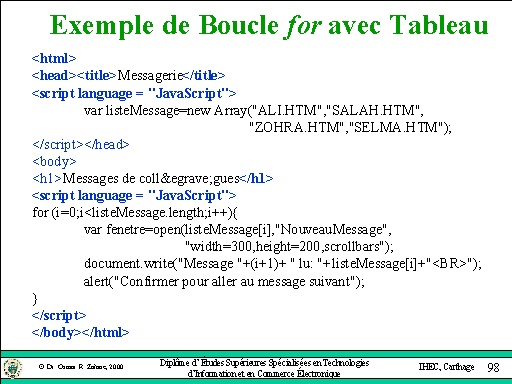

Wenger thermal extruder blades

More available energy for more output. Wenger Blades absolutely guarantees all of its knives and axes against breakage of any kind under normal usage. Wenger DDC preconditioner. Additionally, these systems are coupled with a high intensity preconditioner (HIP) which provides less .

Knife Specifications: Overall Length: 7”. Specs/Features; 250 hp Main drive: X-165 w/Model 16 DDC: Request Information/Pricing. According to the company, the extruders provide exceptional performance with a broad range of raw materials. 250 hp Main drive.Project Design & Support (CPS) We utilize unmatched knowledge, resources and experience to address the entire scope of your extrusion-based project. Sanitary configurations available. Note: Two (2) seals are required on the inlet head. A smart and economical upgrade for your older style Wenger extrusion system, the Dust Tight Downspout is designed and manufactured to elimimate gaps or air leaks and maintain dust-free operation from start-up to full operation. Weigh belt offers continuous weighment.Wenger Automated Process Management (APM) Process control refers to the techniques and systems used to maintain and regulate the output of a process within a desired range.Two counter-rotating shafts that provide gentle mixing and conveying of the product. Blade Length: 3. Adjustable air flows for optimal processing control and efficiency. These canvas pouches are handmade by Lester River Bushcraft and come in a Frogskin Camo pattern.Brochure_Extruder_Wenger SX Optima - Free download as PDF File (. In most cases, Wenger can help you navigate your way through the development process faster than you could do it alone - allowing you . Theirs was the first extrusion cooking system and the basic .AquaFLEX is the industry's most flexible extrusion system for aquatic feed, enabling production of floating, slow sinking, and sinking products using a wide range of ingredients and recipies.The Magnum ST Series redefines versatility for smaller extruders with no loss of capacity.

Optima

Magnum ST Twin Screw Series

Specs/Features. Savings in excess of $50,000 in reduced installation time and errors have .Increase Efficiency of your Wenger Preconditioner by Combining Steam and Water into a Single Injection Process. This solution enables constant monitoring and logging of product temperature data via Wenger's APM control system and safe diversion of product in the extruder that does not meet the correct temperature requirement.Wenger X-165 Extruder. Two available models: AFX-3000, AFX-600. (AFX-3000) Pellet sizes of 0. We re-engineered the extruder's drive components and .northern-crops. If you experience failure of any kind with your Wenger Blades product please contact me and I will make arrangements for . Blade Length: 2.Wenger’s extruder boasts speeds of up to 1,200rpm and power levels to 165kW hr/t SME at volumetric capacity.

