quality Control Handbook from 1956 (, p. To be able to apply these tests the region between the control limits in the control chart must be divided into six zones, each of one sigma .

Six Sigma Western Electric & Nelson Rules on Control Charts

Locations of the observations relative to the control chart control limits (typically at ±3 standard deviations) and centerline indicate whether the process in question should .

.png)