What is an a3 in lean

A3 is the size of paper, based on international standards.

A Deep Dive into the A3 Problem-Solving Approach

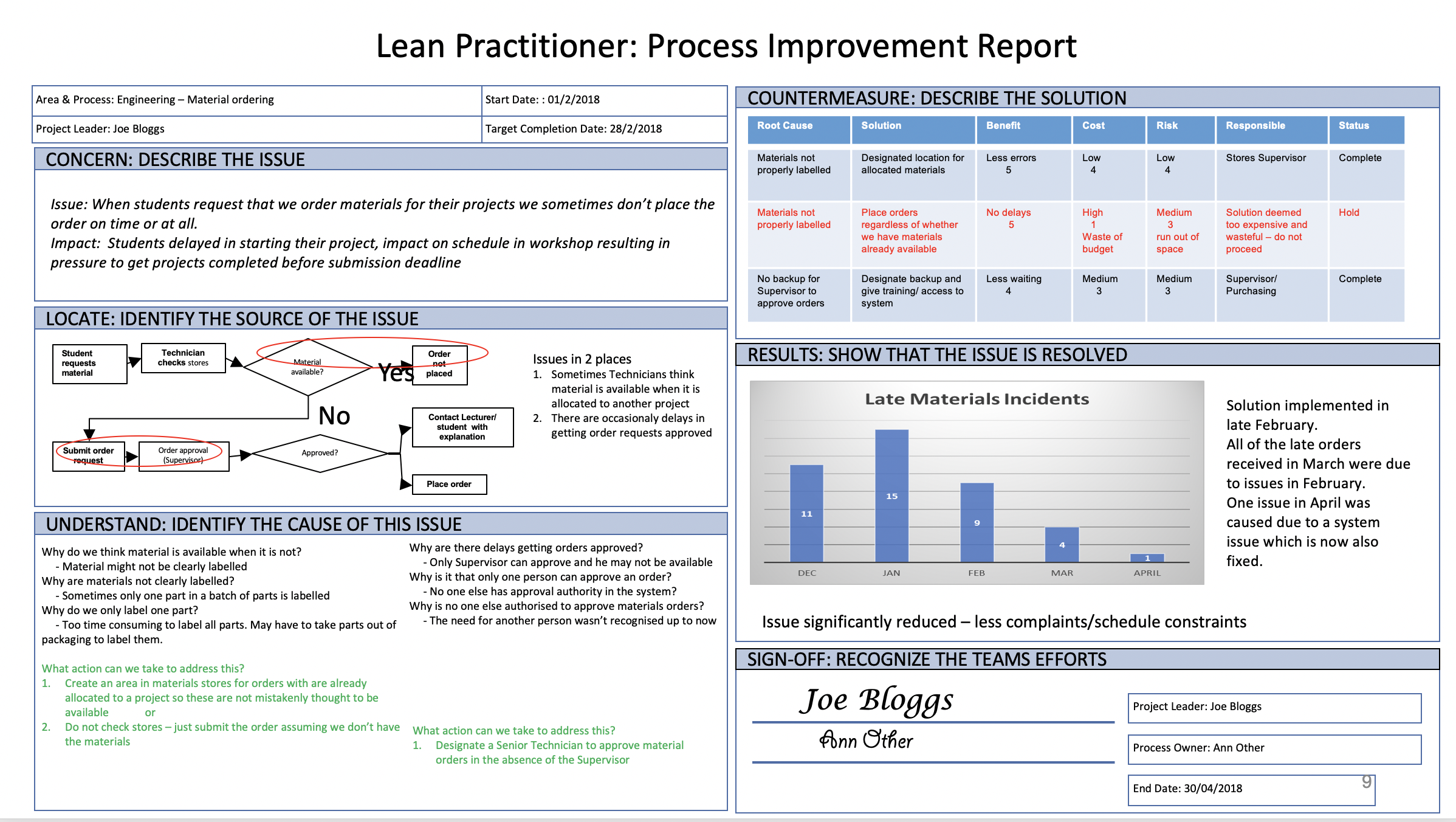

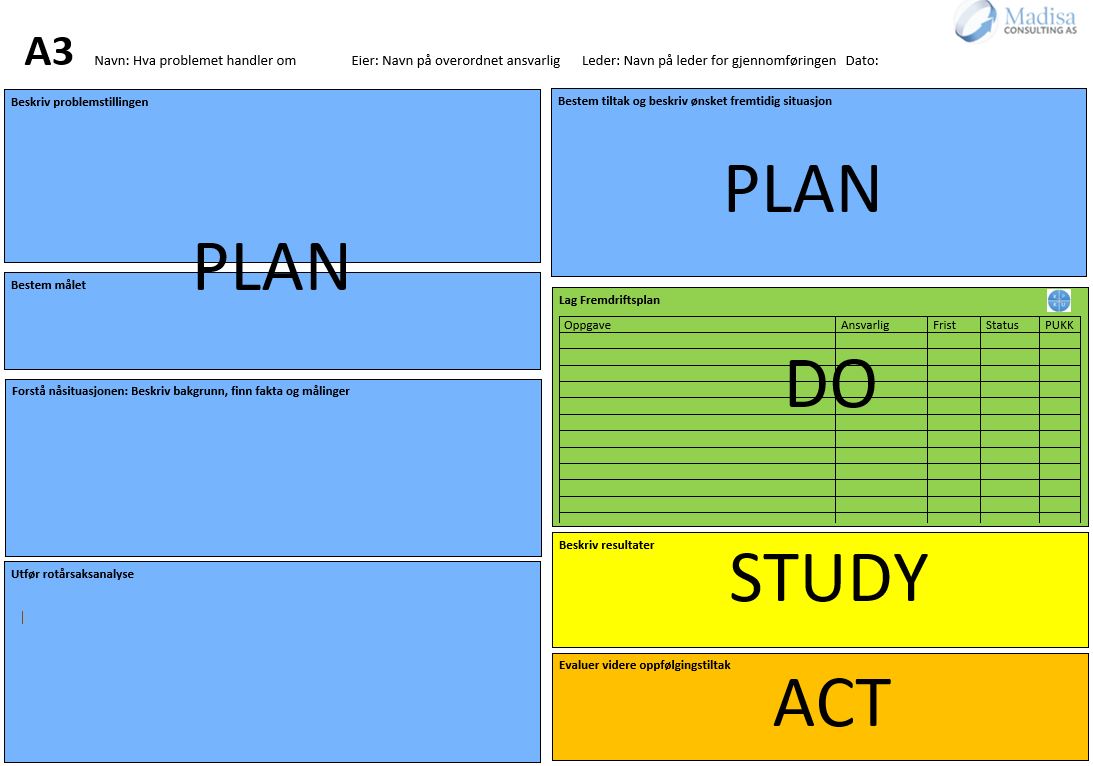

It is always real time. Why to Use A3 A3 is a step-by-step approach for applying plan-do-check-act, also known as PDCA or the Deming cycle. In order to do this effectively, the entire organization should .A3 reports for lean construction management can bring a range of advantages, such as improving project performance and customer satisfaction, increasing team collaboration and alignment, fostering .

Chapter 1 What Is an A3?

Le rapport A3 est l’un des outils affiliés à la méthodologie du Lean Management. When used during problem solving activity, it should be used while .A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at Toyota and typically used by lean manufacturing . Deze LEAN methode kan in bijna elke probleemsituatie worden toegepast, mits de tien stappen in het proces worden doorlopen: Stap 0.The Lean Lexicon, Fifth Edition defines the “A3 Report” as “a Toyota-pioneered practice of getting the problem, the analysis, the corrective actions, and the action plan summarized on a single sheet of large (A3) paper, often using graphics. A3 thinking is the process by which Toyota identifies, frames, and then .A3 - A Lean Approach to Problem Solving. Within Toyota and other lean companies, the term means much more.

The A3 approach wants to fit ‘everything’ on one sheet of paper and make it as concise and as visual, and obvious as possible.The DMAIC problem-solving method may seem like a stranger to the A3 but they actually make a great pair. Otherwise, A3 Problem Solving will just join the .

A3 Process and Problem Solving

A3 is a structured and very useful problem-solving template.Step 1: Describe the process issue and its impact. WHAT IS A3? It stimulates learning, forces us to focus on what is a priority, and supports both mentoring and leadership.A3 Thinking for Powerful PDCA to Improve Project Delivery. It also requires a face to face . Toyota’s insight many years ago was that every issue an organization faces can and should be captured on a single sheet of paper. In Toyota culture, problems are solved on the factory floor, or Gemba.Lean Enterprise Academy - Example of learning to use the . But first, a bit of background.A3 reports have become one of the most popular lean tools today, a way for people and teams to work together to solve problems; and their widespread adoption could easily be viewed in lean terms as. The A3 Report format allows the entire problem identification, clarification, analysis and resolution steps to be .

An Intorduction to the A3 Lean Thinking Tool

Don’t mistake A3s as a .

What is an A3 Report?