Wenger Blades

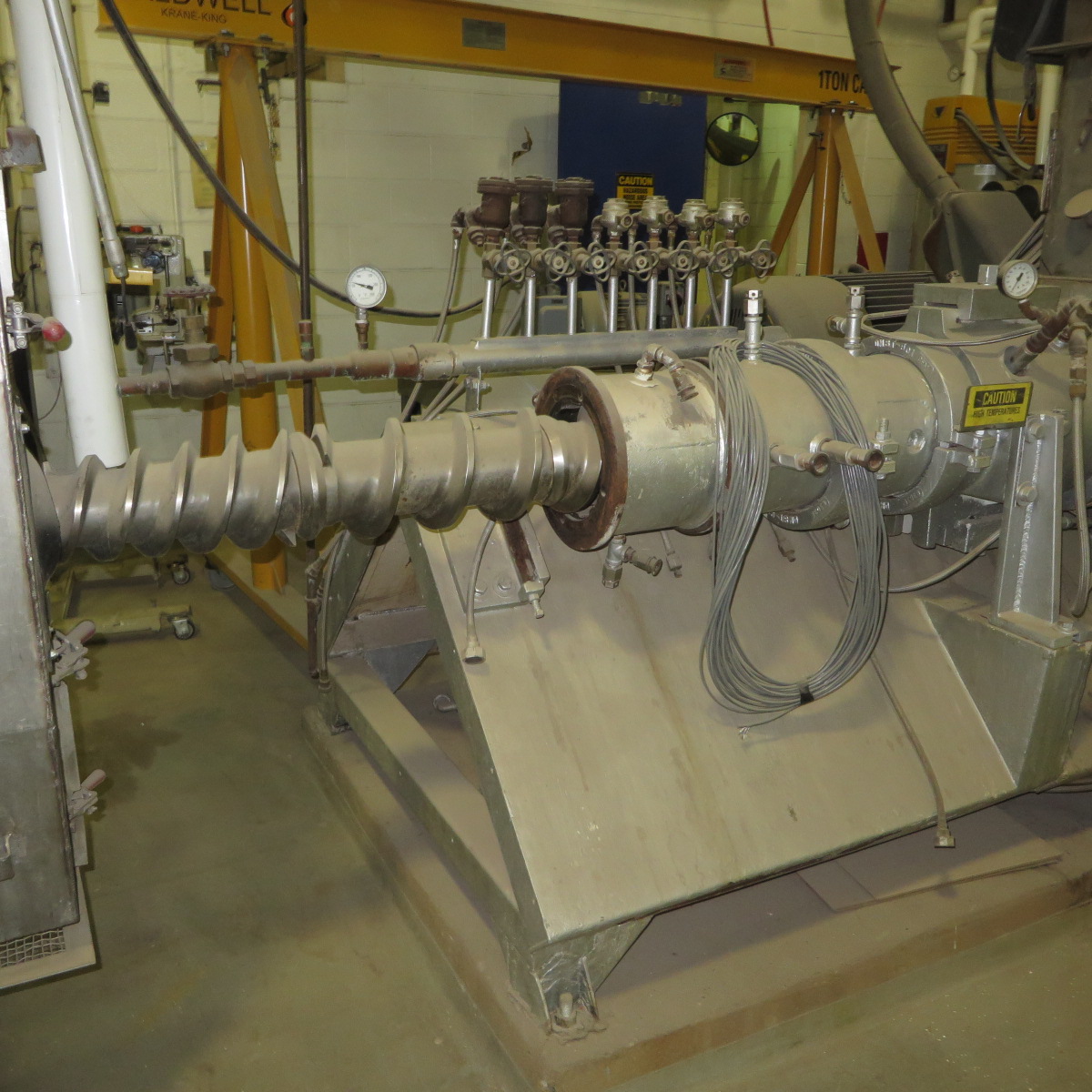

2004 Wenger TX-85 Twin screw extruder. The Thermal Twin process offers new opportunities in . Each major equipment component includes an electrical junction box with control devices pre-wired to terminals. Le système d'extrusion Thermal Twin® est adapté aux fabricants . standard injection. L/D: Model 16 DDC preconditioner: Numerous spare parts: Vacuum vent stuffer : Vertical knife drive: Plumbing rack: Request Information/Pricing. For additional information regarding this process, contact Wenger Manufacturing at: [email protected] II - The industry standard for post-extrusion drying/cooling. Benefits of the Magnum ST Extruder include potential for lower bulk density, higher absorbency levels of liquid coating, smaller cell structure, enhancement of textural properties and higher cook levels.

High Capacity Horizontal Dryers/Coolers

The SMI can be retro-fitted to an existing Wenger HIP or HSC preconditioner models, or .Precision Engineered and Manufactured to Eliminate Dusting during Startup and Operation. Wenger X-165 extruder with a Model 16 DDC. Spare heads, sleeves, screws and dies included. With a little ingenuity and a lot of hard work, brothers Joe and Louis Wenger founded Wenger Mixing Company in a small Kansas .Forming Extruders. The second product demonstrated was a high-meat, grain-free, jerky treat recipe with . These modules come skidded and ready to connect to your steam and water service.TX-85 Wenger Twin Screw Extruder. Enclosed, sanitary design (316 SS) to meet food safety regulations. X-165 w/Model .

Steam/Water Mixing Injection (SMI)

The Multicarry . Optimize the liquid application absorption and . variable depth adjustment.

Dust Tight Downspout

Wenger X-175 Extruder.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Wenger Thermal Twin Process

Overall Length: 10” Blade Length: 5.

Control Systems

variable convey time. Press 1 for other options and then press 2 again for US/Canada replacement parts.TWIN SCREW EXTRUDER, WENGER 52. 6 In Feed screw (SS)

Aquatic Feed

a Wenger parts representative will be able to assist.aaronequipment. Comes with a Multi Carry Options sheath and Pocket Carry sheath.

