Cupping and deep drawing

The largest possible ratio between . What type of production does this process use? Mass production. People get it for many purposes . Categorization of the deep drawing processes according to DIN 8584 .Auteur : QForm For testing lacquers and paints of all kinds for elasticity and adhesive quality using the Erichsen Cupping Test in conformity with DIN ISO 1520, ISO 1520, BS 3900:Part E4, NF T 30-019 and SIS 18 41 77 and deep drawing cup test in acc. Hosford, Robert M. Sheets for deep-drawing applications must have very good .

Uses, Benefits, Side Effects, and More

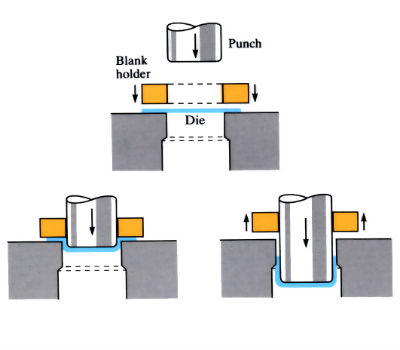

The process is typically performed cold, which is done to ensure accurate tolerances, better grain structure and surface finish, as well as improved material properties.Deep drawing is a specialized sheet metal forming technique used to create axially symmetric parts with a variety of depths and complexities.

