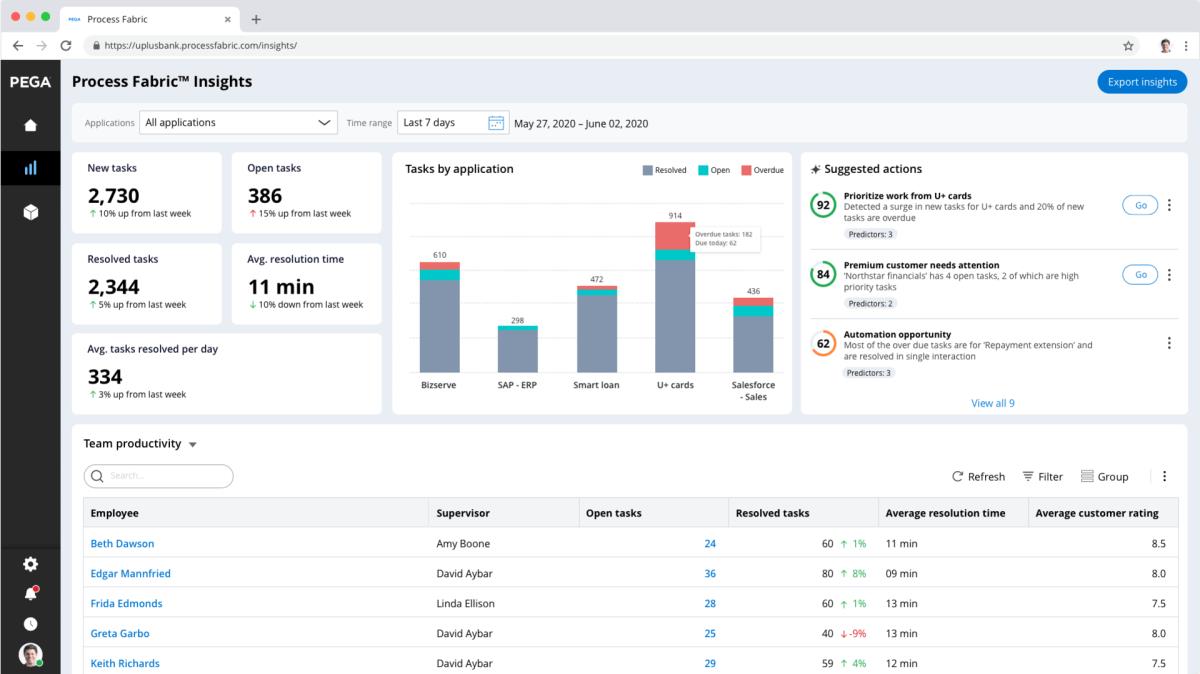

What is frp tank

FRP tanks, both above and below ground units, are a recognized and reliable option for fire suppression operations. The PVDF liner provides a chemically inert surface, while the FRP shell protects from physical damage.This manual is an overview of the Fiber Reinforced Plastic/Composite (FRP/Composite) material system.A considerable advantage of FRP is its lower cost. Materials and processes are presented along with design guidelines .

1252 FRP Filter Tank

These tanks are suitable for storing most inorganic and organic chemicals. It has a high strength-to-weight ratio, an .

FRP tanks are made of plastic that is reinforced with .

FRP Septic Tank Is Used for Environmental Protection

As per state or tank owner guidelines, a comprehensive inspection of both the interior and exterior surfaces of fiberglass tanks is typically required every 5 years.Excelling at process excellence. Mostly it is used for storage for daily consumptions. Before you begin installing the tank, you must make sure that the ground where it will be placed is level—so that pressure distribution is even inside the tank. Ensuring inspector safety is of utmost importance, .This chapter begins with a discussion on the basics of fiber-reinforced plastic (FRP) technology used in RTP-1 and Section X that may not be familiar to engineers and . Below are some advantages .

Since it has light weight, good strength, corrosion resistance and economic efficiency with molding as tank, FRP tank is used for many applications.