A3 Problem solving is a structured and systematic approach to problem-solving that originated with the lean manufacturing methodology.

How to put your Lean training to use using an A3 template

A3 problem solving

The techniques and activities differ .

2) it is performance based.

How to Start the A3 Problem-Solving Process

This Japanese word means “real place” and can be any place where work is carried out and value is generated. When we are very close to a problem it is sometimes easier to describe the solution we think we need than the problem we are trying to address.A3 - Une approche Lean de résolution de problèmes.Q: How does A3 problem solving differ from other problem-solving methods?A: A3 problem solving emphasizes a systematic and structured approach, focusing on problem understanding, root cause analysis, and the development. Inspirée du système de production de la marque Toyota, celle-ci organise le travail de façon à . PS: Get the A3 Report Template Download for Free. Traducteur: Loïc de Terwangne. The structure of the A3 report is based on the PDCA cycle and visual management, and although there are variations, in most industries it consists of the following basic parts: 1.

How A3 Reports Boost Lean Construction Management

The A3 report is a powerful Lean Six Sigma tool that helps you document and communicate the problem-solving process in a concise and visual way. The form is used as a guide for many project teams to find answers, and then the team arrives at . Being a leader of lean thinking and practice requires an in-depth understanding of the process and a passion for guiding others.Q: What is A3 problem solving?A: A3 problem solving is a structured approach used to tackle complex problems and find effective solutions.Methodology Six Sigma Terms.The challenge with the A3 process isn’t in learning to write an A3 report; it’s in understanding how to use it as a managerial process.The A3 method is based on the Toyota production system, also known as Lean Manufacturing.Also known as A3 Problem Solving. The system focuses on reducing waste and continuous improvement. For another, the foundation of both come from Deming.Using a very simple approach, A3 problem solving is composed of the following seven steps shown below. It is based on the Plan-Do-Check-Act (PDCA) cycle .Q: What are the key benefits of using A3 problem solving?A: A3 problem solving provides several benefits, including improved communication, enhanced teamwork, better problem understanding, increased probl. How to use lean in a sentence.Three Steps to Applying the A3 Problem-Solving .orgThe 8 Steps of A3 Problem-Solving Method - Olanabolanabconsults. It consists of a comprehensive template which can be used to . Voorbeeld: Structureel te late . A significant part of a leader’s role involves addressing problems as they arise. PDCA is a Lean technique that has proven effective in driving productivity and efficiency across industries and around the world.

The Seven A3 Problem Solving Steps in Detail

The A3 process has many benefits. As updates are needed, it is erased and updated. Het probleem wordt herkend, erkend en geïdentificeerd door de teamleden van deze LEAN methode verbeterteam.

Lean Six Sigma A3

It was first used by Toyota and is quickly gaining popularity in industry today. The practice’s versatility is evident in the many ways practitioners refer to it.April 23, 2021.A3 in lean manufacturing is a problem-solving methodology and thinking process.Q: What are the main steps in the A3 problem-solving process?A: The A3 problem-solving process typically involves the following steps: problem identification and description, current condition analysis, goal. What Is An A3? SHARE ON: admin — June 25, 2021. Since the popularization of quality circles in the 1960s, companies around the globe continue engaging front line employees to improve their work using variations of PDCA, a scientific method for problem-solving using four steps: Plan a change or test aimed at improvement. It is most similar to the 11″ x 17″ size paper used in North America. This continuous improvement combo brings much-needed clarity to Kaizen Events, Projects or any process opportunity. Variants include 8D and CAPA. John Shook explains the three A's of the A3 in this video clip from the presentation that he and Lisa Yerian, chief improvement officer at Cleveland Clinic, delivered at LEI's Virtual Learning Experience. It is important to describe the actual issue at the start of your problem solving effort. The A3 approach is also known as SPS, which stands for Systematic . Compared to the DMAIC Framework of Six Sigma, Plan-Do-Check-Act (PDCA) in Lean . Companies must start to view problems as opportunities for improvement. C'est une démarche qui demande un engagement de la Direction et une mobilisation de l'ensemble de l'organisation, et qui donc s'accompagner d'une conduite au .comRecommandé pour vous en fonction de ce qui est populaire • Avis

Le rapport A3 : le Lean Management pour résoudre un problème

It visualizes the problem-solving process using a one-page document . But in the Lean Six Sigma world, it is a tool to help see the thinking behind the problem-solving. Understand current position. The approach typically uses a single sheet of ISO A3 -size paper, which is the source of .Basically, the A3 process is a structured template for solving problems in a continuous matter. We all may know DMAIC as it was born from the Scientific Method and the creation of Six .La méthode Lean peut se définir par la participation de chaque collaborateur ou employé à la réduction du gaspillage, par l’élimination de toutes les tâches inutiles, car non rentables.A3 problem solving is a Lean method to document, analyze, and propose solutions to problems on a single sheet of A3 paper. In this step, you make the business case for selecting a particular problem for resolution. It involves breaking down a problem into a series of steps, making it easier for . Developed as part of the respected Toyota Production System, an A3 is a tool . To be successful, this template must be supported by a lean culture that changes how we view problems.

