Visual indicators for production lines

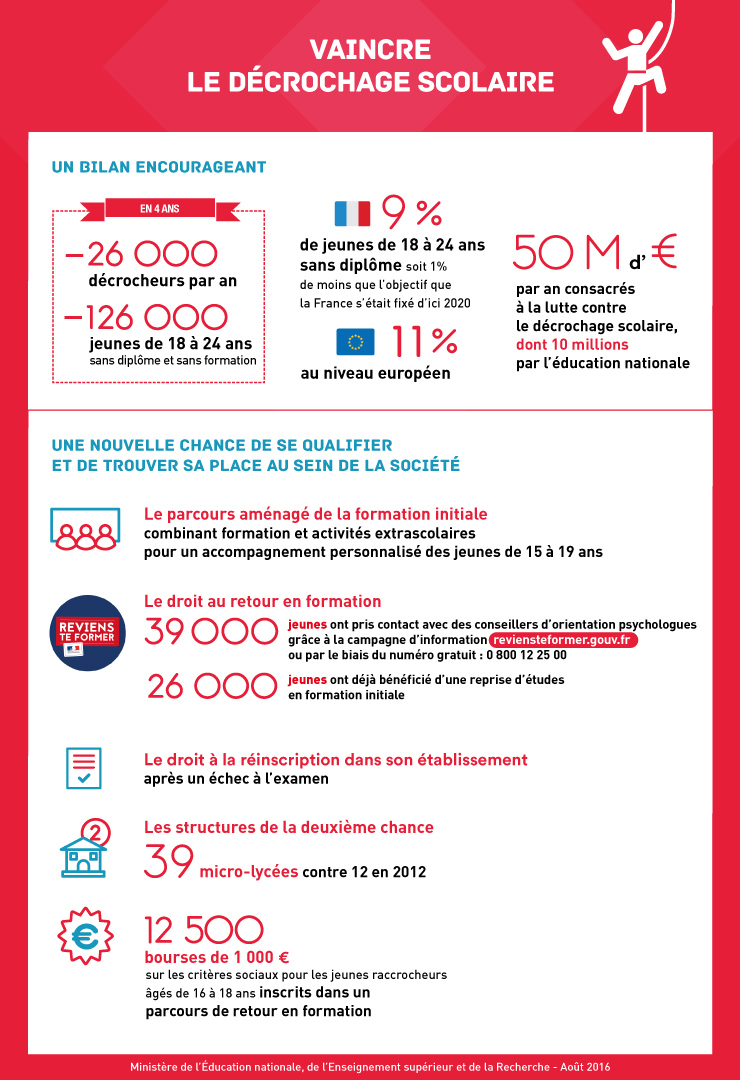

initiatives, efficiency gains can still be realized by borrowing lessons learned through the visual management techniques of those processes.This white paper discusses how visual management can drive productivity by leveraging seven common Key Performance Indicators (KPIs) for production line ., color-coded signs, labels), and floor markings are common visual tools .Type of indication visual-analogue, scale indication Weight 53 g Pressure setting or indication range-1 bar to 0 bar Permitt.

Lean Visual Management Tools: 5 Types of Visual Controls

33 Manufacturing KPIs & Metrics You Need To Track (2024)

Q: Can a Visual Factory be implemented in any type of industry or organization?A: Yes, the principles of a Visual Factory can be adapted to various industries, from manufacturing and warehousing to healthcare and service secto.Download Citation | On Mar 9, 2023, Alexandr M.

Visual Control For Production Line Paint

The focus indicator provided is a 12px thick line along each of the shortest side of an item.Visual management is focused on guiding people to make correct decisions. torque 10 Nm Switching type - Max.Visual management components in automated facilities serve three distinct functions — to convey actionable information on the condition of machines and processes in the production line, to give coded instructions to machine operators and other plant personnel, and to track production-line performance for better-informed enterprise-level .Critiques : 5

EconomyLine

How often should visual displays be updated in Visual Management?Visual displays should be reviewed and updated on a regular basis to ensure that they remain relevant and aligned with changing needs and circumsta.

