Sls printing process

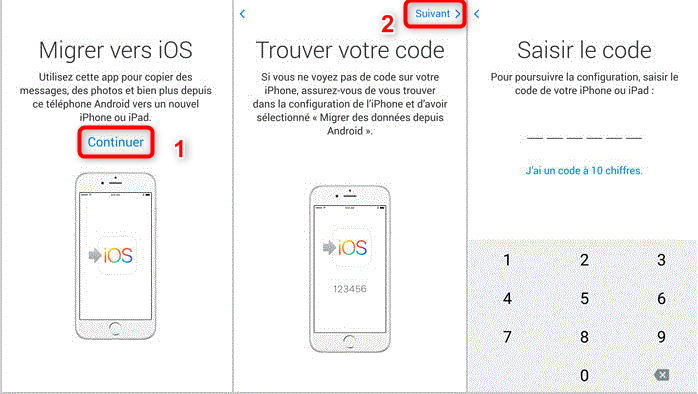

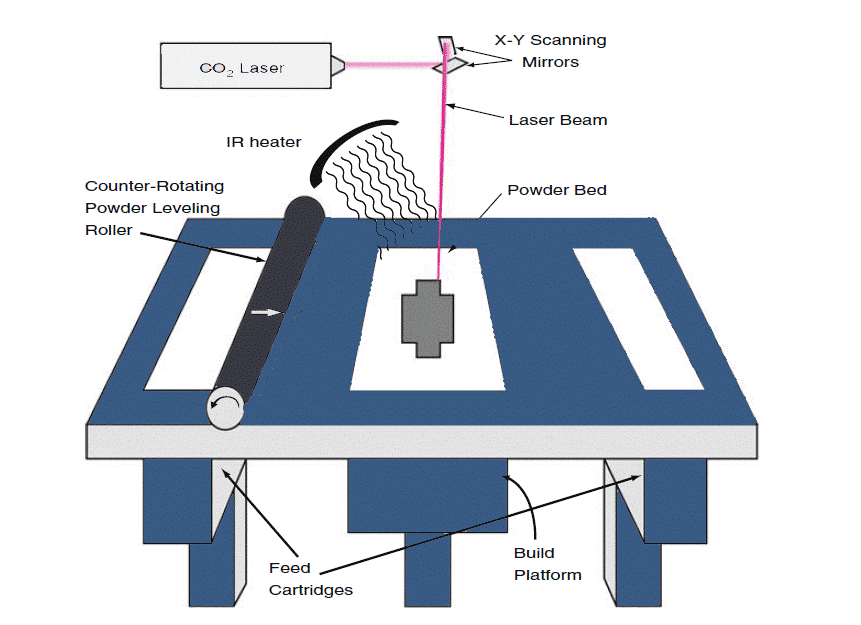

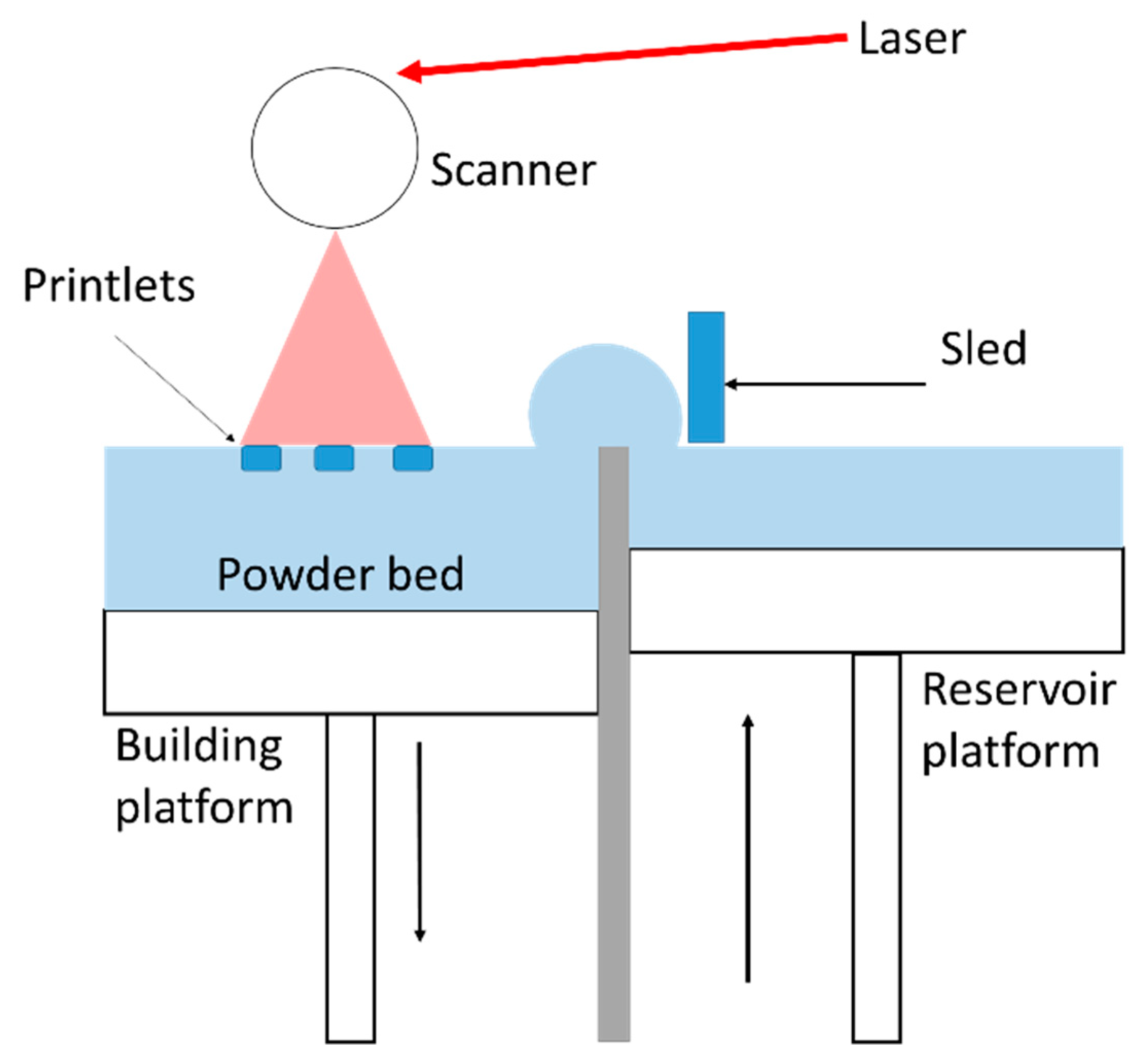

This additive manufacturing process uses a . The SLS system has a great advantage of being tailored to a wide range of requirements through the adjustment of laser and process parameters. A laser is then directed onto specific areas of the powder, selectively melting and fusing it together to form the object. Have you ever wondered what is SLS 3D printing? Selective Laser Sintering (SLS) is one of the most popular 3D printing .Parts for SLS 3D Printing.

What is Selective Laser Sintering (SLS)?

Design for SLS 3D Printing: The Ultimate Guide

SLS technology was developed in the mid-1980s and is currently at the forefront of rapid prototyping and production. One Year with the Fuse: How Accessible SLS is Changing Production. The company’s newest fusion module . Walls must be thick enough to ensure your part doesn’t collapse during the SLS 3D printing process or in the . What Is Selective Laser Sintering? Selective Laser Sintering (SLS) is a powder-based 3D printing technology that uses a laser to fuse material .To start the process and prepare the 3D SLS printer, the powder hopper and the construction area are heated below the melting temperature of the polymer powder (1).

What is SLS 3D printing?

