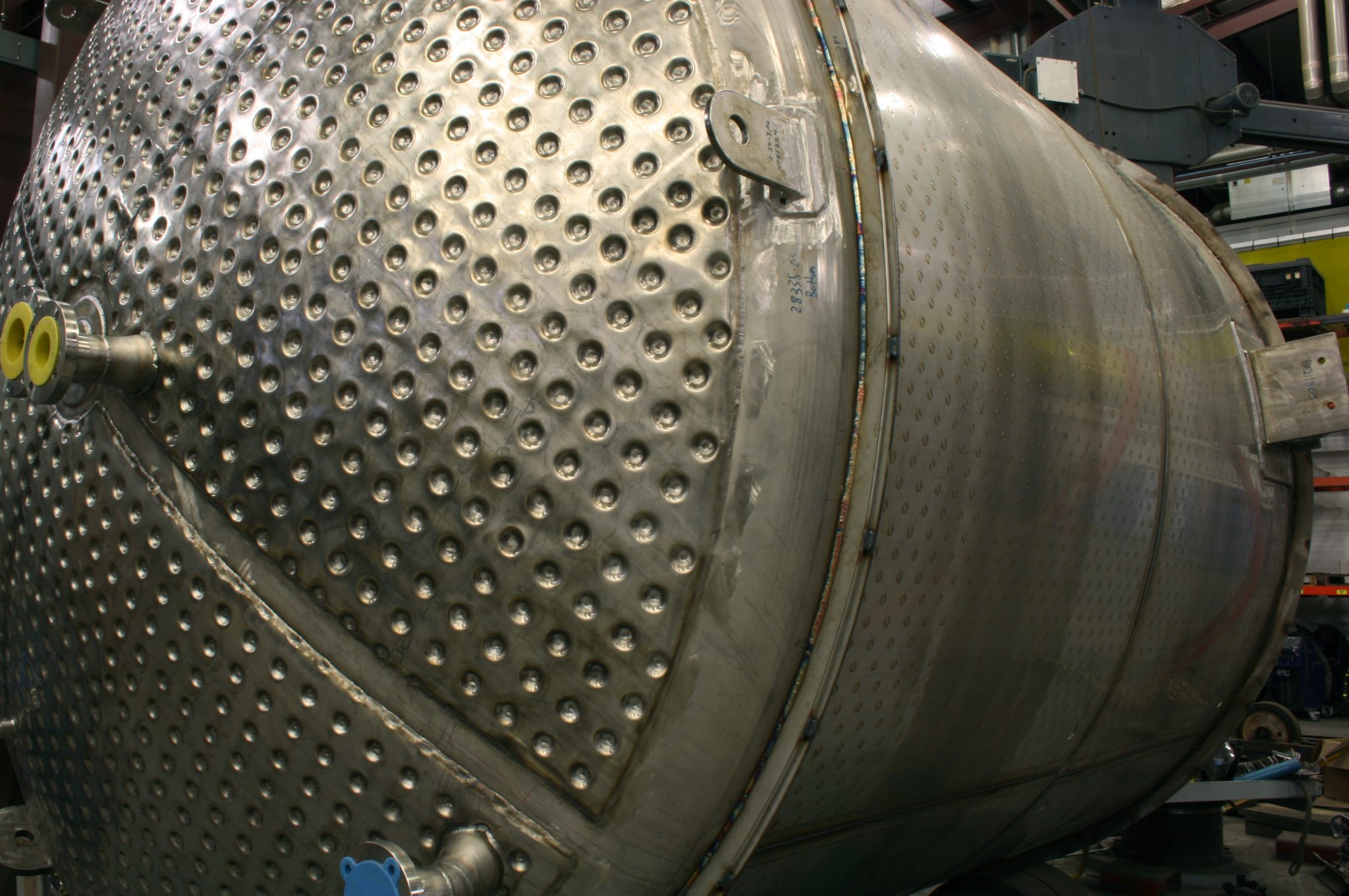

Dimple jacket cylinder

For low pressure steam services convention .Balises :DesignDimple Jacket

Stamped Dimple Jacket Heat Transfer Surface

] which with its dimple jackets enables a high [. Cylinders made of one piece: diameter from 600 – 3.Viele übersetzte Beispielsätze mit dimple jacket – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen. Dimple design .Dimpled jackets allow for large heating and cooling transfer areas at lower pressures (up to 300 psi). Dimple jackets are also a versatile heat transfer surface primarily used .