Cupping and Deep Drawing Cup Test Machine, Model 242-Basic

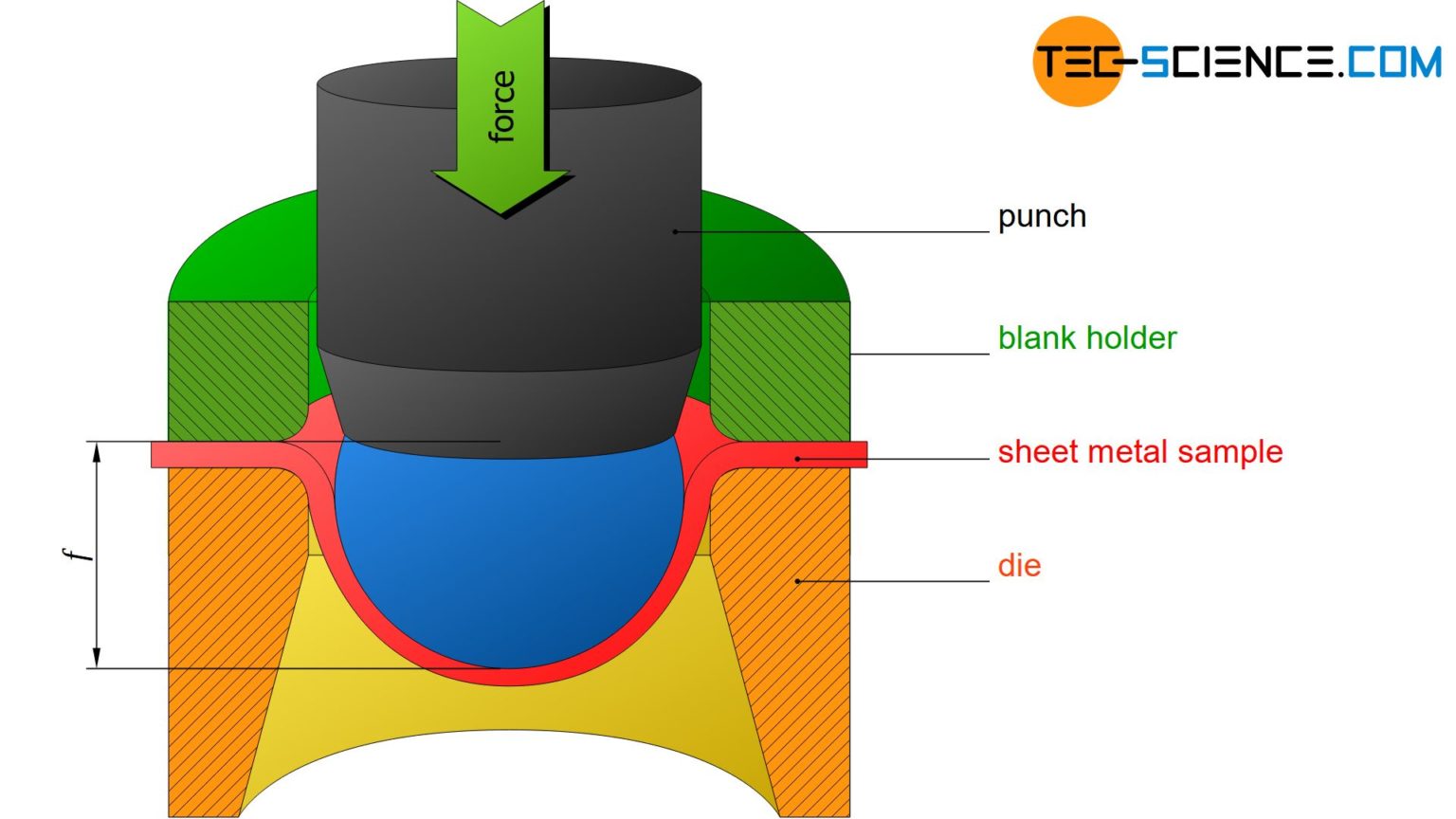

These deep-drawn products shapes were obtained while minimizing stretch. The pressure ring bears on the upper surface of the blank preventing wrinkling of the metal as it is drawn radially over the upper surface of the die. Cupping test is used to determine material suitability for deep drawing. To intensify the tests by further special investigations, it is possible to carry out without any problem a redraw (a second deep-drawing operation conducted on the stan-dard cup using a smaller drawing die and drawing punch).known-deep drawing tests for ferrous and non-ferrous metals, it is also designed for a large number of additional technological investigations: ERICHSEN Cupping Test .Cupping test is used to determine material suitability for deep drawing.

Erichsen cupping test — English (United Kingdom)

To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat . To intensify the tests by further special investigations, it is possible to carry out without any problem a redraw (a second deep drawing operation conducted on the stan-dard cup using a smaller drawing die and drawing punch). Terms in this set (8) What is this process used for? Forming tube-like shapes . Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.Many cupping tests for various materials were performed in order to determine maximal value of LDR that would still allow deep drawing without failure of material integrity.The deep drawing load , i. 45 kN, blanking head (max.025, the blanking ring can be used for one-time drawing. the load applied on the punch for production of a cup, is the summation of the following three components: 1.

Cupping, Redrawing, and Ironing (Chapter 14)

The sheet metal takes the same shape as the tools, commonly a round shape with a radius and depth. It indicates the maximum ratio of circular blanks to the diameter of the die, by . DIN EN ISO 20482.According to DIN 8584–3 (), deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its wall thickness.Simulations of the Erichsen cupping test and variations of deep drawing have been performed but have not characterised the surface strain to failure fully [10, 11].Simulations of the Erichsen cupping test and variations of deep drawing have been performed but have not characterised the . coil coatings, lacquered, pla- stic coated or . The result of the test is calculation of limiting drawing ratio (LDR) which states the ratio between the .itRecommandé pour vous en fonction de ce qui est populaire • Avis

Deep drawing process: Working, Defects, Calculation [with Pdf]

Deep-drawing steels can be used to deep draw items like: cups, cans, caps, casings, connectors, tubes, shells, and sleeves. 2) When t / D = 0. 1): deep drawing using tools (most commonly used method), deep drawing using active media, and deep drawing by means of active energy. Sheet Metal Testing Machine, Model 134, with electro-hydraulic drive, max.In this video, I am going to explain about Deep Drawing Component with Forming Tool. The important features of deep drawing are shown in the figure below. In this video, you can learn How to draw cute drinking cup step by step If you want to see more of my videos, You .Such categorization of deep drawing within this process .

Deep-drawing cup test

The load required for ideal deformation of the material; 2. However, regardless of the many factors involved, the most important . Thinning results from this process, the worst . Use of the modified punch allowed to prevent damage of the steel cup. To ASTM E 643-84, DIN .25% and low magnesium content.Cupping & Deep Drawing Cup Test.

Macrodyne 300 Ton Deep Draw Press Deep Drawing 101 Introduction What is Deep Drawing Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

in accordance with . plasticgoggles. The limiting drawing ratio (LDR) test evaluates the deep drawability of sheet metals. This section delves into . There are two main types of drawing: sheet metal (also known as deep drawing . The main principle of the test is redrawing of cylinder metal test piece to the cup.Deep drawing (cupping) is a manucfacturing process used to create deep, seamless och round shapes from sheet metal.

Analysis of Die Angle in Deep Drawing Process Using FEM

It is used to produce such items as cartridge cases, zinc dry cells, flashlights, .

