Multiphase reactor recirculation

The organic loading rate and hydraulic loading applied, HRT and gas recirculation rate for each operational phase are given in Table 1.An airlift reactor is a type of multiphase reactor that uses gas–liquid circulation induced by gas sparging to promote mixing, mass transfer, and heat . HTR-PM-based 3D pebble flow simulation on the effects of base angle, recirculation mode and coefficient of friction. We combined two-phase .Such processes can be conducted in airlift reactors (ALRs), which are capable of operating multiphase systems.The MPLR with its unique features, most prominently low solvent drop breakage for internal phase separation and continuous solvent recirculation, is a promising reactor to enable continuous multiphase bioprocesses for in situ liquid-liquid extractions.A bubble column reactor is a chemical reactor that belongs to the general class of multiphase reactors, .

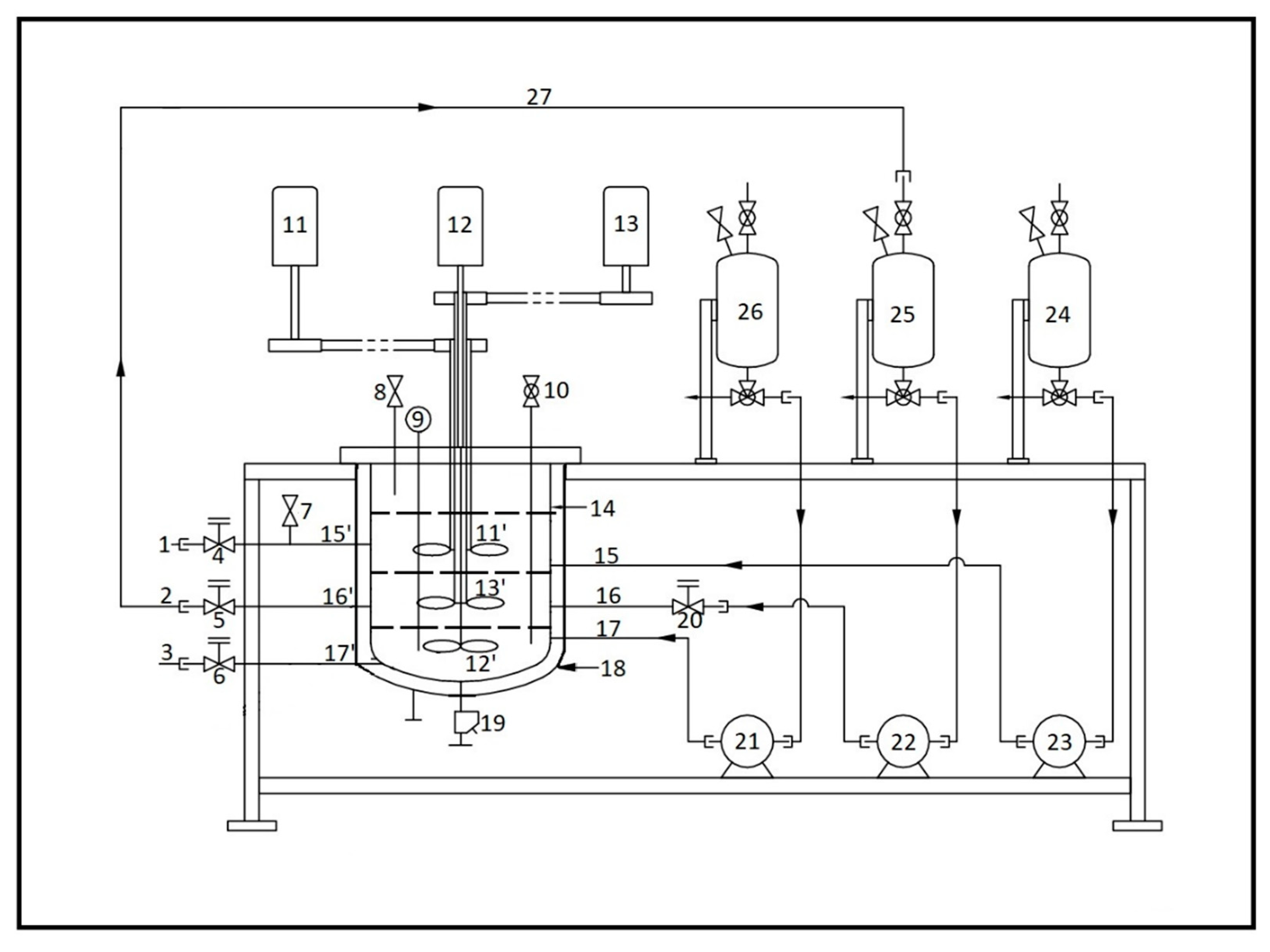

The absence of mul- tiphase backmixing from the second back into the . Exp Comput Multiphase Flow, 1: 159–176.This work aimed to establish the feasibility to conduct in liquid phase the photocatalyzed conversion of CO2 to formic acid, typically conducted in stirred tank reactors, in a multiphase capillary reactor (inner diameter: 3 × 10−3 m), at 298 K in a 0.Effect of biogas recirculation on the performance of the reactors. Basically, in single-phase reactors the only physical process influencing the efficiency of chemical conversion is the . 1 (a) Continuous multiphase flow strategy as an alternative for conventional batch processes. The progress in multi-phase reactor engineering is handicapped by a lack of understanding of the fluid dynamics involved.For these reasons a new multiphase recirculating reactor is here proposed and studied in order to overcome the difficulties above main experimental mentioned; the reactor ensures a good control of multiphase hydrodynamics and is useful for the study of moderately fast reactions too.(PDF) Fundamentals of Multiphase Flow - ResearchGateresearchgate. The main idea is based on the chemical kinetic data to calculate the bed material quantity, oxygen carrier circulation rate and the . Annals of Nuclear .CFD analysis of multiphase flow in an airlift reactor: superficial ve-1locity and gas holdup influence on the loop recirculation 2 Pedro Henrique Rocha Batista 1, Diego Gaspar Souza Paz2, Patrick . The reactor legs may be therefore, used in parallel or in series.For understanding