Are 3d printed parts durable

We recommend using .Nylon's impressive strength, flexibility, heat resistance, and surface finish enable 3D printing of durable real-world parts rivaling injection molding. Fillets are known for handling high-stress concentrations and therefore are the best choice for 3D printed parts that may need to endure pressure. These units can cost between $3,000 and $6,000.

A Comprehensive Analysis

3D printed houses are more durable than some other construction methods primarily because of the material used.Ultrasint® PP nat 01.Spotlight: Getting Familiar With the Lifespan of 3D-Printed Parts.

Which 3D printers print the toughest parts?

The Strongest 3D Printer Resins.

3D Printing Metal Parts and Materials

The FDM process is . Since PLA material has the lowest glass transition .Pro’s and Cons Chamfers vs Fillets. While we plan to make this article a general guide on the subject and keep the information we give on a practical level, there are still some things to consider before setting out to make your 3D printed parts .FDM models can usually cost between $150 and $300, although larger, high-end models can go up to $1,500. Stress relief heat treatments can . Manufacturing a sensor cover for 4x4 cars in CNC has a cost of 148 €, but in 3D they can be achieved for just 36 €.This paper presents the results of a study on the dimensional accuracy analysis of models produced by 3D printing technology—Fused Filament Fabrication . How to Make 3D Printed Parts Stronger?

What Is The Durability And Lifespan Of 3D Printed Parts?

But even with that .Applying paint or protective coatings can significantly enhance the resistance of 3D printed parts to outdoor elements. High-performance 3D printing materials are offering advanced properties. But, also ensuring that .

By increasing the infill density, you will print a sturdier and more robust part. This is both true in terms of resistance to impact and tensile strength. Stress Concentration. Things to Consider.The materials you can use include plastics, metals, ceramics, powders, resins, and much more. ASA filament is the best choice for 3D printed parts that will be outside and UV-exposed.

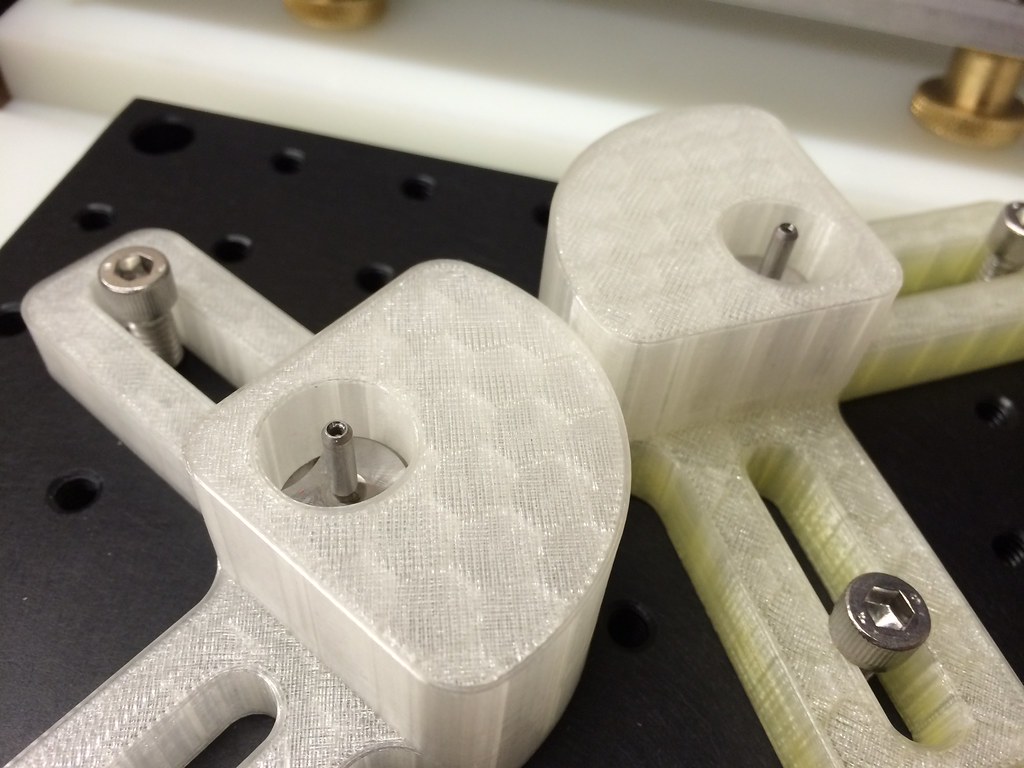

4x4 Cars with Durable 3D Printed Parts

Casting, welding, cold forming and machining processes induce residual stresses sometimes resulting in cracked components.