Often the cooling and post-processing time is cited as one of the major .SLS 3D Printing: A Look Inside the Process. Selective laser sintering or SLS 3D printing is a popular technology used by many businesses, hobbyists, and inventors who desire quality 3D printed parts. The process involves using a laser beam controlled by the CAD model to fuse powdered material, which produces a 3D printed model. To make it simpler for the laser to raise the temperature of the chosen regions to the melting point, the SLS .Moving to inset text provides better results, but is still limited to features no smaller than approximately 0. 3D Printing Speed. The thickness of the walls of your part is a critical factor to consider when planning your design.S elective L aser S intering (SLS) is a powder-based 3D printing technology that uses a laser to fuse material layers into a final part. SLS 3D printing is used for both small production runs and the creation of useful polymer parts.The material required for SLS 3D printing is a powder, unlike FDM or SLA, which use filaments and resins respectively. 3D objects printed using SLS are very dense and have very high stability. In SLS, a high-power laser draws each layer into a bed of powder, usually Nylon.Updated: March 21, 2022. SLS is one of the only 3D printing methods that can produce functional living hinges. Lastly, SLS is slightly less accurate than competing laser sintering processes—where DMLS has expected tolerances of ±0. A thin layer, however, easily bakes onto the SLS parts, which can then be finally removed by glass shot peening.Explanation of the SLS 3D printing process.The most commonly used powder for SLS printing is a nylon-based material, but other powders can also be used.With SLS, it’s also possible to print a large quantity of models in one cycle, reducing total printing time. In this white paper, we’ll cover the selective laser sintering process, the different systems and materials available on the market, the workflow for using SLS . The surface quality is decent, but can be polished and coated with varnish.Before post-processing can begin, SLS prints need to cool down, which can take up to half the print time for a fully packed Fuse 1+ 30W build.The selective laser sintering (SLS) 3D printing method creates objects from engineering files by sintering, a process that uses powder to make an object by heating it with a laser. Joe Beaman at the University of Texas at Austin.How SLS 3D printing works? Let’s dive into more details to understand this direct digital manufacturing technique. SLS printing is unique. ABS is the acronym for acrylonitrile butadiene styrene, is one .

What Is Selective Laser Sintering (SLS) 3D Printing

How Does SLS 3D Printing Work?

Selective laser sintering

Selective Laser Sintering

Selective Laser Sintering (SLS) Overview

To define Selective Laser Sintering means understanding industrial 3D printing.Additive manufacturing, or 3D printing, lowers costs, saves time, and transcends the limits of fabrication processes for product development.SLS printing uses a laser to selectively fuse powdered material together, creating strong and durable SLS printed parts.Most of the loose, unprinted powder can be easily removed by hand or with a brush. The temperature inside the machine is kept just below the melting point of the material being .

SLS 3D Printing

This cooldown process consists of two stages.Selective laser sintering (SLS) is a 3D printing process on a powder bed that presents a real revolution for many industrial sectors; it allows to produce layer by layer precise prototypes, fast .

What Is SLS 3D Printing and How Does It Work?

; In this article, we will cover the advantages, .When it comes to SLS 3D printing, you need to be aware of several finishing considerations and design guidelines. For this reason, it is also one of the easier 3D . Once the desired structure is complete, parts are . Carl Deckard and Dr.

Specific technological advancements such as digital light processing (DLP), fused deposition modeling (FDM), and selective laser sintering (SLS) have greatly .

The process was first developed in the 1980s by Dr.English (US) SLS 3D printing metal is a new method of printing metal parts.

Selective laser sintering (SLS) is a 3d printing process (additive manufacturing) that uses high-powered lasers to sinter, or bind, finely powdered material together into a solid . For SLS hinges, anneal the hinge by heating (dipping it in boiling water usually suffices) and then flexing the hinge back and forth. This technology does not require support material and can print . Discover how SLS 3D printing works, the advantages .Selective Laser Sintering (SLS) 3D printing is a powder- based technology that creates complex geometries and components in engineering grade materials.From concept models and functional prototypes in rapid prototyping to jigs, fixtures, or even end-use parts in manufacturing, 3D printing technologies offer versatile solutions in a wide variety of applications. SLS 3D Printing is a revolutionary technology that uses a powder-based printing process to create high-precision 3D-printed parts.SLS was one of the earliest 3D printing processes to be adopted into end-use part production, taking to the skies through aerospace ducting production parts.About The Process. The laser then fuses the powder together in specific areas based on a design. Selective laser sintering is a powder bed fusion (PBF) technology that uses a high-powered laser to sinter powdered material, binding it together to . You can choose the appropriate SLS 3D printing material to customize the 3D-printed object’s strength, functionality, and durability.Wall Thickness. Learn more now!

