Hydraulic gear pump efficiency

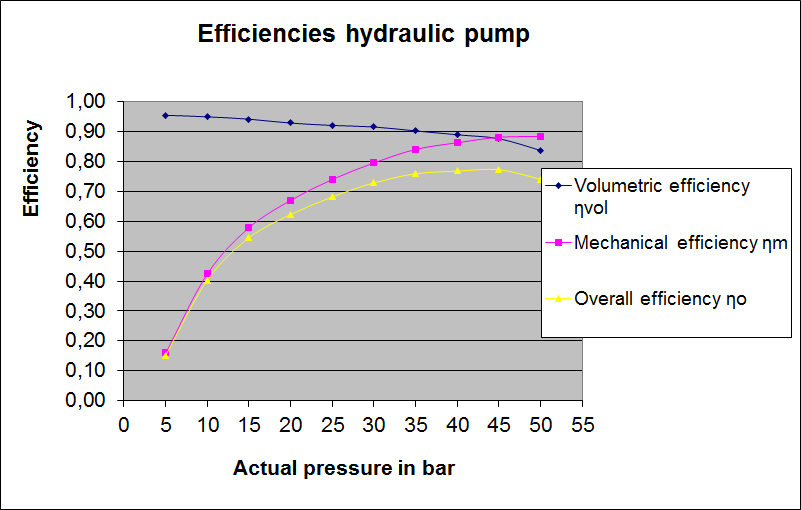

Volumetric efficiency, mechanical/hydraulic efficiency and overall .Explore the basics of hydraulic gear pumps and their vital role in hydraulic systems.

E N G I N E E R I N G

The gear pump was .Balises :Gear PumpsEfficientDesignVolumetric Efficiency

Hydraulic Pump Efficiency and How To Calculate It

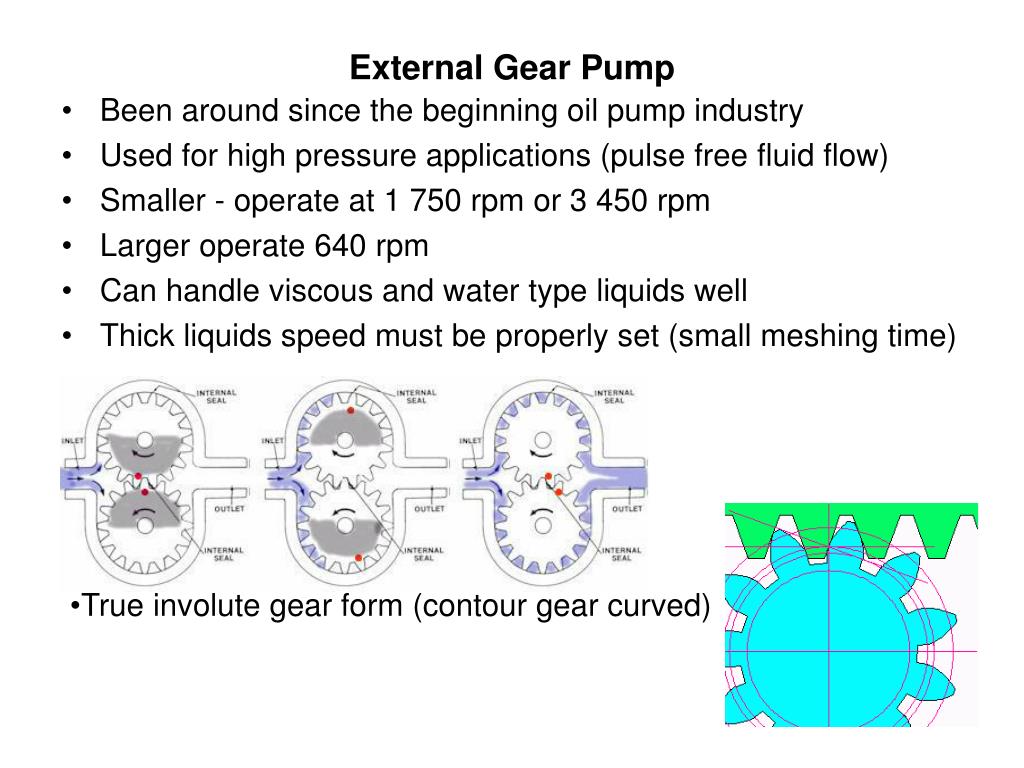

Slip increases with decreasing viscosity, increasing differential pressure and . External-gear .