Depending on the type of flexible filament, you may need an extruder temperature of between 220C and 260C. by Leo Gregurić, Pranav Gharge, Gloria E. Direct Metal Printing (DMP) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means.Printed parts are 24x stronger than ABS, and just as strong as 6061 aluminium.

More expensive.

Are 3D Printed Objects Durable

In this article, I will explore the types of metals used in 3D printing; I will compare the strengths of different metals that printers use, what size parts companies can make using a 3D . Updated Apr 11, 2024.Pairing the right material with proper design and print settings optimises strength.ActivArmor offers an alternative that is durable, waterproof and contoured to the patient’s anatomy using data from a 3D scan. Choose Resilient Materials. This means selecting a quality material from a reliable supplier. Shop ASA filament here. It has enabled us to create complex . This article will give you more . Residual tensile stresses can cause warping or distortions and decrease fatigue strength. Printing with resin is more expensive, both in terms of the printer and the raw materials. Why settle for the ordinary when there are superior options out there? Opt for filaments like Polycarbonate with Carbon Fiber Reinforcement which is . Read on to learn how different factors influence the strength of 3D printed .Result: 76% savings on parts and hundreds of units in two weeks. Put our expertise to work for you today. Before casting work begins, the . Nylon is flexible when thin but its high inter-layer adhesion makes parts printed in nylon significantly stronger than any other common 3D printing feedstock. It is a durable, flexible, and highly versatile material that can be used to produce parts with varying degrees of hardness and softness, depending on its formulation.

Plastic 3D printing service

How to Make 3D Prints Stronger. Polycarbonate filament is highly . But what about durability? Are 3D-printed objects as strong and long-lasting as conventionally manufactured ones? In this .Preventative Maintenance. It might surprise you! At the same time, it’s slowly being used for more diverse applications because there’s a greater .Resin isn't the most durable material, but read on for how resin's 3D print strength compares to other materials. Acrylic paints or UV-resistant coatings can provide an extra layer of defense against UV radiation, moisture, and chemicals. Tweaking the 3D printer settings is not the only way to make a 3D print strong.3D printed parts in general can be just as strong and durable as similar components manufactured from other materials. Almost all popular filaments like ABS, PLA, PETG, Nylon, and . The extruder’s cold end channels filament to the hot end, ensuring a smooth transition from solid to melted filament onto the print surface.Cons of 3D printing using resins. This 3D printing material has really high rigidity and toughness.So, how strong are 3D printed parts? 3D printed parts can be incredibly strong. 3D Printed Parts.Residual stress and cracking are major problems in 3D-printed metal part manufacturing.Tell us, as well as discussing the issues with these parts in the 3D Printed Gears forum over at 3DPB. When created with the right materials, they can withstand pressure up to 9,800 psi and temperatures as high as 428 .When it comes down to strength, FDM printed parts tend to be stronger than resin printed objects. These coatings help prevent color fading, enhance weather resistance, and improve overall durability.The most widespread 3D-printing material, polylactic acid (PLA), is a biodegradable plastic made from renewable sources like corn starch.

(Exploring Longevity & Strength!)

Printing a model with 100% would take forever and spend way too much material.Need Pricing for Your Part? Not in the market for a printer but want to understand pricing for your part? Get a quote from a certified Carbon production partner. Mighty Buildings. The biggest factor when making a more durable . Annealing 3D Prints. Ultimately, resin 3D printing has come a long way in terms of strength and can be used for a wide variety of applications. There is a reason why many car . ABS-Like resin is a catch-all term used for what we’ll call the more standard type of robust 3D printer resin.3D printing has taken the world by storm, revolutionizing the way we design and create things. April 26, 2021. All manufactured materials have defects that can ultimately lead to their failure. The higher end 3D printers open your ability to print with more materials but they can get .Nylon is a high-performance material that can be used to print incredibly durable parts, strong enough to be used as pieces in commercially-available products. Aside from the epoxy coating, which is a post-processing method, there are other methods you can use. It might surprise you! It’s a given that resin 3D printing produces highly detailed and accurate parts with very nice surface finishes.The 3D printer extruder is the central hub of the printing process, and covers both the cold end and the hot end. Are there any materials that are particularly well-suited for durable 3D printed parts? Let’s discuss these differences in more detail.Polycarbonate is widely recognized in the 3D printing community as the most durable 3D filament in strength and resilience.