It’s our culture that ensures that QA processes are built into how we design, engineer, manufacture, and deliver every fiber-reinforced plastic storage container.FRP septic tank which adopts unique design and bio-film package, is especially suitable for the transformation and construction of old towns' sewer systems.Lower Initial Cost: Polypropylene tanks are generally less expensive to manufacture compared to FRP tanks. While FRPS is used widely in automotive, aerospace and the construction industry; GRP is more popularly used in the power industry.FRP Tank Inspections.

FRP Tanks

FRP tanks are created by reinforcing plastic with glass fibers to form a lightweight yet durable material that’s resistant to corrosion, impact and temperature . FRP storage tanks are ideal for storing a variety of chemicals and fuels because they do not easily rust and break apart.This chapter begins with a discussion on the basics of fiber-reinforced plastic (FRP) technology used in RTP-1 and Section X that may not be familiar to engineers and designers of metal vessels. 식품공장 공정탱크 (Fermentation Tank) 01 구조-FRP 재질 내식 및 강화층 (필요시 난연층)과 유리섬유로 제작된 바닥, 벽체, 상부경판 제작-JACKET은 FRP강화층 제작 -우레탄폼 보온과 마감은 FRP 강화층 제작-점검보수 맨홀과 노즐 (KS .

Your Guide to Buying FRP Storage Tanks

The FRP tank from Aceon is designed to be . It is highly resistant to heat and other corrosive substances. As a result of their high durability and anti-corrosive construction, FRP tanks have become popular in a variety of other industries, including fertilizing, refining, water treatment, metal extraction, Chlor-alkali producers, paper and . It describes the resins and reinforcing fibers included in RTP-1 and Section X. Various types of defects specific to fiberglass tanks are outlined in ASTM and RTP standards. Most fire protection systems require a tank in the 60,000-gallon range, which is simple work for a large capacity fiberglass reinforced plastic tank. Their superior resistance to corrosion secures the integrity of .Chat with an AM Tanks GRP tank expert today and order your new tanks, liners, and other accessories direct from one of America's leading commercial tank suppliers! If you're searching for lightweight, easily-installable frp tanks, then American tanks is right for you. Posted by Patrick Gannon on Jun 29, 2020.

A Beginner's Guide to PVDF+FRP Storage Tank Selection

Because these large tanks can be produced in the factory rather than built on .Fiber reinforced plastic (FRP), also called fiber reinforced polymer, is a composite material made of a polymer matrix reinforced with fibers. Standard FRP tanks with different colors and good-looking appearance.comRecommandé pour vous en fonction de ce qui est populaire • Avis At Allen Industries, our Six-Sigma Lean Manufacturing-trained staff eagerly accepts that quality is the responsibility of our entire team.FRP tanks are less expensive per gallon compared to drinking water quality reinforced concrete tanks up to the 250,000-gallon size range.FRP (Fibreglass Reinforced Plastics, also known as GRP, or Glass Reinforced Plastics) is a modern composite material of construction for chemical plant, pulp and paper mill, and . This corrosion resistance also makes FRP .

Concrete tanks will eventually hairline crack and leak to some degree – this means that small amounts of untreated groundwater may be infiltrating from outside.

A Comprehensive Guide to FRP Vessels & Tanks

FRP stands for Fiber Reinforced Plastic and it is composite material with thermosetting resin and fiber. Launch DroidKit on your computer and choose “FRP Bypass” mode.A PVDF+FRP tank can withstand a wide range of chemicals, including strong acids like sulfuric acid and nitric acid, and bases like sodium hydroxide.FRP, or Fiberglass-Reinforced Plastic, is a composite material made of glass fibers and epoxy resin. Augusta Fiberglass engineers and manufactures FRP . These tanks are incredibly eco-friendly. In many cases, FRP may offer both a satisfactory solution to corrosion problems and the lowest cost among material options.Temps de Lecture Estimé: 3 minThe FRP tank is mainly for the softener and treatment of water, which is widely used in industry and civil life, including chemical industry, light industry, textile, medicine, biology, food, electroplating waste water treatment, etc. In addition, the 1252 composite tank is made of a thermoplastic polymer compound, a carbon base material, and a core material from synthetic fibers such as organic fibers, glass fibers, basalt, silicon carbide, and carbon fibers.