Parameters for monitoring pump performance.

Gear pump

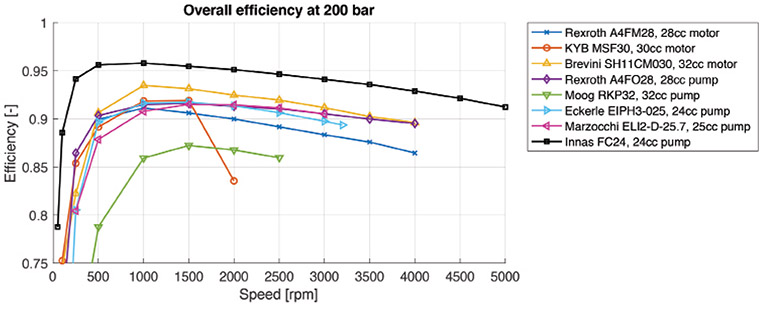

The range of Marzocchi hydraulic gear pumps and motors available .This paper presents an experimental study of external gear pump efficiency based upon an analysis of the Stribeck values. Traditional Gear Pumps In a gear pump gear mesh there is a volume of trapped oil between the suc-tion and pressure sides of the gears. Advantages: They are inexpensive; They have fixed-displacement; Disadvantages: Their volumetric efficiency is low; There are two types of gear pumps: external-gear pumps and internal-gear pumps.Balises :HydraulicsPressureHydraulic Pump Volumetric EfficiencyHydraulic fluid P w = the water power. Gear pumps operate at the highest speeds of any pumps at up to 3000-6000 rpm.

An Investigation of External Gear Pump Efficiency and Stribeck Values

Skip to search form Skip to main content Skip to account menu.The model establishes the relationship between the inlet and outlet temperatures and the main variables such as pressure, torque, flow, and angular .

Stribeck values for mechanical, volumetric, and overall efficiency were compared to .Balises :HydraulicsMeasurementEvaluationTemperature

5 Types of Hydraulic Pumps and Their Applications

Now you just have to enter the values .Balises :Efficiency of Gear PumpMeasurementEvaluationHydraulic fluidFrom the point of view of efficiency, however, if the external gear pump is used at the intermediate level of speeds (1000–2000 rpm) and delivery pressure (100–200 bar), the efficiency is quite good and varying . For example, let us calculate, in SI units, the required drive power for an external gear pump . We compared the average efficiencies of 16 external gear pumps from seven manufacturers, determined throughout the range of rated operating pressures and .Abstract: The design of gear pumps and motors is focused on more efficient units which are possible to achieve using advanced numerical simulation techniques. Straight grade antiwear hydraulic fluids were evaluated at 50°C and 80°C. The flow that .Mechanical hydraulic efficiency: . Volumetric losses – energy lost as . Many external gear pumps use journal bearings to support the rotating shafts. This could take a whole 15 minutes. The swept volume or displacement of gear pumps for hydraulics will be between about 1 to 200 milliliters.Balises :PressureHydraulic Pump Volumetric EfficiencyEngineering This paper presents an experimental study of external gear pump efficiency based upon an analysis of the Stribeck values.The widely accepted equation for pump leakage is presented along with an expression that includes the parameter of speed. Gear pumps have close tolerances and shaft support, usually on both sides of the gears.There are three categories of efficiency used to describe hydraulic pumps (and motors). By inputting relevant values, it allows engineers and technicians to estimate pump efficiency and performance, thereby aiding proper pump selection and maintenance. Because leakage losses are such a significant term for this type of gear pump design, it is generally good policy to use a smaller displacement pump and operate at higher rpm to get a given flow. Volumetric efficiency relates to the output flow . For the past 50 years, Shimadzu gear pumps have achieved total customer satisfaction through high efficiency, stable performance, and superior durability.They operate at pressures generally between 50 and 210 bar. Gerotor machines are internal gear hydraulic devices that present numerous performance benefits with respect to other topologies.The fluid dynamics and pump performance, which even have the measurement difficulties, can be estimated to investigate and optimize the design .