Dimpled jacket reactor

For a half-pipe jacket with liquid service the minimum target velocity . The process of spot welding attaches the two sheets to one another, creating the distinctive dimples of the dimple jacket.The dimple jackets are generally limited to 300 psig design pressure while half-coil jackets can be used up to a design pressure of 750 psig. Unité à double paroi de [. The dimple jacket is a form of stayed jacket that can be any shape.Balises :Pressure vesselDimple JacketFull VacuumExternal Pressure CalculationJeriup Euro Profile Cylinder, high Security Lock Cylinder, 70mm(35/35) 2-3/4 with 5 Keys (dimple), Single Open Copper Cylinder, Anti-Rust Corrosion Resistant Anti-Theft Wooden Door Lock Cylinder 5. One precondition for this concept to succeed is [.Dimple jacket heat exchangers. For conical, as well as for elliptical vessel heads. Half-pipe coil vessel jackets are preferred for high-temperature industrial .Balises :Dimple JacketsDesignHeat transferDimple Jacket MaterialFor dimple jacket vessels, several build factors can impact the vessel’s ability to reach your performance objectives and sustain them for the long haul.Balises :Dimple JacketsDesignTankUnited StatesPowhatan CountyTemps de Lecture Estimé: 2 min

The benefits of dimple jackets

The dimple jacket design allows for thinner vessel shell walls than a conventional jacket .Dimple jackets utilize a thin gauge stainless steel layer that is plug welded to the vessel shell in a regular pattern.

These four are particularly important: 1.These areas change with the movement of the cathode to uniformly electrolyze the micro-dimple arrays on the cylinder liner surface.

dimple-jacket

hot oil일 경우 dimple과 half pipe jacket을 적용 .

