What is a petroleum refinery

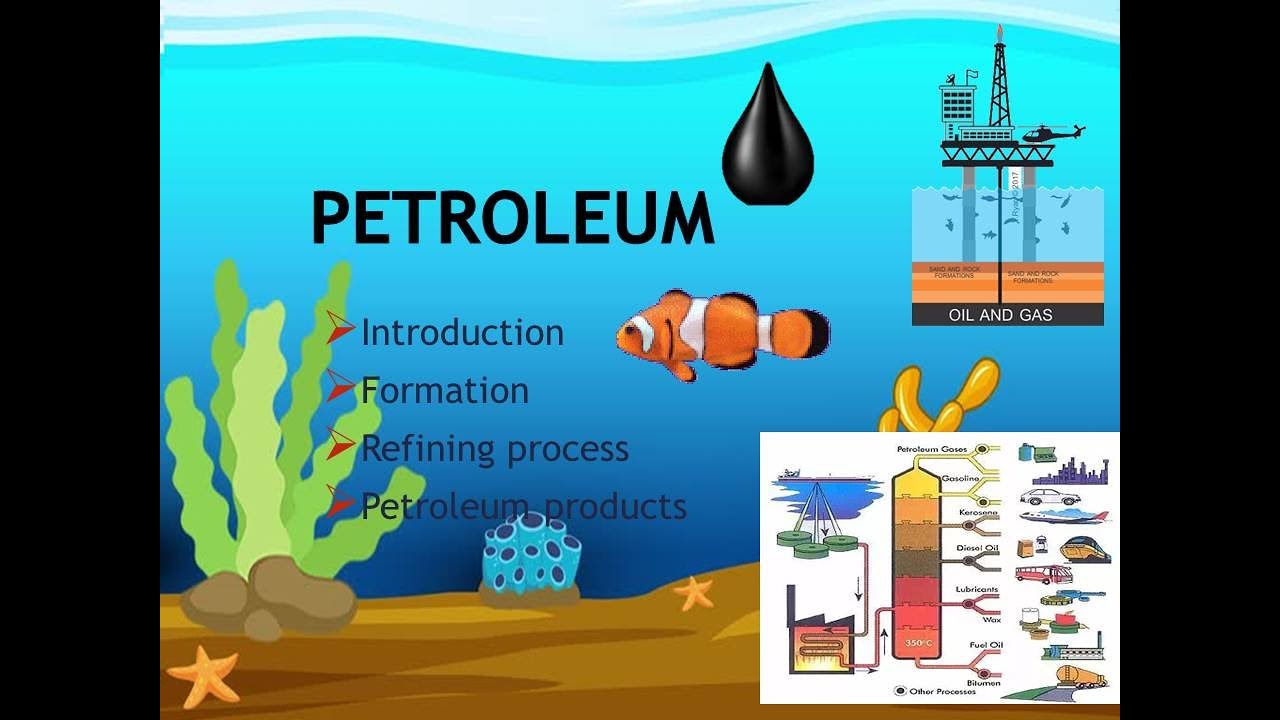

Fluid Catalytic Cracking (FCC) is the conversion process used in a petroleum oil refinery to convert the low-value heavier long-chain hydrocarbon refinery fractions such as heavy vacuum gas oils into greater economic value lighter products, mainly gasoline, distillate, and LPG.The first part (section “ Refinery Operation Planning ”) deals with the planning of a refinery’s operation, which includes its optimized crude runs, product slate, . Learn more about petroleum refining, including its history and the various processes used .Dangote refinery is a 650,000 barrels per day (bpd) integrated refinery and petrochemical project under construction in the Lekki Free Zone near Lagos, Nigeria.Types of refineries. Petroleum products and their uses.Today, Bharat Petroleum operates several oil refineries in India.A petroleum refinery is a collection of unit operations, such as fractionation towers, pumps, and heat exchangers. Activists closed lobbied to close it.A coker takes the lowest value bottoms material (vacuum resid) and cracks it to the point that all of the resid is eliminated, yielding only lighter fractions and solid carbon (). A new 9 MMTPA Greenfield Refinery-cum-Petrochemical complex is being set .edu(PDF) FUNDAMENTALS OF PETROLEUM REFINING - . It is expected to be Africa’s biggest oil refinery and the . The primary product of the reformer is reformate. Petroleum products are the outputs of a petroleum refinery. A corn kernel is smaller and .” It is derived from the Greek word “petra” and the Latin word “oleum”.