7 Common KPIs For Production Monitoring

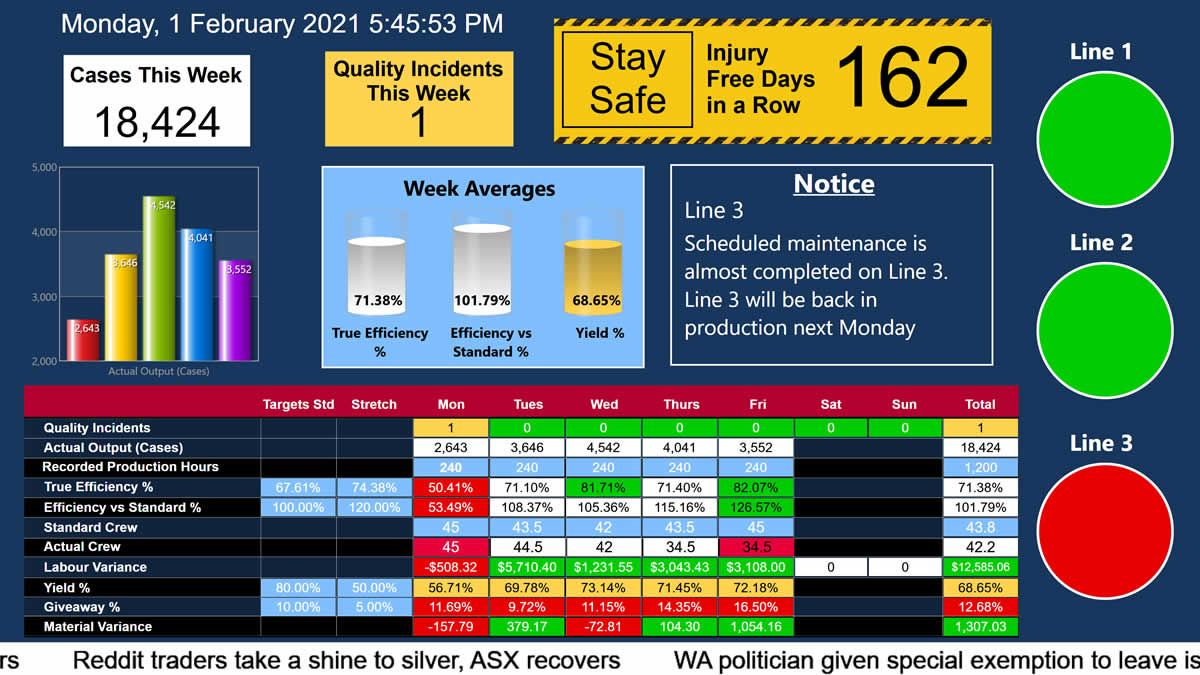

On this first manufacturing dashboard example, we will look at the overall production capacity of an organization.The temporal analysis of events in a production line helps manufacturing experts get a better understanding of the line's performance and provides ideas for imp Visual .

In the process industry, Takt time is calculated for .

7 Common KPIs for Production Monitoring

Track your progress with metrics on production, cycle time, downtime, quality, . Each line name, status, and component is controlled by the .In manufacturing, VM is made possible by communication devices able to return data about the state of a workplace, a machine tool, a group of machine tools (e. Effective communication, involving employees in the design process, and. It’s important because it.The indicator functionality in the Visual Production Scheduler allows to modify the main font color (from 27 available colors) of the planning table responding to individual business logic.Indicators are statistics used to measure current conditions as well as to forecast financial or economic trends.What are the benefits of implementing Visual Management?Improving communication, streamlining processes, increasing productivity, improving safety, reducing waste, and improving overall operational effic.Q: How can I measure the success of a Visual Factory implementation?A: Success can be measured through key performance indicators (KPIs) aligned with the objectives set at the beginning of the project. Indicator on operation “20” of production order line “1011002 – 10000” with font color blue . However, there are specific situations in which this type of visual communication is vital to avoid errors in .850811

Forex Line Trading

The Top 7 Key Performance Indicators. To achieve this, we present a visual analytics approach to iteratively decompose event logs to find recurring event patterns.Forex line trading – The Ultimate Guide 2024. This white paper discusses how visual management can drive productivity by leveraging seven common Key Performance Indicators (KPIs) for production line monitoring.

The Visual Factory: Managing Production

Hence, also for this product, the top production methods and excellently trained personnel with contemporary expertise are available.Q: How long does it take to implement a Visual Factory?A: The time to implement a Visual Factory depends on the complexity of the operations, the scope of the project, and the resources available.7 to 0 bar continuous Permitt.