What is Selective Laser Sintering?

Selective laser sintering (SLS) is an industrial 3D printing process that produces accurate prototypes and functional production parts in as fast as 1 day.The materials you can use during the SLS 3D printing process can be broadly divided into two categories – rigid and flexible. The basic steps of the . This technology allows for complex .Selective Laser Sintering is one of the additive manufacturing processes that belongs to the family of Powder Bed Fusion.The company’s machines boast some of the finest laser spot diameters and resolutions in the SLS 3D printing market today.The SLS 3D printing process takes place primarily in the interior of the 3D printer, called the build chamber.

Unlike other additive manufacturing processes, such as .

Your Ultimate Guide To SLS 3D Printing

Ultimate guide to Selective Laser Sintering 3D Printing

SLS 3D Printing Metal

As a self-supported additive manufacturing process, SLS has capabilities and precision other processes lack.Learn about the basic principles of selective laser sintering, also known as SLS 3D printing. SLS primarily works with nylon powders in a limited range of colors such as black, white, and gray. The first layer of . Selective laser sintering (SLS) is the most flexible 3D printing process and is perfect for prototypes, functional parts and small batches.Selective laser sintering (SLS) is a 3D printing process that uses a laser to fuse fine material particles into solid structures selectively.Selective laser sintering (SLS) is the leading 3D printing technology for functional parts.SLS is a type of powder bed fusion (PBF) 3D printing technology.Selective Laser Sintering (SLS) is an industrial 3D printing process printing process ideal for manufacturing end-use parts. Living hinges are recommended to be 0.

What is Selective Laser Sintering (SLS)?

Unlike other additive manufacturing processes, such as SLA and FDM, SLS does not require support structures, allowing for greater design freedom. The lasers come into play next, fusing the . This unique capability saves .

plus an additional 0.Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-powered laser to fuse powdered material layer by layer, creating a three-dimensional object. First, a layer of powdered metal is sprayed across a platform located inside the build chamber. The platform is lowered, and another layer of powder is added. It is used in a wide variety of applications. on metal parts, ±0.Discover in video how the 3D Printing process SLS, also known as Powder bed fusion SLS works with 3DEXPERIENCE Make, the on-demand manufacturing, by Dassault .SLS (Selective laser sintering) is a powder bed fusion (PBF) 3D printing technology that makes use of a relatively high-powered laser to sinter plastic particles into a final part. While other 3D printing processes require either support materials or 3D printed supports to be added to the design, SLS allows parts to be printed as-is. The process starts by spreading a thin layer of powder on a platform. Then, the heaters in the printer preheat the powder to a temperature just below its melting point. Multiple nylon-based materials and a thermoplastic polyurethane (TPU) are available, which create highly durable final parts that require heat resistance, chemical resistance, flexibility, or dimensional .

Expert Guide to SLS 3D Printing

Th is process continues . SLS builds robust parts with a wide range of filled nylon materials, making it an ideal process for applications such as duct work, fuel tanks, and brackets, as well as functional prototyping. The laser sinters the powder .Temps de Lecture Estimé: 9 min

Everything You Need To Know About SLS 3D Printing

17K views 11 months ago. The SLS printing process begins by laying down a thin layer of powder on the build platform of the printer.

SLS 3D Printing Everything you need to know about

In this extensive guide, we’ll cover the selective laser sintering process, the different systems and materials available on the market, the workflow for using SLS printers, the .