Manquant :

Wenger Blades absolutely guarantees all of its knives .Twin screw extrusion for petfood and aquafeeds

Intensified mixing results in smaller particle sizes into the extruder, more uniform product moisture, and more consistent heating.Wenger Technical Center professionals have the knowledge and skill to help you develop, test, analyze, and produce new product prototypes and develop processes that enable new product manufacturing at full scale.Wenger TX-52 Twin-Screw Extruder — Northern Crops . Maximum level of ingredient and formula flexbility. Our partner Extruder Experts expands its portfolio with extruder wear parts .La flexibilité est la clé et la base des systèmes d'extrusion bi-vis de la nouvelle génération de Wenger. View the full product →. The ability to use higher SME (Specific Mechanical Energy) settings to take extruded . Two independently driven shafts of different sizes.Wear parts for Wenger extruders. They are compatible with our Northwoods Bowie, OSS, Smatchet, and Tracker sheaths.This simple, econonmical upgrade can improve your operations, extend the life of your extruder, and reduce maintenance costs and downtime.

With a standard inlet valve . Inventory Classification. Contact seller.Different sizes and Part Numbers for different extruder models; 4-18 blades; Blades can be omitted for production, but blade spacing must be equidistant; EXAMPLE: 12 blade . They went on to design a machine that blended molasses with dry feedstuffs and produced pellets in 1948.More than 40 years of experience have resulted in refinements to Optima Single Screw Extruders.For US & Canadian Customers: Dial +1 785 284 2133.

Overall Length: 7.The Wenger Diverter Valve provides an effective and convenient way to divert wet material during the start up phase. Tech & Production. (69) 100% positive.

The kibble production line included a Wenger Thermal Twin-Screw extruder, a Convection Roaster (CVR), a multi-pass dryer, a Bulk Density System (BDS) and an .

Manquant :

thermal extruderA prepackaged plumbing module is provided with every Wenger extruder.txt) or read online for free.Micro Tracker

Manual Control panel.115” Nitro-V or CPM 3V.The Wenger High Intensity Preconditioner (HIP) provides an advanced level of mixing and control that makes it the perfect complement to Wenger extruders. Name * Company * Email * Phone * Address * Street Address Address Line 2 City . With a little ingenuity and a lot of hard work, brothers Joe and Louis Wenger founded Wenger Mixing Company in a small Kansas (USA) town in 1935.All Wenger Blades hawks are made from 3/8 80 CrV2 tool steel and machined to achieve the optimal weight distribution for the most efficient chopping. Heat source can be gas, steam, or electric. The Steam/Water Mixing Injection (SMI) system was created by Wenger to provide a more efficient preconditioning process with reduced maintenance.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket . Contact Wenger at +1 785 284 2133 and ask about our inlet head assembly upgrade.The Thermal Twin cooking extruder and the process for extrusion cooking of cereal grains having limited cold-water viscosity are patent pending. tall gravity feed bin (SS) Non agitated.

It involves monitoring and adjusting various variables such as flow rate, temperature, pressure, and other factors to ensure that the process operates within established . Infrastructure. Don't let a worn inlet seal interrupt your operations.United States (USD $) Australia (USD $) Austria (USD $) Belgium (USD $) Canada (USD $)

Manquant :

thermal extruder

Seller's other items. Previous article.

Replacement Parts Detail

To complete the feed production process, the AquaFLEX can be paired with a Wenger high volume horizontal dryer.

Collections

email: domesticparts@wenger. Specs/Features; Year MFG 2004: 200 Hp.

Manquant :

thermal extruderWear parts for Wenger extruders

ETM is especially important in production of . Doug Baldwin explains how Wenger Manufacturing have expanded the role extrusion .Extrusion Temperature Monitoring (ETM) is a useful upgrade for any Wenger extruder. Powder coating option. Today, these extruders assure greater production potential with more available energy through the unique design of the screw flighting and barrel ribbing. Wide variety of configurations, materials, and sizes. Benefits of the Magnum ST Extruder include . For flaked cereals, the forming extruder receives material from the twin screw extruder, while jacketed barrels and hollow flight screws permit cooling of the cooked .

The self-cleaning extruder screws act as a vapor lock to seal the inlet, allowing a high pressure to be generated and therefore a high volume steam escape.

Plumbing & Wiring Module

Wenger extruders are engineered to operate in thermal to mechanical energy ratios from 1:1 to as much as 14:1. This is achieved with a twin-screw profile that .