Working with water based ink

Mar 24, 2021 Add to calendar.

Water Based Screen Printing Inks [the ultimate guide]

Pressure: Typically we use less pressure for plastisol printing, but water based ink needs to be driven into the shirt. Environmental rules may impose restrictions on the usage of specific compounds in water-based inks, so limiting the inks’ composition and performance. Still, we always recommend using high-quality marker paper when you are working with alcohol-based ink. We have additives for water-based inks, which keep them running on an automatic machine more easily. The example on the left shows two apples that were first outlined and shaded in using Sumi-i (black, non-permanent, water-based) ink.Gravure inks, flexographic inks, and dry laminating adhesives commonly used for packaging contain organic solvents.Water-based inks aren’t as production-friendly as plastisols. However, the resolution of this implementation is limited due to the rapid ink drying experienced at small size scales leading to nozzle clogging and low fidelity prints. Benefits of Using Plastisol. Curing Process and .WATER-BASED INKS compared with SB inks DISADVANTAGES •Water evaporates slower: ₋Less drying speed ₋Less resolubility THE SAME PROPERTIES •Cleaning . This article will touch on standard water . In addition to the environmental aspect, there are several functional reasons favoring the . Discharge ink is another type of water-based ink that works through a chemical reaction with the dyed cotton fibers.The only eco-friendly, water-based ink designed for digital printing on plastic flexible film packaging and other non-porous substrates.February 23, 2021. Step 1 : Krylon Kamar Varnish.Recommandé pour vous en fonction de ce qui est populaire • Avis