HOW FRP USED TO MAKE TANKs AND VESSELS

Reinforced Plastic Storage Tank Manufacturing

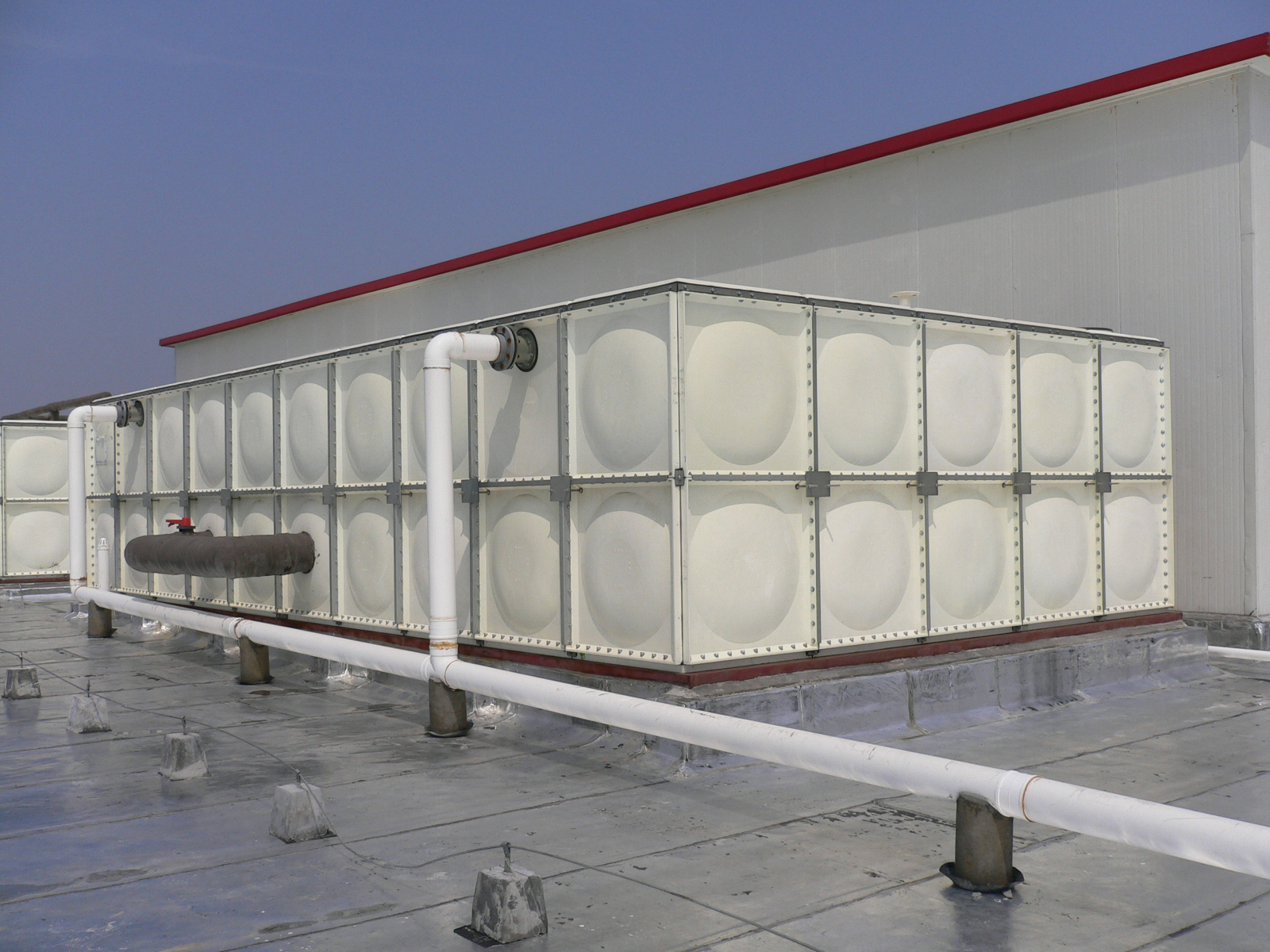

Detailed Technical Specifications of our Fibre-Reinforced Polymer (FRP) Panel Tanks for a wide range of Safe Water Storage and Retention. Sand, concrete, or pea gravel are good flooring substrates, but you need to ensure there aren’t any jagged edges on the floor where the .Fiber Reinforced Polymer composites are defined as a polymer (plastic) matrix, either thermoset or thermoplastic, that is reinforced (combined) with a fiber or other reinforcing . It is also widely applied in industrial districts, enterprise zones, residential areas, office buildings, schools, hospitals, public lavatories and other areas. Even though it’s a type of plastic, the fiber reinforcements make it stronger and less pliant. Their ability to offer higher resistance to .Industrial FRP Tanks.FRP Chemical Storage Tanks; FRP tanks are commonly used for chemical storage, solvents, alkalis, acid and other corrosive materials. We manufacture FRP Tanks of capacity ranging from hundreds of liters to gallons, these FRP tanks are designed and manufactured to withstand hydrostatic and dynamic water pressure. 고객만족을 위한 최고의 품질의 제품을 공급할 것을 약속드립니다. If corrective action is recommended, it can be identified at one or more of the stages in the process, including analysis of the cause, evaluation, and engineering of possible solutions, design, and execution. The chapter then discusses the following processes used to manufacture .Aceon manufactures FRP tanks for industrial usage in Malaysia.

Technical Design Guide for FRP Composite Products and Parts

netRecommandé pour vous en fonction de ce qui est populaire • Avis

Fibre-reinforced plastic tanks and vessels

Different specifications are available for wide application.

Maintaining & Repairing FRP Tanks and Pipes

They are corrosion-resistant. The tanks are designed to be lightweight, easy to install, .As a leading FRP water tank manufacturer in Malaysia, our FRP water tanks are coated with an interior chemical resin.comFRP Panel Water Tanks | Technical Specifications | Sunniksunnik. Its non-corroding properties greatly extend the life span of the tank and minimize maintenance.The Fiberglass Reinforced Polyester (FRP) Tank is completely rust free, which greatly improves sanitation – making it ideal for clean water storage.Fibre-reinforced polymer (FRP/GRP) is a strong but lightweight glass fibre-reinforced plastic composite