A Complete Guide to Andon in Lean Manufacturing

Visual indicators, such as colours and floor markings, are one of the simplest ways to convey information in your workplace, allowing employees to locate equipment or determine production status with just a glance.

Guide: Visual Management

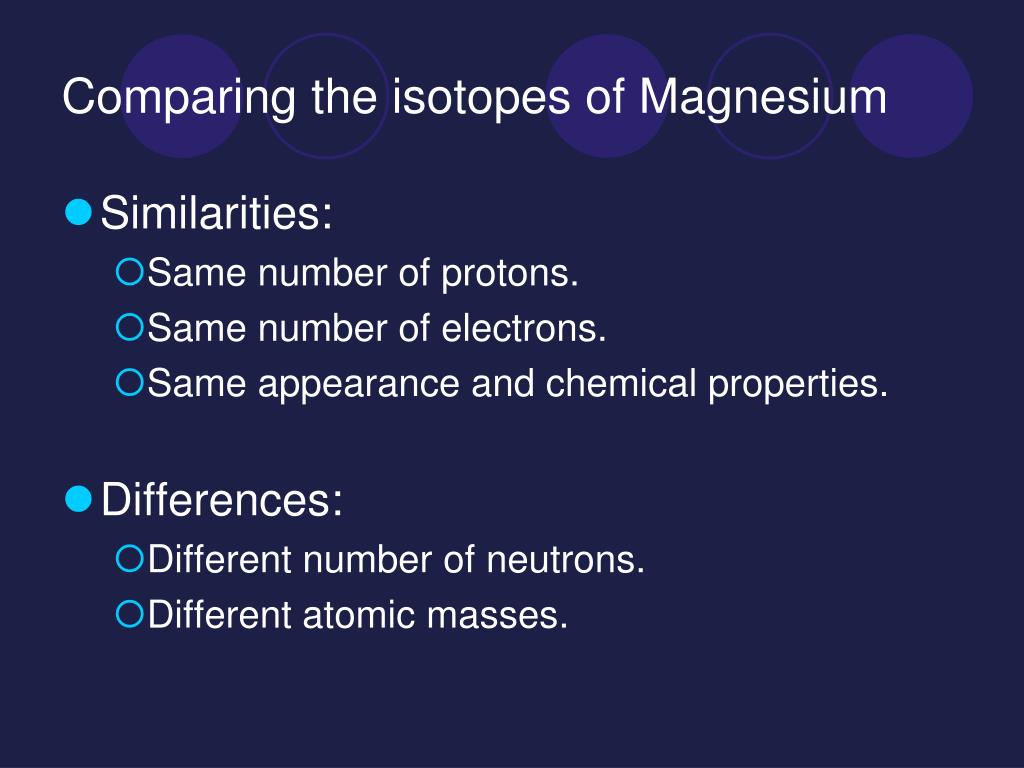

An application transforming production line data into a .This paper focuses on this situation, supporting employees visualizing and navigating production line data. These visual management tools help track the efficiency of assembly lines, identify bottlenecks, or monitor the usage of resources, providing supervisors with a . The indicators increase productivity and .Flow lines, not paced production lines, are commonly used in the process industry. Technical analysis involves using various tools and indicators, and one of these tools is the concept of lines.Floor Markings: Crucial for delineating specific areas, paths, or zones within the factory, ensuring safe and efficient movement of both personnel and machinery.This article explains how to set up and use an example Blox widget that creates a dynamic visual representation of a production line. Augmented reality based .

temperature range -20 °C to +60 °C Thread G 1/ 8 Max.

Evo Visual Indicators

Overall Equipment .

Visual Analytics for Production Line Failure Detection

Visual representations for key performance indicators (KPIs) at the unit process, factory, and organizational levels, also facilitate decision-making for MSA [133, 134]. Forex line trading typically refers to a type of technical analysis used in the Forex, stocks, and cryptocurrencies trading. The idea primarily refers to visual lines drawn on a price . A Hierarchical structure of key performance indicators for operation management .Q: What if employees resist the changes associated with implementing a Visual Factory?A: Resistance to change is common, especially when introducing new systems. Employee involvement. Optionally, format the KPI by selecting the paint brush icon to open the Format visual pane. 9 Production Key . altering a metric at one machine might affect performance at another machine. Count (Good or Bad) 2.The term Visual Factory refers to a lean manufacturing principle that emphasizes the use of visual information to streamline operations and enhance . Having at your fingertip all the important key performance indicators related to the production of your company provides a great overview that helps optimizing it. You can choose whether to modify the font color in the table area on Production Order Lines level and/or on operation level in the Gantt area.