Process units

A petroleum refinery is a set of installations intended to transform crude oil, generally unusable as such, into petroleum products: motor gasoline, jet fuel, diesel . - Good team working as well as the ability to work independently. It’s unclear what will replace it.Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene.With momentum building in the renewable fuels space, the petroleum industry is looking to convert existing refineries to produce renewable diesel (RD) and .A typical refinery produces a wide variety of different products from every barrel of crude oil that it processes.Refined products. A petroleum refinery is a processing plant that converts crude oil into a mix of different finished petroleum products.99% equity stake in the JV company, HPCL-Mittal Energy Limited (HMEL), which operates an 11. Home Technology Industry.

Petroleum refining processes

Most of a refiner's margin comes from the higher-value light products (i. Each of these plays a role in the overall process of converting crude oil into finished petroleum .Petroleum, also known as crude oil or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations.Petroleum refineries are complex and expensive industrial facilities. Off-sites consist of tankage, flare systems, .A typical fluid catalytic cracking unit in a petroleum refinery. It is classified by density, sulfur content and acidity, and those factors determine how the oil is refined. Petroleum Meaning. Routes to renewable fuels.3 MMTPA capacity Refinery at Bhatinda in Punjab.

Refinery utilization rates and environmental .

Announcing the commencement in a statement, the company said the .Petroleum, called crude oil in the industry, is a fossil fuel found in underground reservoirs.The major contribution from the coker is that it allows .HANDBOOK OF PETROLEUM REFINING PROCESSES .

Oil and petroleum products explained

Also known as: platformer, hydroskimmer, CRU, CCR, SCR, powerformer, ultraformer, magnaformer, rhenifomer.

Diesel

The profitability of a refinery comes from the difference in value between the crude oil that it processes and the petroleum products that it produces.Petroleum refineries convert crude oil and other liquids into many petroleum products that people use every day.

Oil Refinery in India

The amount of individual products produced varies from .Conventional petroleum refineries can be modified to process bio-basestocks into renewable fuels.How an Oil Refinery Works.

Oil and petroleum products explained Refining crude oil

Analysis and design of these units require knowledge of the thermodynamic and physical properties of the petroleum fluids.The skills that are important for refinery work include but are not limited to; - Mathematical and scientific skills. Naphtha is a general term as each refinery produces its own naphthas with their own unique initial and final boiling points and other physical and compositional characteristics. Inputs & outputs.

Reformer

Recent market .HPCL holds a 48. The rapid cracking reactions of the FCC unit depend upon the .This chapter provides an introduction to petroleum refining. Ever wondered how an oil refinery works? Now you can learn more about the technology involved in refining crude oil into the thousands of . A biorefinery concept could be built on three main initial

platforms to promote different product slates (see Figure 1). refineries because of refinery processing gain.

Crude oil comes out of . It is mainly used as paving material, road building, paint, water-proofing agent, etc. Diesel is one of the higher-valued light products (along with jet fuel and gasoline ). The refining process. refineries produce, from a 42-gallon barrel of crude oil: About 19 to 20 gallons of motor gasoline. It discusses different refining processes and refinery configuration, which can range from single topping for crude .comAN INTRODUCTION TO PETROLEUM REFINING AND THE .

Refined products

Petroleum, also known as crude oil or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, [1] and is found in geological formations.