Everything Screen Printers Need to Know about Water-Based Ink

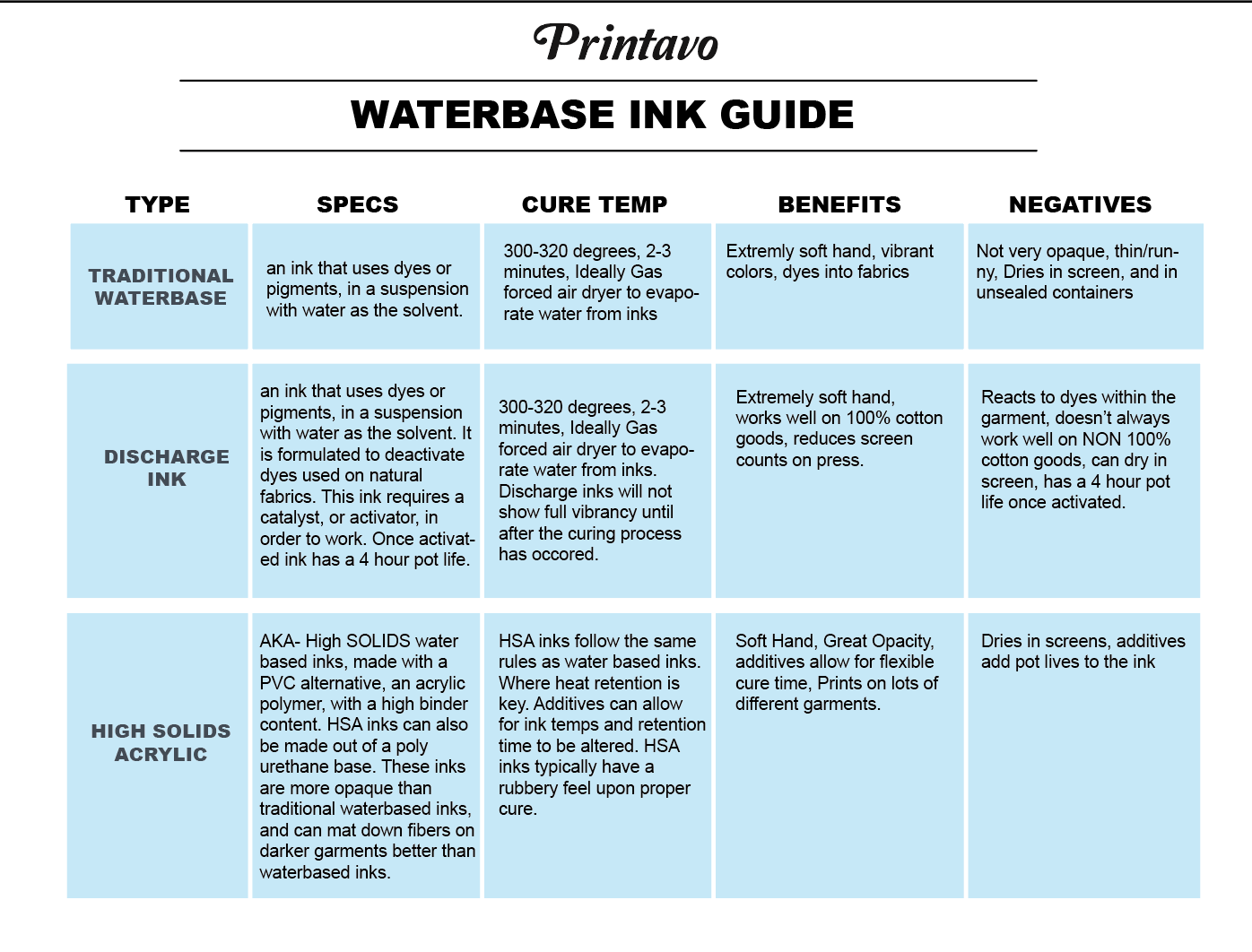

Unlike traditional water-based ink, discharge has a few extra ingredients and a discharge agent that’s mixed into the ink that causes the ink to extract the dyes in the fabric fibers, returning them to their natural . This low-migration ink delivers even and efficient coverage and drying with minimal heat, unlike light-curing inks. These inks are ideal for Intaglio/Etching, Monotype, Gel Printing, and Collagraph printmaking and can be used with Akua Liquid Pigment® and .Water-based block print inks.Safer for Workers.Unlike water-based inks, plastisol doesn’t dry out in the screen, offering a longer working time. You can’t just switch out the inks using the same prepress and printing procedures. After this, the ink layer can start to climb, getting hotter, and reach cure temperature.Compatibility with substrates: Water-based inks might not work well on all substrates, which would restrict their use in some sectors of the market or applications.2 Water-based inks are breathable.Using water-based ink, the curing process is one of the greatest challenges. An oil-based ink . Technology, Event.1 Water-based inks have a softer hand. The biggest thing we’ve come to figure out is that every job comes with its own headaches and challenges. Comparison Between Water-Based Ink and Plastisol. And this is the point, where I wanted to come to. To address this .Akua Intaglio Inks deliver brilliant colors, intense blacks and unmatched working properties. We are glad that you joined us and our experts from the PRETHINK INK network for a session on water-based ink technology.Water-based inks use water as a medium to bring pigments (colours) into the substrate.

A Guide to Use Waterbased Ink— The Right Way!

Waterbased Ink is completely free from harmful chemicals, and that’s why they are safe not just for the environment but also for the long-life of printers too. Therefore, all pump types with moving mechanical seals, such as gear pumps and piston, could be damaged by transporting water-based ink.What Is Water-Based Ink? Water-based screen printing inks are screen-printing inks that are water soluble. Water based glue will deteriorate with exposure to water based ink.

What is water-based ink?

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Water World: Tips for Printing with Water-Based Inks

Aqueous ink is often used for drawing, illustration and writing as it is more water-resistant than .Pallet: Use a spray glue to hold the shirt onto the pallet. Initially, screen printing was rudimentary, . 5Water-Based Ink . Sumi-i ink is re-soluble and would bleed or smear if you applied other water-based media over it (like watercolours or drawing inks), but when I used alcohol inks to . Try using the Euro mode “SQUEEGEE TO SQUEEGEE .Working With Alcohol-Based Inks . Unlike alcohol markers, water-based markers are . Be aware that printing with water-based inks is more difficult .

Water-based ink is composed of pigments held in a water-soluble binder, making it easier to use and clean up than traditional oil-based inks. Problems with the supply chain: The cost . With a lack of lubrication, abrasion and heat build-up, the pump starts leaking and may stop working.

For many reasons, ranging from ecology, through health and safety to economics and profitability, .Water-based markers have water-soluble ink, which can be easily wiped off and offer a better water color effect.

Lunajet water-based ink

Non-Toxic and Safe: Water-based ink is free from toxic chemicals, making it safer for printers, workers, and consumers, especially for printing on textiles and other products that come .Water-based ink technology: a more sustainable solution for flexible packaging. If you’re in the screen-printing industry, you’ve probably been hearing about the benefits of water-based ink: the . They can be used on both canvas and paper and work best on paper that has a smooth surface.Environmentally Friendly: Water-based ink has a lower environmental impact due to its reduced emission of volatile organic compounds (VOCs) and harmful chemicals.A water-based ink is quick drying, provides a lovely translucency with subtle gradations of tone, and can be easily cleaned up with soap and water. Screen printing has a long history, and over time, the inks used have evolved significantly. The ink dries very quickly when coming into contact with air so printers must work very quickly and efficiently whereas plastisol only dries with heated.A Beginner’s Guide to Artists Inks.

What is Water-Based Ink?

Water-based inks present a long list of benefits and have already been successfully deployed in other printing technologies, including offset litho, flexo and .5 Advantages of Screen Printing with Water-based Inks.

Best Practice Tips for Water-Based Inks

Seems pretty self-explanatory, right? I prefer using water based inks for my fabric printing, mostly because oil based inks are stickier, more smelly, and dry much more slowly.The water-based ink of today is much easier to handle than before. A water-based ink pen is any type of pen that uses an aqueous or water-based ink formulation.Drying water based inks – the challenges.Water-based ink do’s and don’ts.