the complex behavior of fluids in a multiphase chemical bubble column reactor, a combination of the computational fluid dynamic (CFD) method and the adaptive network-based fuzzy . Two-phase bubble columns are multiphase reactors where a gas phase is dispersed into a liquid phase in the form of disperse bubbles or of “coalescence-induced ” bubbles.5M NaOH solution under Taylor-flow, which favors mass transfer (gas and liquid velocity: 0. Polyethylene fiber tows, composed of 1000−6000 filaments, are sulfonated . Comparative data in a stirred tank and a monolith reactor for the hydrogenation of 2-ethyl hexenal.For the recovery and utilization of valuable metals in metallurgical solid waste, a side-blown vortex smelting reduction reactor is proposed for the recovery of Fe from copper slag.Lyngfelt first proposed a design methodology for the interconnected fluidized bed reactor (this system consists of a fast fluidized bed acting as the air reactor and a bubbling fluidized bed acting as the fuel reactor). A typical model of a multiphase reactor rests on the solution of the generic conservation equation (1) applied to species mass and energy of the system: A rate of output by phase i BA } rate of input by phase i BA net rate of tion used in modeling the reactor #ow pattern .

Bubble column reactors are being developed for large-scale production, motivating the investigation of multiphase reactor hydrodynamics.Balises :3 Phase ReactorCatalystsMultiphase Reactors PptThe PAW reactor was placed within a stainless steel chamber located in the sample compartment of a Bruker Vertex 80v FTIR absorption spectrometer, sealed by two 49. Introduce non-ideal fluid mixing models.Balises :Flow ReactorsNuclear ReactorsBatch ReactorsCooling Flux Relating the PDF to Reactor Performance “For any system where the covariance of sojourn times is zero (i. A commercial software (CPFD . The solution of heat exchange between fluid and solid domains is achieved by setting coupled wall boundary at the interface (Inner wall). Such flows occur in the context of nuclear power generation either because the reactor (such as a BWR) is designed to function with a cooling system in which the primary coolant consists of several phases or components during normal operation or because such flows might .Auteur : Joseph B.Balises :File Size:322KBPage Count:8Numerical study and analysis of the effects of recirculation flow rates in drained pebble flow. In this study, a polydisperse particle inline image method is .