Guide: A3 Problem Solving

The A3 process is a Toyota-pioneered practice of getting a problem, an analysis, a corrective action, and an action plan written down on a single sheet of large paper, often with the use of simple graphics. Various approaches and tools . The concept is, “If you need more paper, you don’t really understand it well enough yet.

How to Use A3 to Lead, Mentor, and Solve Problems

A3 Problem Solving proves particularly beneficial for managers and leaders, serving as an instrument to mentor others in problem-solving and to drive strategic initiatives.

A3 Thinking places a high value on developing agreements with all key stakeholders throughout the project. Step 1: Background.comLean Six Sigma A3 - Template & Examplegoleansixsigma. Alors c’est quoi un A3? L'A3 est une .Stappen van de A3 lean methode.La démarche Lean est un ensemble d'étapes qui vont permettre d'organiser le déploiement du Lean Management et de piloter l'amélioration continue à l'échelle de l'entreprise.So, the A3 is a way to capture and organize your plan-do-check-act ( PDCA ) problem-solving thinking, but completing it does not automatically lead to valid . It’s not just the A3 Report.Download our free A3 template and you’ll have everything you need to get started. Lean is a way of thinking about creating needed value with fewer resources and less waste.The A3 Report is a very useful problem solving and continuous improvement tool.More than the A3 size sheet of paper, it is a Lean tool that helps you structure your thinking and put together a story from beginning to end. This method: Implements strategic plans leading to increased customer satisfaction. Tools often provide traction for getting started with lean practice, and A3s often deliver immediate results.PDCA Cycle and A3 Problem Solving are clearly related.It is closely . It follows the Plan-Do-Check-Act cycle and uses visual tools to help you find root causes, . 3) it is set against a standard.

Like Toyota, Lean organizations often use the A3 process to manage work at the project, program, and portfolio levels. The A3 form is a structured way of solving problems using a detailed step-by-step methodology using the principles of the Plan-Do-Check-Act cycle. Upon your selection, clearly state how the problem impacts the strategic business objectives around customers, process, . Il s’agit donc de faire toujours plus, toujours plus vite et toujours mieux tout en améliorant les conditions de travail.The meaning of LEAN is to incline, deviate, or bend from a vertical position. It helps us follow a thinking process, facilitates communication, and builds consensus.An A3 is a one-page report prepared on a single 11 x 17 sheet of paper that adheres to the discipline of PDCA thinking as applied to collaborative problem solving, strategy development or reporting. The A3 is designed to be carried with you and is historically done with paper and pencil on the shop floor.Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and customers. The problem can only be addressed by understanding the current situation.Lean manufacturing, or lean production, is a system of techniques and activities for running a manufacturing or service operation.

A3: Thinking, Reports & Templates

The A3 is a problem-solving tool that encourages a collaborative and systematic approach to problem-solving.Write down on a post-it note what you think fast is, “Think about three attributes of a strong problem statement: 1) it is quantifiable. It helps us solve all kinds of operational and organizational problems, and it helps us plan. As she details how to problem-solve using the A3 . They used this size of paper because it was the largest size of paper that could be faxed, which was a common method for sharing information. The term A3 comes from the paper size which is roughly 11″ by 17″ and used to map . Why the best, most productive way to “start an A3” is by recognizing that the A3 problem-solving methodology is a “slow-thinking” process. With consensus, parties pull together, solutions are implemented quickly, obstacles are removed, and change can happen.

Lean manufacturing

An A3 is a simple one page format problem solving methodology that is .A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at Toyota and typically used by lean manufacturing practitioners.The A3 approach offers clear benefits that transcend conventional problem-solving methods.

A3 problem solving

And lean is a practice consisting of continuous .After a whole week of A3 training by an experienced Lean practitioner, the elegance and beauty of it started to become clear.

Questions and Coaching on A3 Thinking

The A3 problem-solving approach is a powerful tool used to identify, analyze and solve issues. Then I must mention team-based interactive ‘thinking together’ at all the right levels.