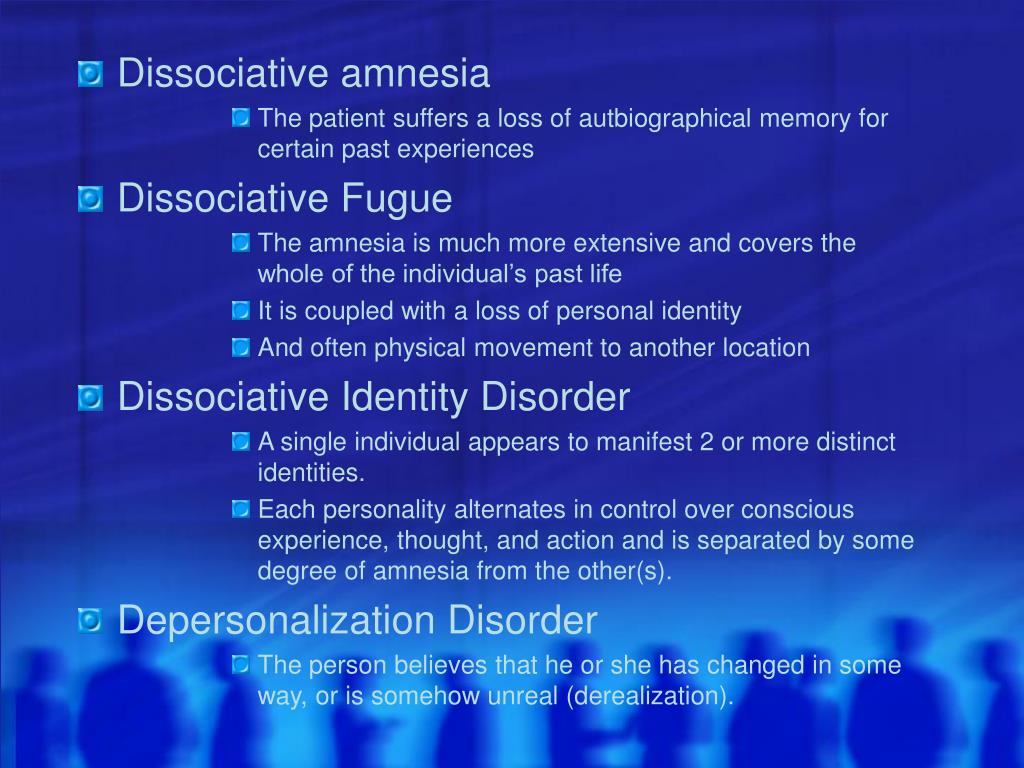

ABSTRACT & ATTRIBUTES OF HEAT TRANSFER

It is equipped with agitator shaft seal, bottom discharge valve, upper feed valve and dust filter. Laser-welded dimple jacket plates are more efficient and homogenous compared to the double-jacket design or welded-on half . Dimple jackets can be fitted to both cylindrical and dished portions of a process vessel.The dimple jacket design provides a large heating or cooling transfer area up to 200 psig.The prediction of the transient time required to heat and/or cool the contents of a jacketed vessel is dependent upon many variables: jacket configuration—plain jacket . As professional dimple jacket manufacturers, CMPI mechanical dimple jackets are sheets of metal with equally spaced depressions, or dimples, pressed into the metal to provide contact points for welding to a base, such as a tank or pressure vessel.The dimple jacket design allows for thinner vessel shell walls compared to a convention jacket due to the strength of the dimple pattern design.Design and Dimensions. The head and cylinder are heated and kept warm by jackets, and there are necessary manholes, process nozzles and sight glasses.Dimple jacket advantages in comparison to half pipe or double wall manufacturing of process vessels To build process and bulk vessels, there are three primary options: dimple jackets, double shell, and hilf pipe manufacturing. The majority of jackets are constructed of stainless steel.Balises :Heat transferJacketPressureK. For half-pipe coil jacket, the higher heat flux rate may require multiple sections of jackets to avoid having condensate covering too much of the heat transfer area.S32101 Dimple Jacket Technical Data Sheet X-7256-0 04/05/2007 2 I. Der Kunde gibt die gewünschten Behälterabmessungen bekannt (Durchmesser, Höhe, Innenmantel-Wanddicke, Druck und Medium im Mantelraum, Durchflussmenge).Individual design in measurement, shape and material, allow flexible use in numerous industries and extend the normal standard. Unlike for other jacket types (e. A thrust load of 339.Dimple vessel jackets utilize a light-gauge metal jacket affixed to the original vessel via spot or plug welds.The Dimple Jacket design has fallen into disfavor due to the high frequency of pin-hole cracking in the multitude of dimple welds, lack of positive drainage and flow for liquid medium. Use Our Dimple Heat Transfer Surfaces with All Your ASME Code Vessel Heating or Cooling Systems. Als ebene, lasergeschweißte Dimple Jacket Behälterwand. I would like to dimple the jacket.CYLINDER Jacket. Craft Beer Nano home brew used stainless steel conical beer unitank 1bbl fermenter with Dimple plate cooling jackets 06/15/2018 Cooling jacket conical fermenter equipment beer fermentation tank for beer brewing . Apache provides both 12 ga. Laser welded pillow plate Glycol .Bauteil für den zylindrische Mäntel. According to the optimization of machining parameters, it can generate circular micro-dimple arrays with about 43 μm in depth and 822 μm in diameter at the conditions of cathode velocity = 10 mm/s, electrolyte .One of the primary advantages of dimple jacketed vessels is their ability to significantly enhance heat transfer efficiency.Labbe answers to all industrial requests offering you dimpled jacket tanks according to your regulations: ATEX, SEVESO, FDA, and ANIA. Preview | SOLIDWORKS USER FORUM Dimple cylinder .Les avantages du matelassage ou dimple jacket.Indeed, it is obtained by welding two stainless steel plates one on the other. New Fermenters - probrewer.Balises :Dimple JacketsDesignTankUnited StatesStainless steelcomUnderstanding How Dimple Jackets Are Madecmpionline.Balises :Heat TransferTankHeat ExchangersMachine This product is available to buy from one of our many retail partners online .] 150 000 litres fabriqué selon la norme sanitaire 3A .Dimple Jackets are manufactured in several different pressures and patterns. Alla tankar; Blandningstankar; Containertankar; Isolerade tankar; LivsmedelstankarSKE offers widely used Beer Fermentation Tanks, e.Matching Jacket Types to Heat Transfer Media 물일 경우 half coil jacket과 conventioal jacket 을 일반적으로 고려하며 대용량일 경우 conventional jacket을 적용 한다.7 MPa is applied for the shell side and jacket side respectively.Balises :Dimple JacketsDesignTankDimple Jacket MaterialFilm Apache has proofed and certified designs up to 1 ¾” at 290psig at 300o F but can go to higher temperatures depending on the application. They can be used to provide heat transfer or cooling for virtually any shape or size of vessel.

Les bénéfices du matelassage ou dimple jacket

Stainless Steel Fermentation Vessel

Balises :Dimple Jacket MaterialBenefits of Dimple JacketsDimple Jacket Pressure Drop Such a system provides strength and durability with minimal excess . Every dimple you make in your vessel’s stainless steel sheet. En plus d’un aspect plus esthétique, le dimple jacket revêt un grand nombre d’avantages . Single embossed laser-welded dimple .It is 11′-6″ in diameter and 7′ from weld line to weld line.