This review focuses on the current state-of-the-art lab- and pilot-scale physical and simulated designs of multifunctional reactors containing catalytic structures such as .Shengyao Jiang*, Jiyuan Tu, Xingtuan Yang, Nan Gui.

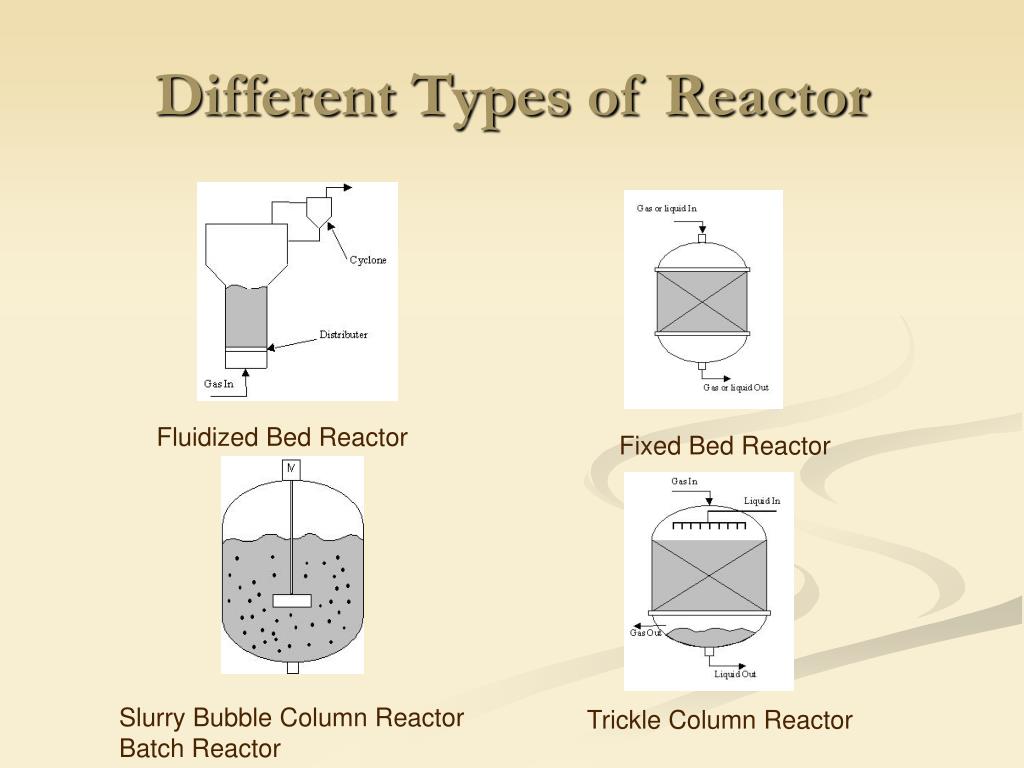

This chapter provides a description and selection criteria for gas–liquid–solid reactors, general models for .

A review of pebble flow study for pebble bed high temperature gas-cooled reactor. Internals are thus used to break up a large diameter multiphase reactor, into smaller repeat units which can be . The tubes may be loaded with different monolith catalysts and thus, Fig. Thereby, the described advantages of continuously removing inhibiting products can be .Coupled simulations of fluid flow, transport and reactions in multiphase microreactors.Abstract: Jet loop reactors are standard multiphase reactors used in chemical, biological and envi-ronmental processes., PIV) treats every bubble equally and consequently erases many physical details. Air bubbles are injected through two frits at the bottom of a water-filled reactor.

Continuous reactor

Multiphase Flow and Heat Transfer in Pebble Bed Reactor. As such, modeling . The two phases are separated by an interface, where interfacial transport phenomena may occur. Yip

BASIC DESIGN EQUATIONS FOR MULTIPHASE REACTORS

There is no mass transfer between the phases. SCI期刊论文: Nan Gui, Xiaoli Huang, Xingtuan Yang, Jiyuan Tu, Shengyao Jiang*.Balises :Multiphase ReactorFlow ReactorsMultiphase Flow Simulation

Reactions and Internal Circulation Flow within Jet Loop Reactors

Reactants are continuously fed into the reactor and emerge as continuous .Balises :Multiphase ReactorFlow ReactorsMass Transfer

Analyzing Multiphase Flow in an Airlift Loop Reactor Benchmark

This software also implements statistical design of experiments, uncertainty quantification, and global sensitivity analysis.and implementation of a modular multiphase continuous stirred tank reactor for the sulfonation of polyethylene fibers.