used in the aerospace, automotive, marine and construction industries. FRP tanks are economical, lightweight, durable, and highly corrosion-resistant – they’re a smart choice for many . This modular tank enables the user to freely create the required capacity depending on the volume of water .The mechanical strength and elasticity of the plastics in FRP are made richer by including other materials.This article provides a systematic process/program for these external inspections that serves to increase reliability. Step 1: Download and Install DroidKit on your computer. Insurance demands are now requiring a dependable, . Steel tanks will eventually rust .Fiber reinforced polymers are used in many corrosive applications because the polymers provide superior corrosion protection to many metal alloys.FRP tanks are also a trustworthy option for personal storage, such as potable water or fuel.

Fiberglass Tank Construction: A Complete Guide

FRP is not recommended for carrying fluid with temperature more than 100 degrees celsius; Slight degradation from UV rays is found to occur which can be reduced by using pigments, dyes, UV stabilizers, fillers, etc in the resin system; FRP Storage Tank FRP Columns FRP Grids on walkways.

What is FRP water tank?

FRP Tank Installation Basics Floor Preparation.

What is the Life Expectancy of (FRP) Tank?

What most people call fiberglass tanks are actually known as fiberglass reinforced plastic (FRP) tanks.Tank flange fittings and accessories are installed using thermosetting resins per ASTM 4097. At FiberTech, we take pride in being one of the most sought after FRP storage tanks . They are available in a range of sizes and configurations, making them suitable for storing liquids in various industries, including water treatment, chemical processing, oil and gas, food and beverage, and pharmaceuticals. The cost advantage is particularly noticeable for standard-sized, non-customized tanks.comWhat Is The Difference Between FRP And Fiberglass?defifiberglass. FRP tanks may be filament wound or hand lay depending on size or a combination of both methods.

FRP Tanks Used in Water Treatment with High Performance

FRP tanks are widely used in the chemical industry in the following areas: chlor-alkali manufacturers, fertilizer, wood pulp and paper, metal extraction, refining, electroplating, brine, vinegar, food processing, and in air pollution control equipment, especially at .Checking FRP filter tank 1252 before delivery to customers.