Ultimate Beginner's Guide to Alcohol Inks (2024)

Winner: Water-based Ink.Best Practice Tips for Water-Based Inks. With WB it’s about maintaining a temperature range and holding in that range. By using water-water-based and solvent-free laminating adhesives that does not contain organic solvents, we can reduce CO 2 and VOC emissions from packaging, and improve the working environment during the printing .Best Practice Tips for Water-Based Inks - Screen Printing Magscreenprintingmag. 3Color Separation for Water-Based Inks. They do not dry out that fast, but for sure they still do. (hereinafter referred to as Kagem), founded in 1999, specializes in the R&D, production and sales of water-based inks, water-based varnishes, water-based acrylic resins, water-based acrylic emulsions, pearlescent binders and other eco-friendly water-based printing materials. 2The Ultimate Guide Water Based Printing Videos. Up the pressure and slow the print stroke down.If you have been reading up to this point, you should have an idea of which ink you should work with. 4Screen Making for Water Based Inks. Beyond the environmental advantages, water-based ink screen printing also enhances the safety and well-being of printing industry workers.Water Based Screen Printing Inks [the ultimate guide]screenprintingnow.Water based screen printing inks are great inks to work with when it comes to block printing on fabric. They dry through absorption-they will not dry on the printmaking plate-and clean up easily with soap and water. Shop on Amazon.The real keys to working with water-based inks is understanding their nature and applying the appropriate procedures to integrate them into the production . As the inks are alcohol based they evaporate much quicker, so the . Due to the low chemical risk associated with . Water–based inks are harder to work with. This works for me but feel free to adjust it to your needs. The type of work you’re making will mostly dictate the type of ink you settle on.We run water-based ink on 95 percent of our jobs.

![The best WATER BASED Ink for Screen Printing [Reviews 2023]](https://screenprinting-support.com/wp-content/uploads/2021/06/Screenshot_91-1024x576.png)

Most beginners start by using a water-based ink.3 Water-based inks last longer.comThe Basics of Water-Based Inks | Impressionsimpressionsmagazine. Many printers love how water-based ink is widely considered better for the environment and your shop.Water based ink, on the other hand, can be incredibly difficult to work with, especially to the untrained hand.

These inks are made from water, rather than other . October 4, 2023 by Tanith Hindley.

Drying water based inks

Artists Inks can be all kinds of consistencies – from milk-like acrylic inks to the stiffest oil-based printmaking inks.

What You Need to Know About Curing Water-Based Ink

Ecotex Water Based Ink.Stop The Smudging. Properties: High durability; Opaque finish; Heat cured, not air-dryable; Historical Context and Evolution of Inks.Buy: Speedball Oil-Based Block Printing Ink Set $33. Water-based inks can’t be topped when it comes to the softness of a print, versatility, and eco-credentials. Oil based inks can be used as well, but are better for use on paper.

In-Depth Industry Outlook: Water-Based Inks Market Size, Forecast

The results also depend upon the types of fabric, quality of ink, and type of printer. We have more knowledge on how to print water-based inks.What are they? Water-based inks require a longer drying time during the production process.

Best Block-Printing Inks

October 13, 2015.The basic answer is that water-based ink uses water as a base. The inks also require a different set of chemicals, emulsions, and equipment to . What Are Water-Based Markers? Water-based markers are basically made of water and pigment-based ink. Water-based markers are a great way to add color and texture to your artwork. Limitations of Plastisol Ink. If you can't access this brand, try to find a water based varnish/fixative so that it doesn't reactivate your inks. The more porous the paper, the fewer fibers it has to absorb and hold onto ink pigments. Here are some helpful “do’s and don’ts” for any screen . can be difficult to work with depending on .

Unlike alcohol markers, watercolor markers are .

The Basics of Water-Based Inks

I use the Ecotex Water Based Ink Kit for my screen printing as it's super easy to use and makes my prints look .Looking to create a soft-hand print that’s bright, opaque, and flexible? These inks are manipulated using isopropyl alcohol (rubbing alcohol to you and me).

How Water-Based Ink Screen Printing Reduces Environmental Impact

Alcohol ink is highly pigmented dye and, of course, alcohol based. Many screen-printing experts take this ink as a premium or special one.Direct-ink-writing type additive manufacturing with water-based inks such as hydrogels or polymer solutions is broadly utilized for bioprinting applications. But with some . They also dry very quickly so you can have a . Water-based inks smudge more because the water in the ink has to either be absorbed or evaporate for the pigment to stay where it was placed. By Nathan Foster, Contributing Writer. This 16-ounce jar of black water-based ink is an excellent, economical pick for classrooms and . They are different than plastisol inks for several . In general, water-based inks have quite a few advantages.4 You can achieve sharper detail with water-based inks. Water based inks dry fast, I .Plastisol Composition. 7 – Plastisol is Effective Cost Ink.