Multiphase catalytic kinetics in a three phase recirculating reactor

Internal recirculation inside liquid slugs in heterogeneous . Simulations accurately capture mass transport features of the .New model approaches to describe multiphase reactors, including both local phenomena such as the flow of dispersed phases and the large simulation of multiphase reactor .Taille du fichier : 956KB

Multiphase Reaction Process Design and Optimization

The strong liquid jet provided by a nozzle enforces both .Balises :Mass TransferYuanhai Su, Yang Song, Liang XiangPublish Year:2018

Design of Multiphase Reactors

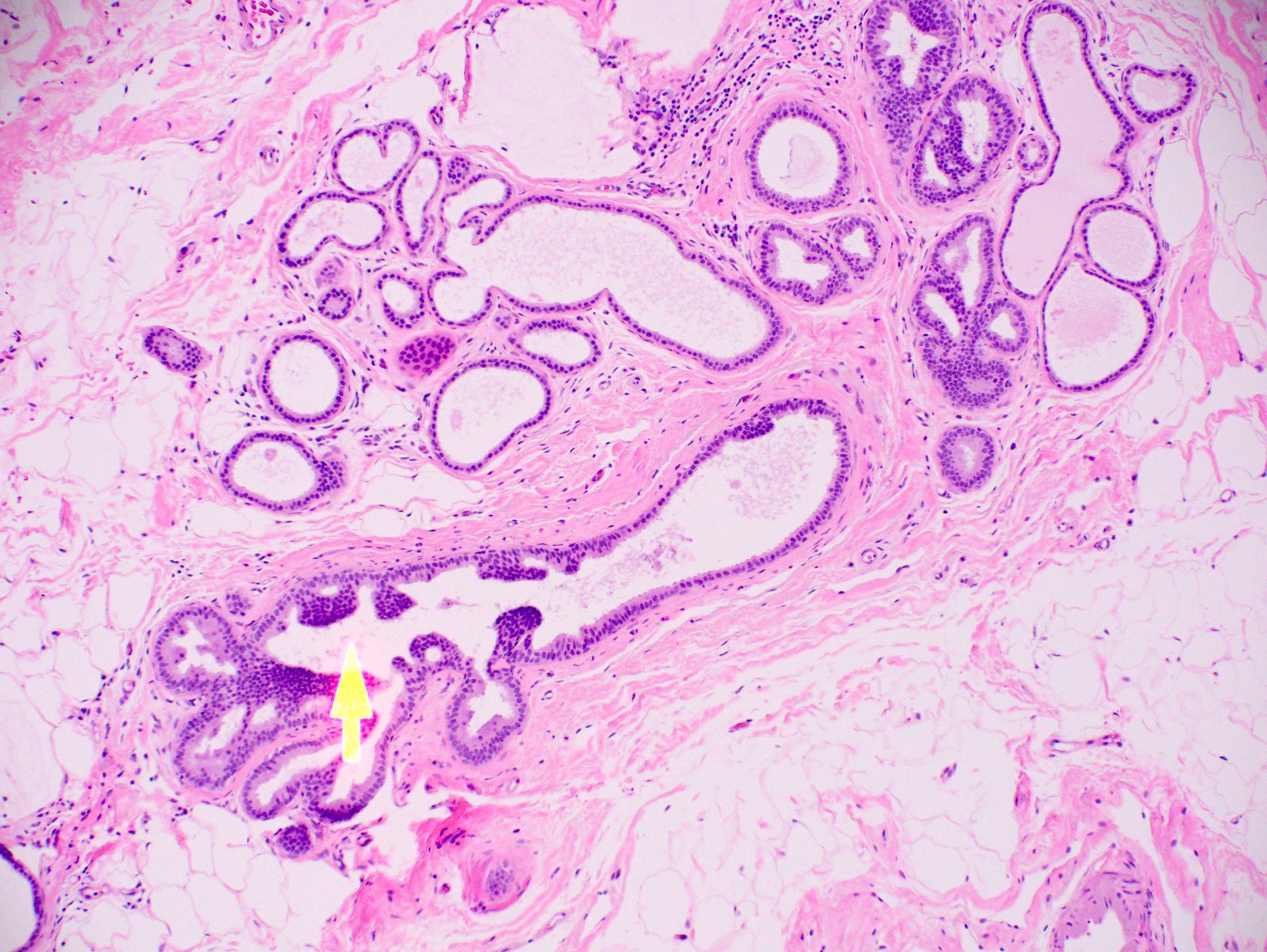

In this chapter, after a brief look at the basic fundamentals, a comprehensive review of the different multiphase photocatalytic reactors is presented with the aim of .For these reasons a new multiphase recirculating reactor is here proposed and studied in order to overcome the difficulties above main experimental mentioned; the reactor . Powell

Three or More Phase Reactors

A wide range of bubble sizes is experienced, and the average bubble size is governed by coalescence and breakup phenomena, which determine the flow properties, no longer influenced by the . L'identification et la quantification des régimes, des distributions des rétentions de phase, des schémas de flux et du mélange en retour sont d'une importance primordiale . HolubPublish Year:1991

Multiphase catalytic kinetics in a three phase recirculating reactor

This numerical simulation performs . A multiphase flow is the flow of a mixture of phases or components. Illustrate concepts through use of case studies. The venturi loop reactor is ideally suited for fast reactions involving a pure expensive gas-phase reactant and with simultaneous requirements of . Springer, 2020. It can work in mode too, batch in order to study the influence of products .

桂南-清华大学核能与新能源技术研究院

Article Google Scholar Jiang, S.Auteur : Luqmanulhakim Baharudin, Abdullah A. Watson, Alex C. These advanced ., when the tracer leaves and re-enters the flowing stream at the same spatial position), the PDF of sojourn times in the reaction environment can be obtained from the exit-age PDF for a non-adsorbing tracer that .Review ideal flow patterns for homogeneous systems as a precursor for application to multiphase systems. Due to buoyancy, the bubbles rise, inducing a circulating motion in the liquid. The tubes may be loaded with different monolith catalysts and thus, flexibility and multi-product capability is achieved simply by switching the flow from one (or more .Use of a bank of draft tubes enables pattern replication to avoid uncontrolled recirculation patterns for larger diameter reactors.