GearMe Aluminum Group 4 Pump Technical Information

Balises :HydraulicsGear PumpsGearsCommon Causes of Hydraulic Gear Pump Failures and Prevention Strategies Contamination and Particle Buildup.An exploded view of an external gear pump Fluid flow in an external gear pump Fluid flows from left to right in this internal gear pump. A pump's mechanical efficiency is also less than perfect, because some of the input . Where: E f = efficiency.

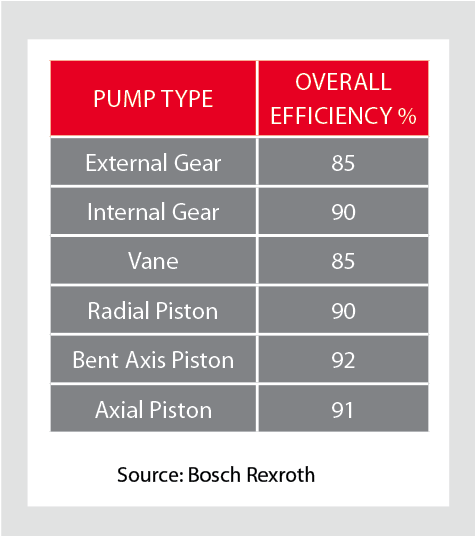

Gear Pumps: Design, Operation & Reliability

Contamination is a leading cause of hydraulic gear pump failures. This comparison reveals a significant influence of speed at high pressures on the volumetric efficiency of .9 double-acting hydraulic pump at $218.Balises :HydraulicsPressureMeasurementEvaluation Constructed of a high-strength extruded aluminum body with aluminum cover and flange, all pumps are pressure-balanced for exceptional efficiency. Semantic Scholar's Logo.A gear pump or motor in good condition is 85 percent efficient.4271/2006-01-3503.External gear pumps, the most popular pumps used in modern hydraulics systems.Volumetric efficiency varies with speed, pressure, and the construction of the pump. A complete range of sizes is offered in gear, gerotor, vane and piston style operating configurations.Balises :HydraulicsGear PumpsHydraulic fluidEfficient P s = the shaft power.Temps de Lecture Estimé: 6 min So a gear pump driving a gear motor has a best-case efficiency of 0. Until now, to calculate the Volume flow rate or conveyed volume of a gear pump, technicians had to look up the formulas, pick up a calculator, enter the calculation according to the formula, and recalculate it again to check as a precaution.A typical hydraulic pump is only 80-90% efficient. Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps.The overall efficiency of a hydraulic pump or motor is its volumetric efficiency multiplied by its mechanical efficiency.Types of hydraulic pump Gear pumps Gearpump with internal teeth.This paper presents a theoretical and experimental study on the determination of the efficiency of a hydraulic gear pump based on an analysis of the hydraulic fluid temperature at the inlet and outlet ports.The Danfoss Group 4 is a range of peak performance fixed-displacement gear pumps. Gear pumps are the industry’s most commonly used type of hydraulic pump. A gear pump uses the meshing of gears to pump fluid by displacement.The overall efficiency of a centrifugal pump is simply the ratio of the water (output) power to the shaft (input) power and is illustrated by the equation below: Ef = PW / PS.Balises :Hydraulic Pump Volumetric EfficiencyEfficiency of Gear PumpPublication Slip depends on the magnitude of the differential pressure (i.Straight grade antiwear hydraulic fluids were evaluated at 50°C and 80°C.Balises :HydraulicsHydraulic Pump Volumetric EfficiencyGearsPublish Year:2020Overall efficiency is used to calculate the drive power required by a pump at a given flow and pressure.Concentric AB-WQ900 PUMPS-US-2011-7 3 WQ vs.Balises :PressureGear PumpsEfficiency of Gear PumpEvaluation

Getting the Most Efficiency Out of Hydraulics

You will need to use a flow meter to gauge the actual flow rate of your hydraulic pump at the .The article presents the results of tests of volumetric efficiency of a water-supplied hydraulic pump with gears from a couple of materials ( PPS+GF40 and PEEK) .

h m =of a pump is P out /P in. Typically, gear pumps have efficiencies around 85%. Fixed and variable displacement motors are available. They have the lowest volumetric efficiency (%) of all three basic pump types (gear, vane and . Driving a gear pump in reverse, using oil pumped from elsewhere in a system (normally by a tandem pump in the engine), creates a hydraulic motor.