The most popular material you’ll see is plastics, more so PLA and ABS because of their ease of use and compatibility with most 3D printers in the market. Just like a lot of other things in 3D printing, there is more than one method of achieving this goal.

(PLA, ABS, PETG

The printing parameters influence the electrical, thermal, and mechanical properties and weather resistance of the 3D-printed part (Ref 3). The 3D printed casts and splints make it possible to X-ray the injury without removal; easily monitor the skin; and even allow the patient to swim, exercise and bathe as usual.As there are many different types of polymers, 3D printed plastic parts tend to vary in strength. This makes PC an excellent choice for parts exposed to harsh conditions or requiring a high .This can increase tensile strength by up to 70%. Furthermore, nylon . This includes the quality of the printer, the printing process, and the settings used during printing, . This also depends on build orientation and technology.3D Systems invented 3D printing over 30 years ago.To make those parts, Magnus Metal borrows elements of sand casting and 3D printing to perform what it calls digital casting.How strong 3D printed parts are depends on several key aspects, including: The material you use for printing, and; How you design and print your 3D parts. Another advantage of 3D printing in stainless steel is the possibility of creating large objects with fantastic surface quality and resolution. Depending on the chosen stainless steel material, parts can withstand temperatures of up to 800°C. Typically, if you want a professional-grade printer, you must pay extra for the privilege. 3D Printer Parts: The Top 10 Stores Online. The hot end of a 3D printer is where the filament melts before deposition through the nozzle. It has excellent chemical resistance and is perfect for industrial goods.

How Durable Are 3D Printed Objects?

3D Printing in Stainless Steel

Several startups are positioning 3D printing as the next, most . 3D printers solve this issue by keeping the inside hollow to an acceptable degree.

5 Strongest 3D Printer Resins Ranked 2024 (Every Type)

As the fillet can share stress over a larger area, it can considerably reduce the chance of .While 3D printed metals may be prone to cracking, 3D printers produce metals for uses in space travel, medical components, rocket engines, and jet turbos.In this guide, we will give a couple of tips on how to achieve durable parts that will serve you for a long time. For a heated bed, it can be optional for . ABS-Like Tough Resin. In addition, the IMES 3D team designs the piece in a .A Comprehensive Analysis. [SOURCE: NewsWatch ] Subscribe to Our Email Newsletter Our Ultrasint® PP nat 01 is a high-performance material that can be used in the automotive industry.

3D Printer Parts: The Top 10 Stores Online

But keep in mind that high infill density might be a double-edged sword. Thanks to this technology, IMES 3D can offer durable parts and more competitive prices to its customers.When incorporated into 3D printing filaments, these characteristics imbue printed parts with exceptional mechanical properties, making them ideal for a large variety of applications. 1000 Subscriber Special!! 3D printing has revolutionized the way we manufacture objects.Resin isn’t the most durable material, but read on for how resin’s 3D print strength compares to other materials. When meticulous protocols are followed, users .Recommended 3D printer settings for ASA filament: Extruder Temp: 240±10 °C; Bed Temp: 95±10 °C ; Learn how to succeed with ASA filament in our in-depth guide here.Additive Manufacturing Materials are Transforming 3D Printed Part Durability Historically, additive manufacturing materials have been brittle and exhibit .

How Strong Are 3D-Printed Metal Parts?

As the name implies, it pulls in some of the properties of ABS: shatter-proof, decent levels of detail, impact-resistant, and heat-resistant. Below are two important methods popular recent.The most adaptable material for 3D printing with flexibility is TPU (Thermoplastic Polyurethane). These manufacturers . Whether parts . Hobby resin 3D printers often cost between $180 and $900.

Boosting Strength: 11 Tips for Ultra-Durable 3D Printed Creations!

From intricate jewelry pieces to large-scale building models, 3D printers can produce just about anything you can imagine.

Why 3D Printing Materials Matter.

However, moisture control, printer upgrades, tuned print settings, and post-processing techniques are prerequisites to leverage these benefits.

The Pros and Cons of Resin-based 3D Printing

There are two versions of The Mark One – The Mark OneStandard and The . Polycarbonate Filament.

:max_bytes(150000):strip_icc()/1099r-eda9fdcb4d82449da27f9f30a318aaa3.jpg)

_3 - Photo.jpg)