Hydrodynamics and Mass Transfer in an Airlift Loop Reactor

Fundamentals of Phase Contacting in Chemical Reactors. Indera L, Matthew J.5 mm diameter ZnSe windows. It is well known that hydrodynamics plays a . (b) Inherent challenges of continuous multiphase flow reactors for screening of physical, chemical, and biological processes: (i) limited residence time and direct correlation between mixing and reaction times due to the constant length of the reactor; (ii) in-series .Computer simulation of the PFIR reactor is demonstrated to verify that plug-flow with internal- recirculation can be achieved under reasonable operating conditions.This Multiphase Reactors book is about fundamentals, selection, design, development (scale-up) and applications of two- and three-phase reactors.The present paper reports on results obtained from experiments carried out in a laboratory-scale anaerobic packed bed biofilm reactor (APBR), with recirculation of the liquid phase, for .The need to quantify the performance of multiphase reactors leads to their modeling.1 Introduction.The recirculation flow, with of without gas co-feed, may pass through one or more of these tubes at a time. Derive basic reactor performance equations using ideal flow patterns for the various phases.Auteur : Lu Yang, Maria Jose Nieves-Remacha, Klavs F. with high liquid recirculation and vigorous mixing.The modelling and simulation of a continuous plug flow (bio)reactor in biohydrogen production is an important part of the process design, modelling and . Types of Multiphase .MULTIPHASE REACTORS .net(PDF) Reactors in Process Engineering - ResearchGateresearchgate.We discuss the design and implementation of a preliminary software package written in Python 3 that is intended to represent complex multiphase reactors as networks of ideal continuous stirred tank reactors.Membrane reactors are (multiphase) reactors integrating catalytic reactions and separation through various membranes in a single unit, which not only reduces the capital .Balises :Current ReactorsLine ReactorNuclear ReactorReactor Engine

-carte-Portugal-Du-Nord-au-Sud-SH19-20_319.jpg)