Dangote Refinery, Lagos, Nigeria

Mumbai Refinery As one of the most versatile oil refineries in India, the Mumbai Refinery excels in all aspects of quality, technology, fuel & loss, human relations, safety, environmental friendliness and operating costs. Different types of refineries are as follows: Petroleum oil refinery, which converts crude oil into high-octane motor spirit (gasoline/petrol), diesel oil, liquefied . Oil refining is a process by which crude oil is processed and transformed into usable petroleum products such as gasoline, diesel and other heating oils. Petroleum refineries are one of the most vital continuous-flow manufacturing facilities of the petrochemical industry [1].

Petroleum Refining

Isobutanes combine with Olefins (C3 ~C5) in the presence of strong acids to produce longer-branched chain . Alkylation is a chemical process in a petroleum oil refinery in which a high-quality gasoline component (alkylate) is produced by the reaction of low-value light hydrocarbons of the LPG range i.Philadelphia Energy Solutions was the largest oil refining complex on the East Coast.Refining Petroleum Refining petroleum is the process of converting crude oil or bitumen into more useful products, such as fuel or asphalt.Also known as: petroleum products, oil products, finished products. The thick gooey substance extracted from the ground as unprocessed oil needs to be processed before different grades of oil can be extracted and used as fuels.They heat the crude oil flowrate up to a temperature of 390–400 °C before being sent to the atmospheric distillation columns [3]. This chapter is divided more or less into three parts. This increase in volume is similar to what happens to popcorn when it is popped.Oil Refining - an overview | ScienceDirect Topicssciencedirect.

Fluid Catalytic Cracking (FCC) in Petroleum Refining

- Good attention to detail and focus.

Overview

API

Also known as: delayed coker, DCU. The name petroleum covers both naturally occurring unprocessed crude oil and petroleum products that consist of refined crude oil. It also owns a 16. The word petroleum translates to “rock oil.Frequently Asked Questions–FAQs. In a refinery, the coker is the most extreme of the bottoms upgrading process units.The meaning of REFINERY is a building and equipment for refining or processing something (such as oil or sugar).

Refinery Definition & Meaning

Some of their key industrial units are the heating furnaces [2]. More than a dozen other petroleum products are also produced in refineries, including liquids the petrochemical industry uses . All refineries have three basic steps: Separation.Oil refinery workers, including management positions, make over $190,000 per year on average, compared to $84,500 for all private sector jobs in California. Generally, refineries operate to make as much of the high-value light products (gasoline, jet fuel, . A corn kernel is smaller and more dense than a popped kernel. How to use refinery in a sentence. 3 to 4 gallons of jet fuel. 11 to 13 gallons of distillate fuel, most of which is sold as diesel fuel. Diesel is one of the major petroleum products produced from processing crude oil in a petroleum refinery. The purpose of the reformer is to upgrade heavy naphtha into a high-value gasoline blend stock by raising its octane. Refinery rankings.

Fluid Catalytic Cracking Process in Oil Refinery

Every barrel of crude oil can be turned into several products: 8% refinery gases and light products like propane or butane; 49% gasoline It is used primarily in the transportation sector, and it is the primary fuel used in heavy-duty trucks and locomotives. Gaseous refinery . Before this process can be carried out, petroleum/natural gasses in its crude state need to be drilled out of the earth crust using highly sophisticated machinery.An oil refinery is a facility that takes crude oil and distills it into various useful petroleum products such as gasoline, kerosene, or jet fuel. Naphthas may also be produced from other material such . However, it also generates large amounts of hydrogen that can .Refinery Economics. A typical refinery produces a wide variety of . The cracking of petroleum hydrocarbons . Fluid catalytic cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum (crude oils) into gasoline, alkene gases, and other petroleum products.orgLinkedIn: https://www. Under the terms of the joint venture, Eni was responsible for the management of the .eduRecommandé pour vous en fonction de ce qui est populaire • Avis

Petroleum refining

42-gallon barrel of crude oil yields about 45 gallons of petroleum products in U. Also known as: petroleum products, oil products, finished products.