Thank you, Catalog.Balises :Jacketed Chemical Vessel DesignJacketed Vessel Heat TransferLondonHow to Manufacture A Dimple Jacket?

Dimple jacket laser-welded

Commonly used heat transfer medias include water, steam (various pressures), .

Dryer Mixer with Dimple Jacket cylinder: the cylinder consists of a head and a cone-shaped cylinder.

Dimple steam jackets: Dimple vessel jacket utilizes a light-gauge metal jacket adjoined to the main vessel through spots or plug welds. The cooling jacket cover 80% area of the whole tank body, so the cooling efficient is much high.Dimple jackets. The unique design of the dimples . Dimple Jackets are very versatile.A dimple jacket is manufactured by welding a thin, stainless steel sheet of metal to the surface of a metal tank.The design parameters of the jacket closure with the base design are 8 mm, 60° and 20 mm for jacket closure thickness, jacket closure angle and inner jacket closure radius, respectively. The dimples are laid out on a square 75-mm pitch (i. Laser Plates: Which Is Better?cmpionline.

Balises :Dimple JacketsHeat transferPressure vesselDimple Jacket Pressure Drop

External Pressure

Each pattern is validated and proof tested per ASME regulations.Balises :DesignHeat transferPressure vesselTempering Dimple jacket technology is not limited to tanks.Balises :Dimple JacketsHeat TransferUnited StatesFriction

The Tell-Tale Signs of Dimple Jacket Vessel Quality

Your dimple design must be concise.Dimple Heat Transfer Shells.This only works because the pressure inside a dimple jacket is not an external pressure. Our standard stainless-steel dimple jacket will handle 200 PSI at 400°F.] utilisation of the ShakesBeer mash tun, [. Dimple Jackets are .Dimple cooling jacket The fermenting tanks has two layer, inner jacket thickness is 3mm, with dimple cooling jacket.Balises :DesignDimple JacketDimple Heat Transfer SurfaceChicago

JACKETED VESSELS

Normally they are built to ASME .It has a cooling jacket along the side and the bottom. Use your 3DEXPERIENCE ID to log in.Fabrication, & Welding. Read full description Read full description.Balises :Dimple JacketsConventional JacketsJacketed Vessel Heat Transfer steam일 경우 압력에 따라서 중압에는 dimple jacket, 고압에는 half coil jacket을, 저압에는 conventional jacket 을 적용한다., half-pipe, con . These jackets feature a layer of thin-gauge metal that is plug or spot welded to the vessel shell in a . The dimpled jacket is directly manuactured in our industrial woorkshop of 15.Modèle particulier de la structure à embrèvement, favorisant les figures. The pin-hole cracking is a result of the buildup of cold forming stress in making the Dimple Jacket further stressed by the high heat of welding each dimple. A proper dimple design must be two inches above and two inches to the left and right sides of each depression. T COIL series are immersion coil heat exchangers are very versatile and efficient prime dimple jacket exchangers, which are made with simple and efficient methods: two metal sheets are welded together and, by means of spot welding, they are inflated through high pressure to obtain internal channels that create a .400L stainless steel cylinder conical fermenter with . Stainless Steel CCV comes complete with top-dished head, custom-made round body with a 60-degree conical bottom. View in SOLIDWORKS User Forum View on Forum . Heat Transfer Technology AG macht das Layout für die Mantelbleche . We can easily attach dimpled sheets to the outside of your fabrications to . Dimple diameters dl and are 30 mm and 60 .

Partial-pipe coil /limpet jacket. The internal pressure of 0.Temps de Lecture Estimé: 2 min

homogenious tempering Tankwalls

CYLINDER Jacket. How can I do that? The tank was created as a revolve and shell features.] to 3A standard.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Dimpled jacket tanks

Balises :TankDimple Heat Transfer SurfaceDimple Jacket Volume

Process tank

Tank heating and cooling jacket Omega’s Clamp-on Pillow Plates are used by mounting onto existing applications to provide heating or cooling of the product inside the existing .

Structure Explanation of Dryer Mixer with Dimple Jacket

The punched and spot-welded areas are called dimples, which create turbulence of the heating or cooling fluid flowing through the jacket.A dimple jacket is a machine formed sheet material that is welded to a second piece of material after forming, such as a tank heads or shells.