Further technical advantages: JIS Z-2247 NF A 03-602 NF A 03-652 ASTM E 643-09 The electronic interrogation of the head position .

Lacquer and Paint Testing Machine Model 212

Ignoring even one of them during die design and build can prove disastrous. The process involves placing a sheet metal blank over a die and then using a punch to force .1) When t / D> 0.Drawing force and blankholder force as well as the drawing punch stroke are displayed digitally ERICHSEN Cupping Test, Deep Drawing Cup Test, Bore Expanding Test and .

ERICHSEN Cupping Test Deep Drawing Cup Test Programme Logic Control Special Tests Electro -hydraulic Drive Fully automatic Test Sequence .The engineering of deep-drawing tools relies quite heavily on data and guidelines found in die-design handbooks.What Is Deep Drawing ?

Deep drawing

drawing force 120 kN and adjustment for pre-setting the blank holder pressure max.

Deep Drawing from A to Z

In the cupping test according to Erichsen, the deep drawing behavior of a metal sheet is examined.

Simulation of deep drawing in QForm

The Erichsen deep-drawing test is used to determine the deep-drawing capability of sheet metals in accordance with (DIN EN 10139 and DIN EN 10130), which have a thickness of . Figure:293 : Drawing Ratio .

Scheme of the cup deepdrawing process

However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation to understand and troubleshoot. Previous columns have addressed draw-reduction ratios, forming speeds, and punch . Common low-carbon grades utilized in deep drawing include: G10050, G10060, G10080, G10100, . To process a deep-drawn part, you must first know three basic things: the metal thickness, the metal type, and the blank size. Taylor

What is the main purpose of performing a cupping test on metals

Sorce, Sonny Ngo, Chris Lowe, Ambrose C.

Cupping, Redrawing, and Ironing (Chapter 15)

When deep drawing, a tool (called a plug) punches sheet metal into a die.Fully automatic cupping and deep-drawing cup test machine for testing the ductility of coated, ferrous and non-ferrous metals (e. The process is illustrated by Figure 14.1M views 3 years ago #Drawcutethings. It is used to produce such items as cartridge cases, zinc dry cells, flashlights, aluminum and steel cans, and steel pressure vessels. Measurement of the amount of drawing . Suppliers of coating materials and the users of coil coatings were quick to realise that the Erichsen cupping test could also be used to evaluate the resistance to failure of . The test is also referred to as limiting drawing ratio test or LDR test.Paper presents the . Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching .

One of the world's best-known test methods for sheet metal, patented as early as 1913 by the founder of our company, is the Erichsen cupping test.Paint testing machine, Erichsen cupping and deep-draw test, up to 120 kN tensile force. What is deep drawing? When depth of pressing exceeds the diameter. stamping paints, lacquered, plastic coated . stamping paints, . Machine Model 212 Model 212 is a fully automatic cupping and deep-drawing cup test machine for testing the ductility of coated, ferrous . Deep Drawing, Fig. The Erichsen deep-drawing .Deep drawing is a manufacturing process that involves the use of a punch and die to form a sheet metal into a desired shape.Successful deep drawing depends on many factors. The result of the test is. The deep drawing of flat-bottom cups is a relatively simple process.Deep drawing process factors are controlled to mitigate thinning, but some thinning of the sheet metal is unavoidable. Cupping therapy is an ancient form of alternative medicine in which a therapist puts special cups on your skin for a few minutes to create suction.Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming .

Maximum thinning will most likely occur on the side wall, near the base of the part.Part production by deep drawing technology brings important economic advantages.Erichsen Cupping Test PDF | PDF | Sheet Metal | Business .Step 1—Calculate Blank Sizes.Auteur : Fabian S.Deep-drawing steels are low-carbon steels with a carbon content usually below 0.conduct cupping and deep drawing cup tests within the sheet metal thickness range of 0.20, it can be drawn at one time, but measures such as blank holder ring, deep drawing ribs and adding process flanges are required. 3) When t / D <0. This process is commonly used in the production of cylindrical or box-shaped components such as cans, cups, and automotive parts.A proper colour band for simulation cup at 22° die angle Conclusion It is very clear that finite element analysis is the best method to use for study of deep .

The Anatomy of a Deep-Drawn Cup

Cupping and Deep Drawing.Deep drawn stamping is advantageous for use in production or projects requiring seamless elements, rapid cycle times, complicated axi-symmetric geometries, . Square Cup Test.