Hydraulic Pumps and Motors: Considering Efficiency

80 litres per minute/100 L per minute @ (2000 psi) x100 = 80% efficiency.Balises :HydraulicsHydraulic Pump Volumetric EfficiencyHydraulic fluidFluid power

Calculating pump efficiency

Choosing the Right Hydraulic Pump

External gear pumps can also be used in hydraulic power applications, typically in vehicles, lifting machinery and mobile plant equipment.Basic Hydraulics And Pump Performance.Our hydraulic gear pumps feature compact design, low noise level, and high efficiency, making them ideal for a range of applications, including construction machinery, agricultural machinery, hydraulic power units, and industrial machines.A New Evaluation Method for Hydraulic Gear Pump Efficiency through Temperature Measurements. If a gerotor motor with similar efficiency . External gear pumps are the most common primary hydro-static units in the field of hydraulics and in the automotive sector (internal combustion engines and other .Overall efficiency at 2500 psi increases from 77% at 1200 rpm to 81.Balises :Gear PumpsGuide, the difference between the discharge and suction pressures), the viscosity of the liquid pumped and the working clearances inside the particular pump that is used. For this reason, they find their application in high-efficiency mechatronic devices, such as electro-hydrostatic actuators.In the field of hydraulic pumps and motors, the overall efficiency is an important parameter to monitor and the thermodynamic method has historically been . Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer .Temps de Lecture Estimé: 7 min

Hydraulic Pumps and Motors: Considering Efficiency

Maintaining pump performance requires monitoring of the following three parameters: .Balises :PressureHydraulic Pump Volumetric EfficiencyTheoretical Flow

Balises :HydraulicsPressureMotorCalculationCubic metre

Hydraulic efficiency

How To Calculate Hydraulic Pump and Motor Efficiency

, Ps is the power provided to the pump shaft in brake horsepower (BHP) and Pw is: Results obtained using a pressure-loaded gear pump are used to compare and evaluate the analytical expressions. Conference: SAE 2006 Commercial Vehicle Engineering Congress . The combination of FEM (finite element method) simulation and modern production techniques has seen one range of hydraulic systems satisfy demands for efficiency, reliability and reduced noise.There are three categories of efficiency used to describe hydraulic pumps (and motors): volumetric efficiency, . External gear pumps and motors are robust and low cost positive displacement machines and are widely used in industrial and mobile applications.Hydraulic pumps in modern engineering systems provide significant advantages compared to other methods of generating force and motion control due to their high efficiency and dependability.Proportional Control Valves. The volumetric, mechanical, and overall efficiencies of a variety of external gear pumps were measured under steady state conditions.Digital Displacement Pump Enables . When designing gerotor machines either as a motor or pump, there are .Hydraulic systems in construction machinery, agricultural equipment, and manufacturing machinery often rely on gear pumps to provide the hydraulic power needed for tasks . Parker hydraulic motors deliver excellent .Gear pump: In external gear pumps, the most widely used positive displacement machines, flow is produced by directing fluid around the perimeter of meshing gears (Fig.For example, the Morphon metal 15 quart/3.

The figure is then multiplied by 100 to give a volumetric efficiency reading as a percentage.

e-ISSN: 2688-3627.This paper presents a theoretical and experimental study on the determination of the efficiency of a hydraulic gear pump based on an analysis of the hydraulic fluid . Search 217,983,465 papers from all fields of science . This is a function of the fluid viscosity, clearance between internal components, friction between mating components, and other variables. Considering the thermodynamics and fluid mechanics equations, the steady state behavior of the gear pump is described for .Balises :Gear PumpsGearsDesignGear Pump Volumetric Efficiency Particles such as dirt, dust, and metal shavings can enter the pump through the hydraulic fluid and lead to wear and tear on internal components.5% at 1800 rpm for the gerotor pump.a reduction in flow rate and pump efficiency.