“Production line” status indicators

Production Downtime: .A 2px thick perimeter around an item is equal to 4×187+4×42 = 916px. They help traders make informed trading decisions by .

Understanding lean visual management tools

What is a Lean Manufacturing KPI? Why Your Company Needs to be Using Production KPIs. Visual cues need to be straightforward and understandable for everyone on the production floor, regardless of their role or level of expertise. It is adaptabl. For example, when you have the same item on two production lines, and you schedule quantities on the first production line but not the second line, the system does not display colored schedule grid cells for the second production line. Learn how to calculate 40 manufacturing KPIs.Popular market indicators include Market Breadth, Market Sentiment, Advance-Decline, and Moving Averages.Open Production Dashboard in Fullscreen. Visual management also provides actionable information . The colors of .To help visualize their data, manufacturers often implement a variety of production dashboards. switching voltage at resistive load .

Based on the information they provide to us, these visual elements can be classified in different groups: Visual signals, which aim to explain to us what we are . เห็นทุกกระบวนการผลิตแบบ Real time เหมือนอยู่ในไลน์ผลิต, ข้อมูลครบมี Report ง่ายต่อการนำเสนอเพื่อ Impovement, ควบคุมทุก Line ผลิตได้ผ่านหน้าจอ Computer . To add a goal, drag Total Units Last Year to the Target field.What Is a Technical Indicator? Technical indicators are used traders to assess likely price movements.When the screwdrivers fail, the possibility of line production stop has been considered, when the Jolly intervention is needed on the left side of the second station . They can be simple, like the simple moving average (SMA) indicator. By displaying this data on the factory floor, employees have a better sense of production levels and tend to strive for higher performance. Measuring manufacturing quality involves Quality KPIs like yield, perfect order percentage, and customer reject rate, which evaluate the degree to which products conform to their intended specifications.

Manquant :

production linesLeading and lagging indicators: what you need to know

Definition of an Indicator Object. This may include color-coded components, labeled areas .

6 Manufacturing Dashboards for Visualizing Production

Start Your 30-Day Free Trial.Alternate production lines without active orders are not colored for POH.Popular leading indicators include: The relative strength index (RSI) The stochastic oscillator.Color Coding

Guide: Visual Factory

The area of each line is 12×42 = 504px.Quality is one of the most important metrics to track.

Manquant :

visual indicatorsSeven Common Production KPIs.Manufacturing KPIs & Metrics

Sokolov and others published Integrating Performance Indicators to Track the Production Development of Manufacturing Lines | Find, read and cite all .Graphs and charts (e. WEKA manufactures all its products at its own plant in Switzerland. This is the percentage of products that emerge from the production line with defects. switching voltage - Electrical connection - Max.

Manufacturing KPIs: 40 Key Production Metrics You Should Know

Callout value - controls the indicator's display units, decimal .

How It's Used, Types, and Examples

In these environments there is usually one machine which sets the pace of a flow line which we call the Drum (in-keeping with the rhythm idea of Takt and also aligning Takt with key concepts in the Theory of Constraints).& Business Excellence (2013): T owards an extended set of production line performance indicators, T otal Quality Management & Business Excellence, DOI: 10.These KPIs serve as leading indicators for production performance, tracking defects at every stage of the production cycle.Our goal is enable production experts to find and understand long-term issues of production assembly lines.

Here’s a look at some of the quality KPIs you need to track: Percentage Defect.

Filter Clogging Indicators

References [1] Kang N, Zhao C, Li J, Horst JA. An optimized production line is of no use if the products created don’t live up to your company's standards.

Manquant :

production linesTechnical indicators are math calculations on certain parts of a stock’s performance.

What role does employee engagement play in Visual Management?Employee engagement is essential in Visual Management because it fosters ownership, participation, and continuous improvement.There are several benefits of visual management being implemented within Lean Six Sigma projects and in general in the workplace.